Mixed liquid treatment method and recovery method

A treatment method and mixed liquid technology, which is applied in water/sewage treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problem of high sulfate content in micro-etching waste liquid, increased evaporation system load, and incomplete removal of heavy metals and other problems, to achieve the effect of reducing the burden of disposal, reducing the concentration of sulfate radicals, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

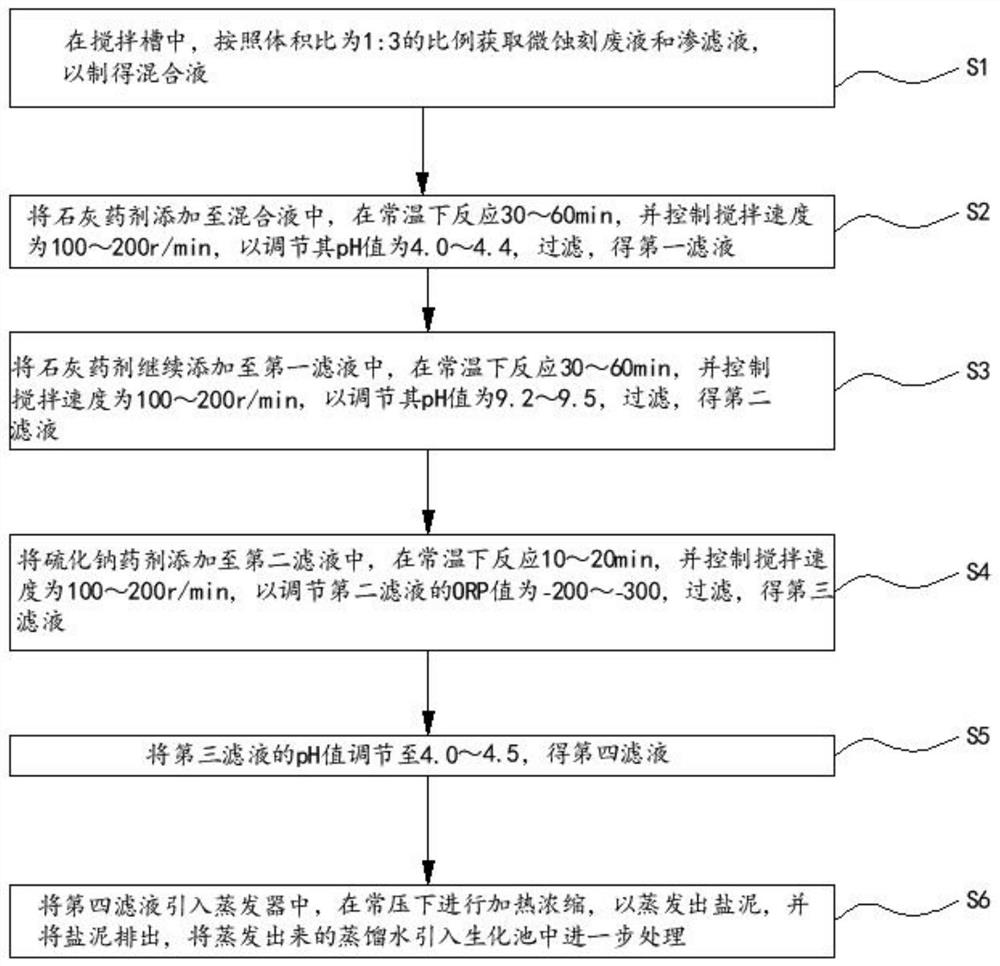

[0029] Such as figure 1 Shown, a kind of processing method of mixed liquor, comprises the following steps:

[0030] S1. In the stirring tank, microetching waste liquid and leachate are obtained according to a volume ratio of 1:3 to prepare a mixed liquid.

[0031] After testing, the micro-etching waste liquid and leachate were mixed according to the ratio of 1:1, 1:2, 1:3, 1:4, 1:5, filtered after sufficient reaction, and the content of sulfate in the filtrate was detected. The test results show that the higher the proportion of leachate, the lower the sulfate content in the mixture. When the ratio of the two is greater than 1:3, the sulfate content basically does not change significantly, indicating that the solution has fully reacted at this time. Therefore, when the mixing ratio of micro-etching waste liquid and leachate is 1:3, it can not only e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com