Wearable flexible sensor and preparation method thereof

A flexible sensor and flexible technology, applied in instruments, measuring devices, fluid pressure measurement by changing ohmic resistance, etc., can solve the problems of linearity influence and limit sensor, etc., achieve various structural forms, high sensitivity and linearity, and improve Effect of Surface Roughness and Conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

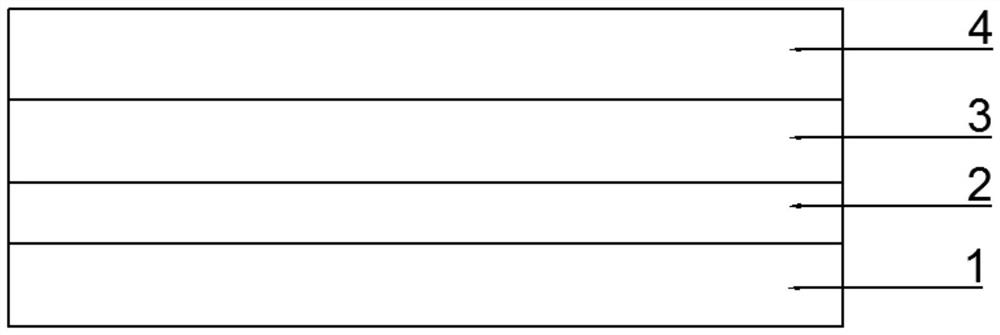

[0036] A preparation method of a wearable flexible sensor, comprising the following preparation steps:

[0037] S1: Clean the non-woven cotton and dry it in an oven, print conductive silver paste on the non-woven cotton by screen printing process, put it into the oven for drying (70°C, 1h), and obtain a flexible substrate with electrodes.

