Suspended reverse wall working well supporting structure and construction method

A technology of supporting structure and construction method, which is applied to earth-moving drilling, shaft equipment, wellbore lining, etc., can solve the problems of insufficient structural stress system, difficult construction, limited application scope, etc., to achieve reasonable stress and avoid uniform soil quality. requirements and ensure the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

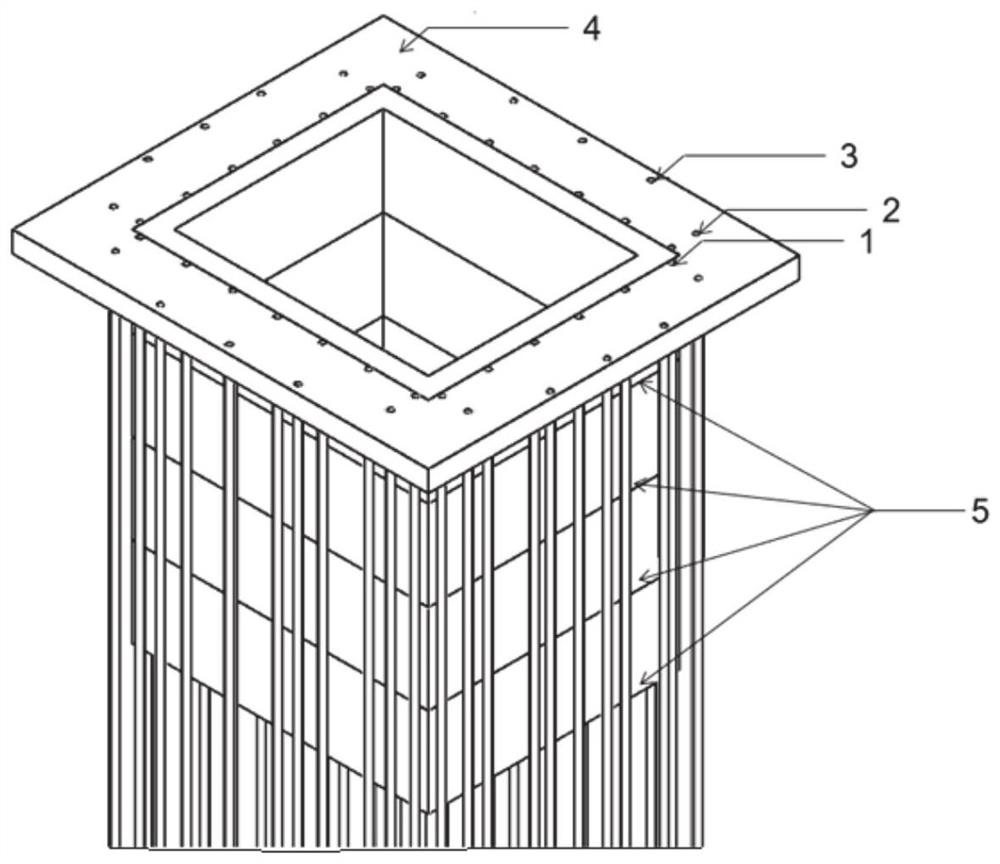

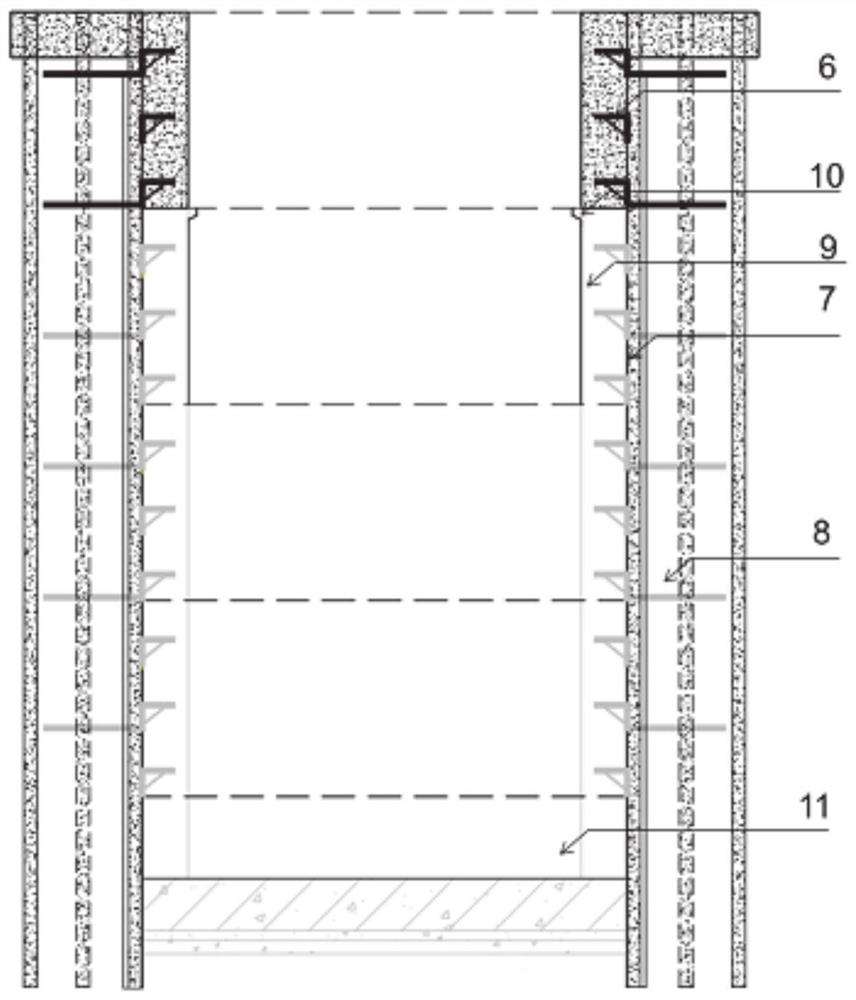

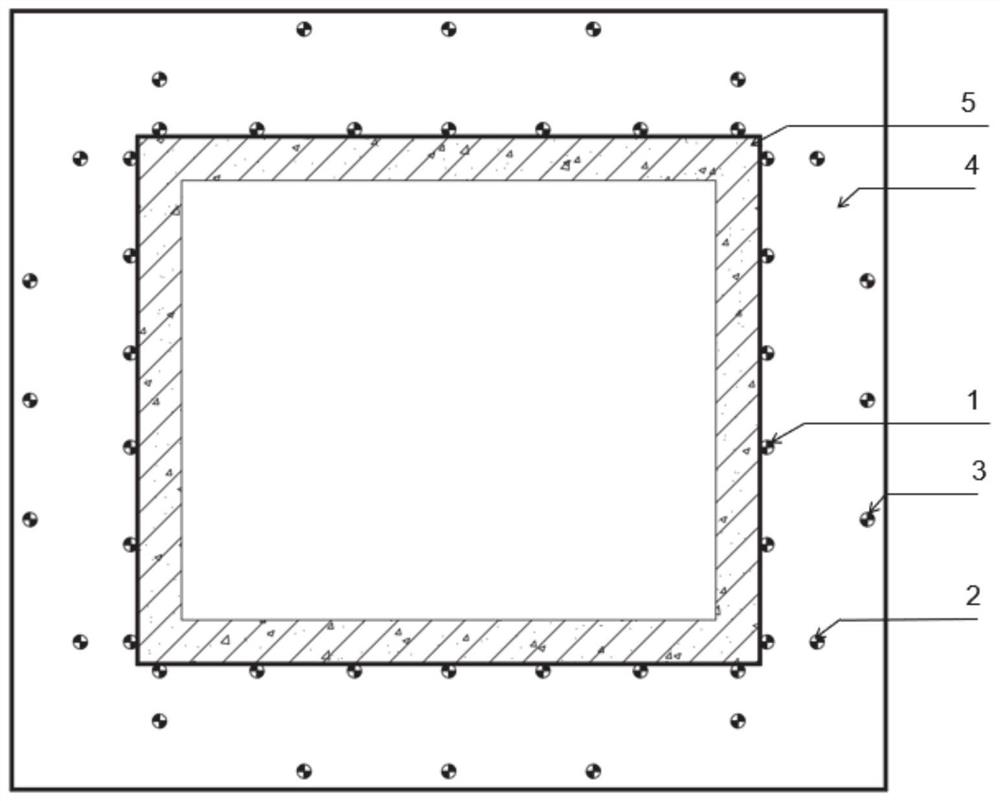

[0055] In a typical embodiment of the present invention, refer to figure 1 As shown in the figure, a support structure for a suspended reverse wall working well includes a well wall 5. The well wall consists of multiple sections from top to bottom, and two adjacent sections of the well wall are connected. 4. The top plate 4 is connected to the well wall 5 to form a suspended well wall, and the top plate 4 is used as a lever plate on the top of the well wall to enhance the structural integrity; the top plate 4 is connected to the tops of multiple rows of support piles respectively, and all the support piles It is used as a composite suspension stress system with the top plate to suspend the shaft wall.

[0056] Further, each section of the well wall has a set height, and each section of the well wall is a cast-in-place piece, and two adjacent sections of the well wall are connected through the steel wire mesh and concrete pouring on the inner side of the well wall;

[0057] Th...

Embodiment 2

[0071] Taking a pipe jacking working well as an example, due to the high bearing capacity of the foundation where the project is located, the friction coefficient of the soil is relatively large, and the outer wall of the working well passes through relatively broken limestone, which further increases the friction between the outer wall and the surrounding soil. There are certain risks in the previous caisson construction method. The construction process is as follows:

[0072] ①Measurement and placement of piles, construction of supporting piles→②Excavation of the first section, and laying steel wire mesh→③Binding the well wall and roof reinforcement→④Setting up the formwork, pouring concrete to reach the design strength, and removing the formwork→⑤Opening of the next section Digging and laying steel wire mesh → ⑥ Binding the next section of shaft wall reinforcement → ⑦ Supporting formwork, pouring concrete to reach the design strength, removing the formwork → repeating ⑥ → ⑧...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com