Adsorption type refrigeration system and operation method thereof

A technology of adsorption refrigeration and operation method, applied in refrigerators, refrigeration components, adsorption machines, etc., can solve problems such as bulky volume and complex system, improve structure compactness, improve adsorption time, and reduce the time of desorption reaction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

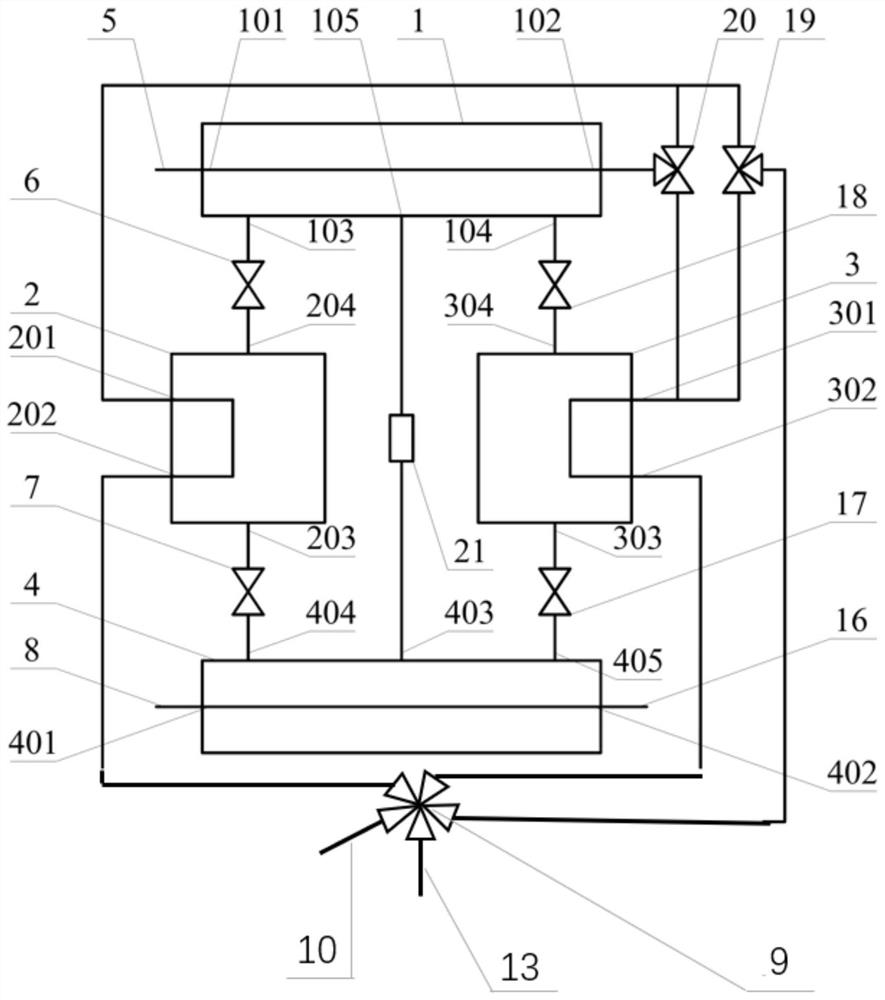

Embodiment 1

[0039] The present invention provides an adsorption refrigeration system, which mainly includes a condenser 1, a first adsorption bed 2, a second adsorption bed 3, an evaporator 4, a throttling device 21, a refrigerant control valve group, a waterway switching valve group, etc. The refrigerant control valve group includes a refrigerant output valve and a refrigerant input valve, and the waterway switching valve group includes a heating fluid switching valve 19 , a cooling fluid switching valve 20 and a first communication valve 9 . The refrigerant output valve and the refrigerant input valve are preferably four two-way control valves, wherein the refrigerant output valve includes a first refrigerant output valve 6 and a second refrigerant output valve 18, and the refrigerant input valve includes a first refrigerant output valve 6 and a second refrigerant output valve 18. input valve 7 and the second refrigerant input valve 17 .

[0040] The first communication valve 9 is used ...

