Precast concrete module hoistway for additionally arranging elevator and construction method

A prefabricated concrete and hoistway technology, which is applied in vertical pipelines, infrastructure engineering, and building material processing, can solve the problems of long construction period, large safety hazards on the construction site, and high construction costs, so as to reduce labor costs and shorten the construction time on site. The effect of reducing construction time and reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The technical solution will be further described below in conjunction with the accompanying drawings and specific embodiments, so as to help understand the content of the present invention.

[0052] Please refer to Figure 1-14 , Embodiment 1 of the present invention will be described below.

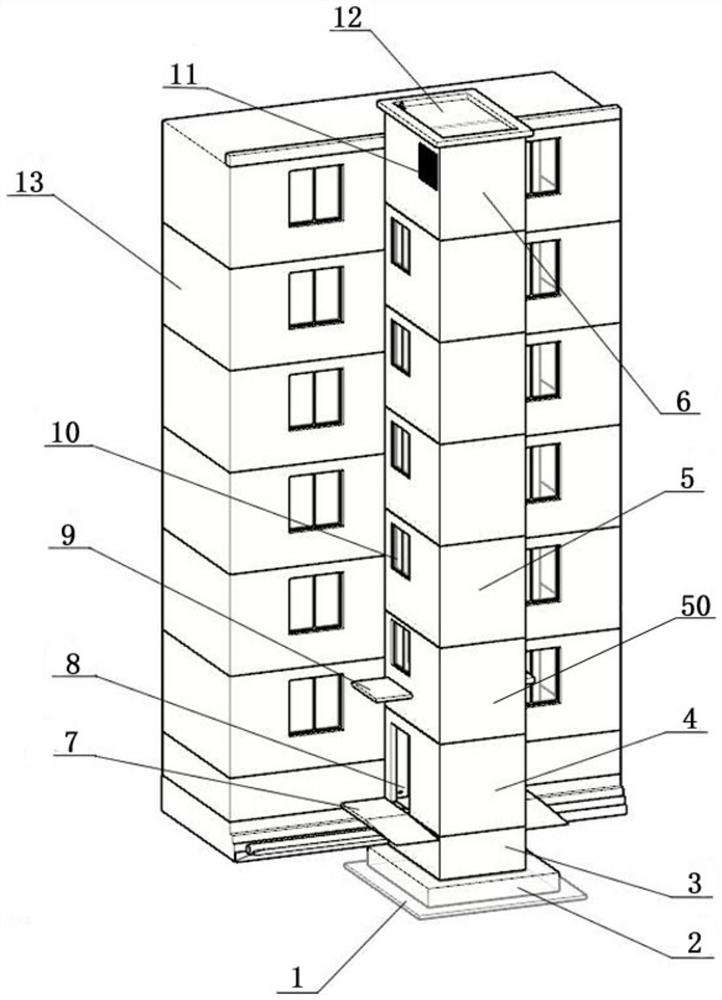

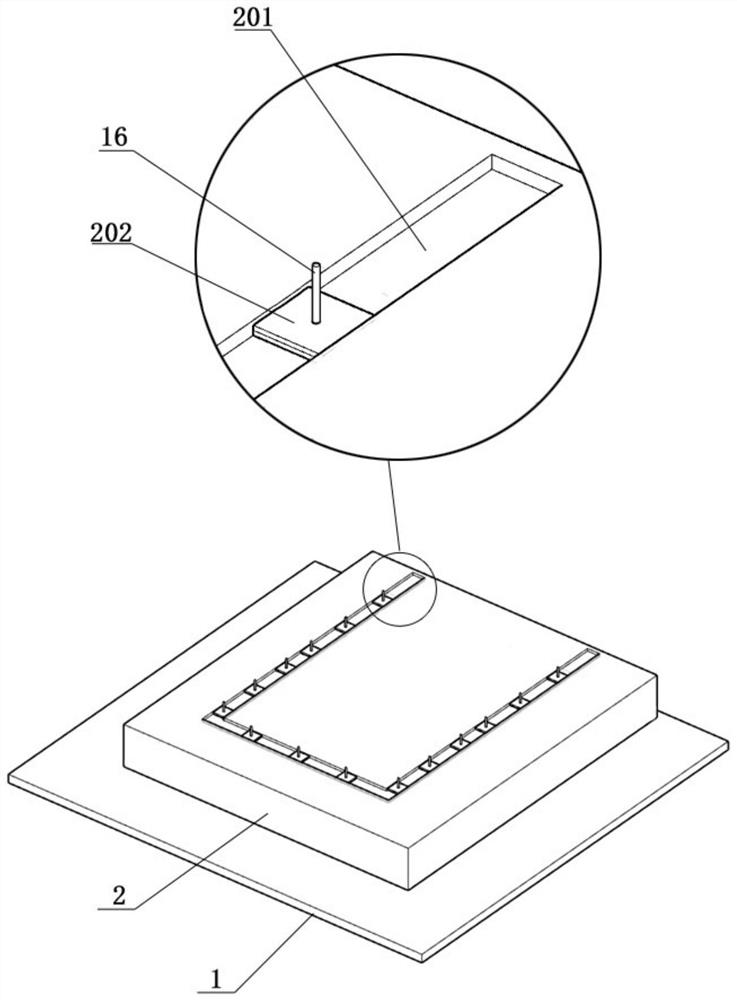

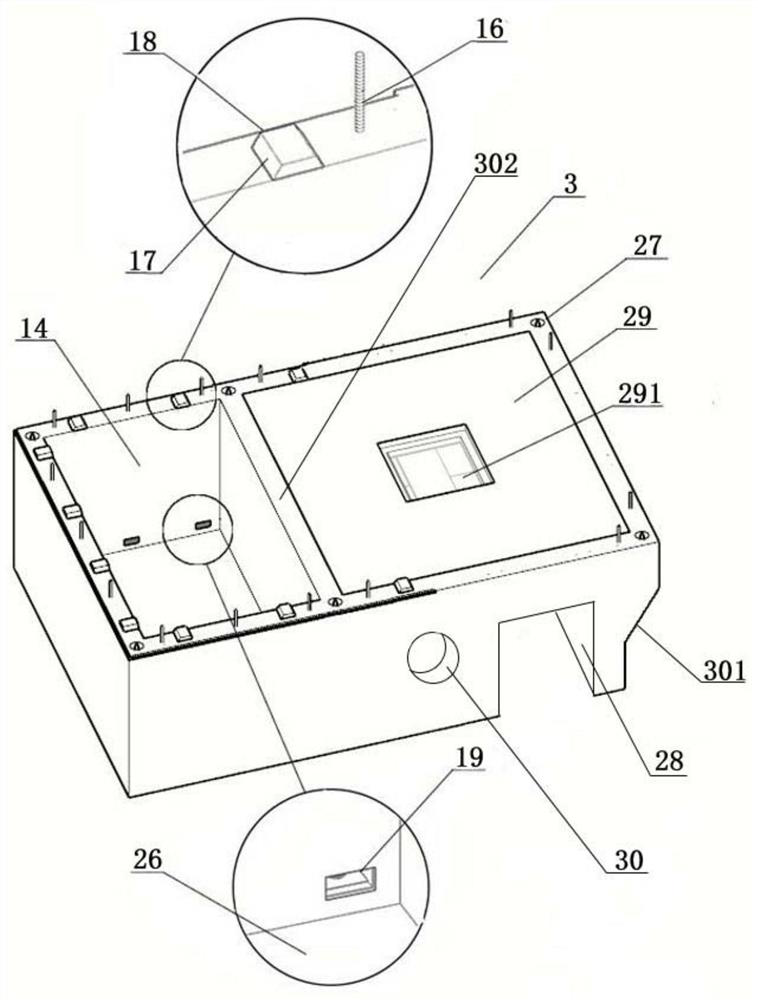

[0053] Such as figure 1 As shown, the present invention proposes a modular concrete elevator shaft. First, the foundation tunnel is dug on site, and then the foundation cushion 1 is poured on the spot and the foundation raft 2 is poured on the foundation cushion 1. The modular concrete The elevator is installed on the foundation raft 2, and in order from bottom to top it includes a foundation section module 3 connected to the foundation raft 2, a first floor section module 4 connected to the foundation section module 3, and the first floor section module 4 connected to the foundation section module 3. The section module 4 is connected to the adjustable module 50, four standard s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com