Double-channel heater drain cooling section inlet structure and design method

A technology of hydrophobic cooling and design method, applied in mechanical equipment, machine/engine, steam application, etc., can solve problems such as fluctuation of heater water level, increase of hydrophobic end difference of heater, aggravation of pipe wall, etc., to enhance surface tension and the effects of viscous force, increased suction speed, and improved siphon ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

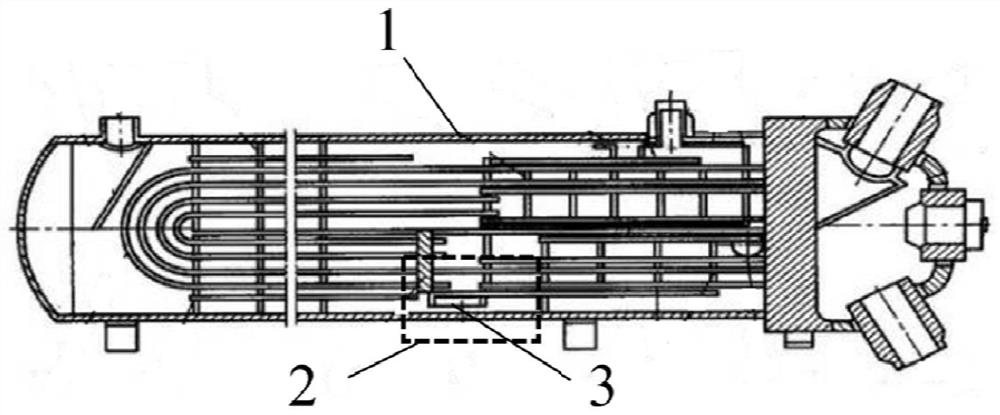

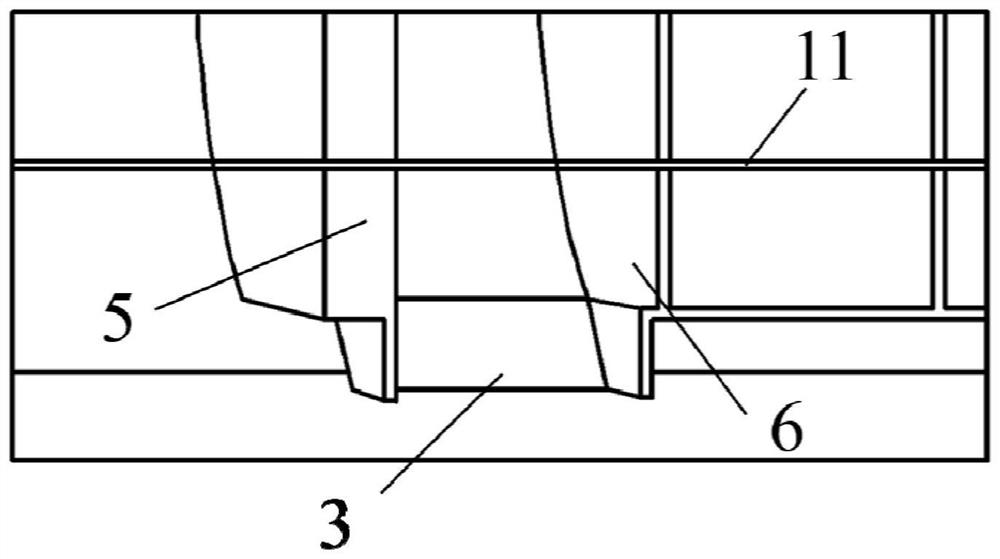

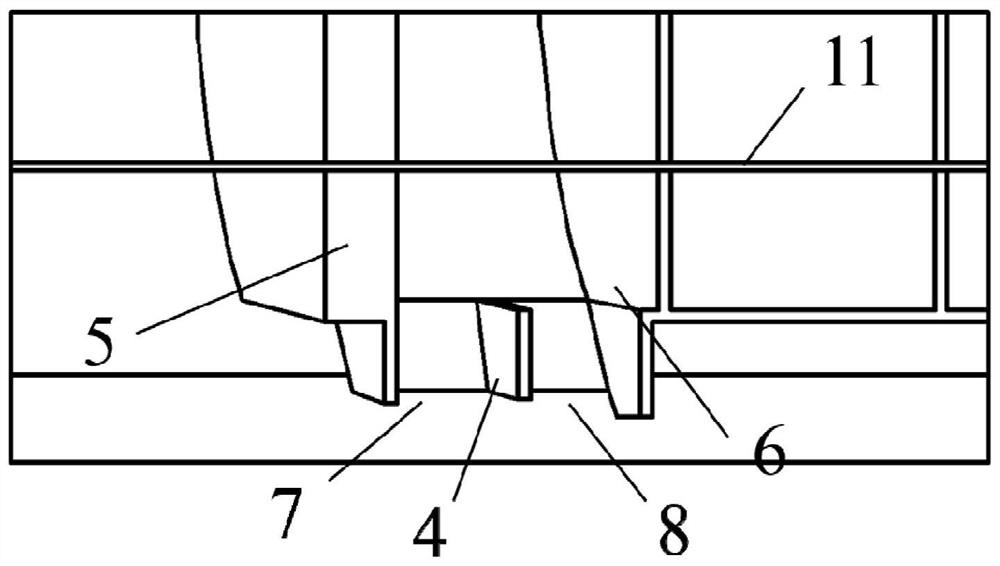

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

[0031] see Figure 1 to Figure 5 , an inlet structure of the hydrophobic cooling section of the dual-channel heater, comprising a hydrophobic cooling end plate 5 on the upstream side of the hydrophobic cooling section of the heater, a hydrophobic cooling end plate 6 on the downstream side of the hydrophobic cooling section of the heater, and a hydrophobic cooling end on the upstream side of the hydrophobic cooling section of the heater Between the plate 5 and the hydrophobic cooling end plate 6 on the downstream side of the heater hydrophobic cooling section is the inlet 3 of the siphon section of the heater hydrophobic cooling section, and the inlet 3 of the siphon section of the heater hydrophobic cooling section is provided with a separating partition 4 for the heater hydrophobic cooling section. The separator 4 of the heater hydrophobic cooling section separates th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com