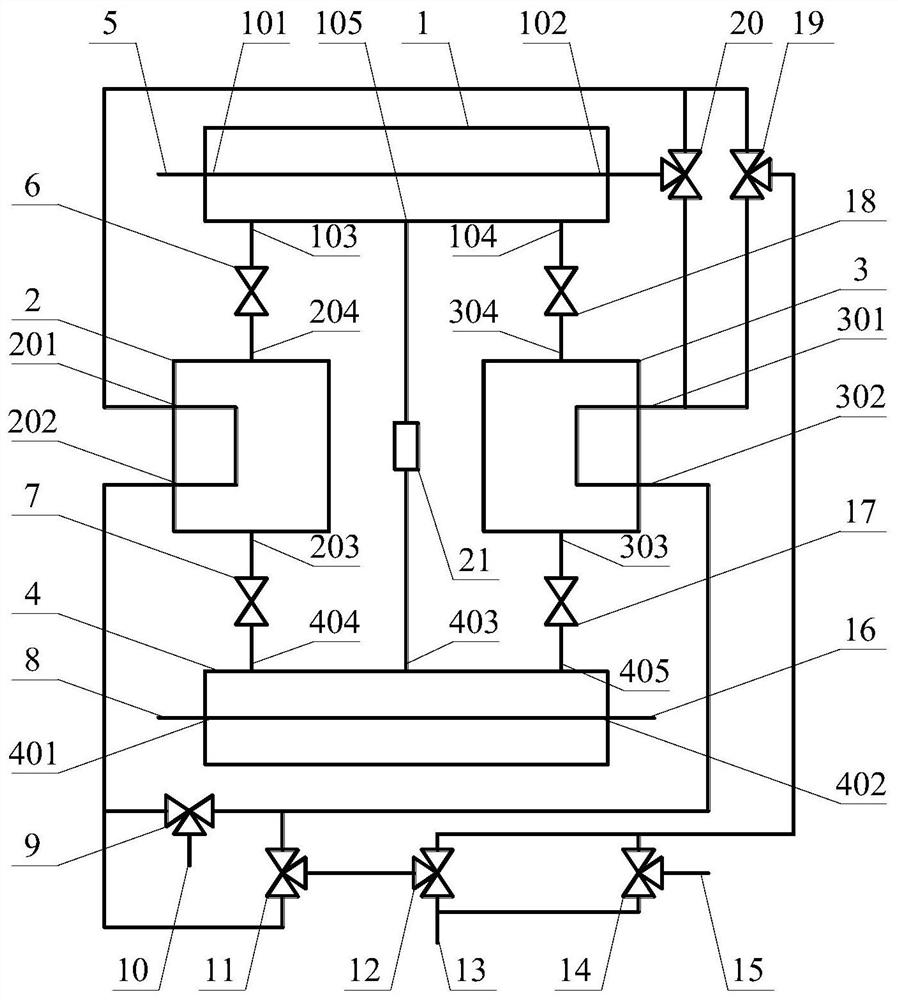

Embodiment 2

[0056] This embodiment 2 is formed on the basis of embodiment 1. By optimizing the setting of the water circuit switching valve group and adding the control valve of the heating pipeline, the entry and exit of cold and hot fluids are controlled by independent valves, which improves the stability of the system operation. sex. specifically:

[0057] Such as figure 2 As shown, a second communication valve 11, a third communication valve 12 and a fourth communication valve 14 are added to the system. After the second communication valve 11, the third communication valve 12 and the fourth communication valve 14 are connected in sequence, The second communication valve 11 realizes the re-communication between the first adsorption bed 2 and the second adsorption bed 3, so that the second communication valve 11 and the first communication valve 9 form a parallel relationship to improve the stability of the system; on the other hand, through the third The communication valve 12 and ...

Embodiment 3

[0075] Embodiment 3 is formed on the basis of Embodiment 1 or Embodiment 2. By designing double adsorption steps in the operation cycle of the refrigeration system, the adsorption time of the adsorption bed is further increased, the refrigeration efficiency of the refrigeration system is improved, and the structural size is reduced. specifically:

[0076] The adsorption procedure of the first adsorption bed and / or the adsorption procedure of the second adsorption bed also include double adsorption steps, preferably both the adsorption procedure of the first adsorption bed and the adsorption procedure of the second adsorption bed include double adsorption steps. The double adsorption steps are both located after the pre-cooling adsorption step. The circulation path of the hot and cold fluids in the double adsorption step is the same as that in the pre-cooling adsorption step, the main difference is that the opening states of the valves of the refrigerant control valve group are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com