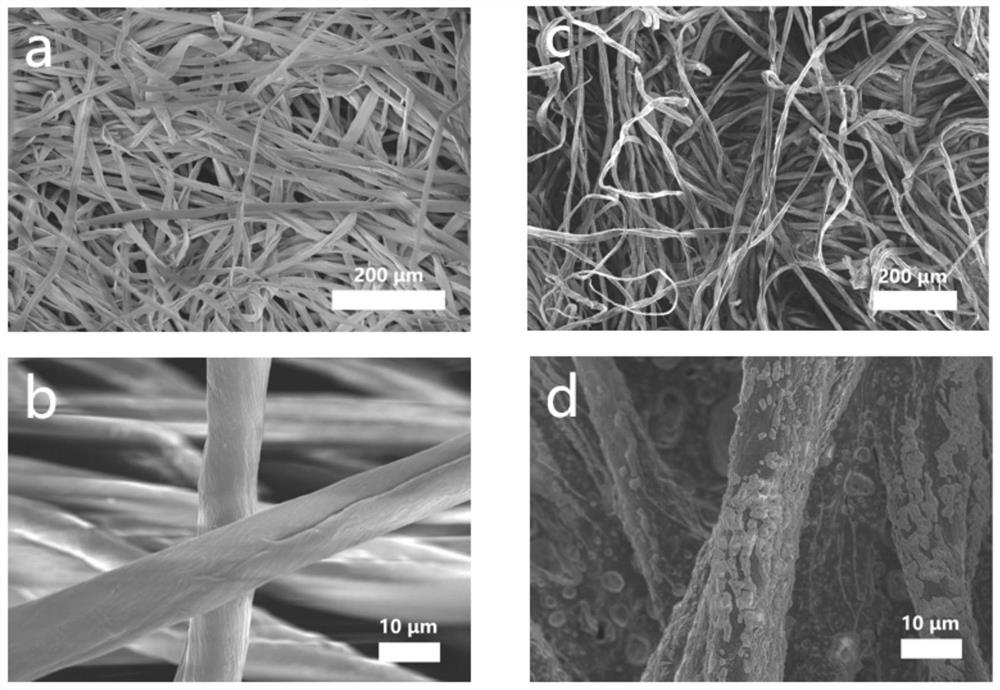

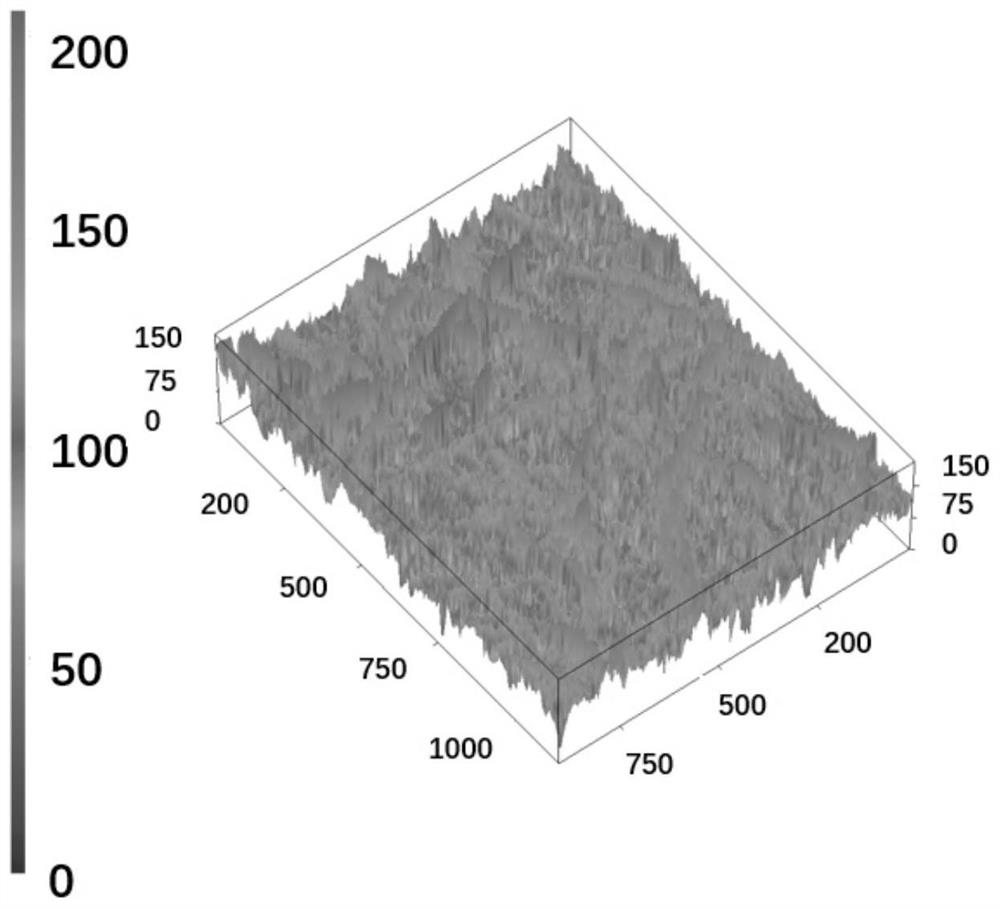

[0038] S2: Another non-woven cotton is taken, and the PEDOT polymer formed by gas-phase polymerization on its surface is cleaned and dried to obtain a piezoresistive layer; specifically:

[0039] S21: washing the non-woven cotton with ethanol and deionized water and drying;

[0040] S22: Add 1mol / L FeCl 3 .6H 2 O as an oxidizing agent was dissolved in isopropanol by ultrasonic waves for 15 minutes, and then dripped and infiltrated onto non-woven cotton to obtain permeated FeCl 3 The flexible bottom plate;

[0041] S23: will be infiltrated with FeCl 3 Put the flexible bottom plate and EDOT solution into a vacuum container for gas-phase ...

Embodiment 2

[0049] A preparation method of a wearable flexible sensor, comprising the following preparation steps:

[0050] S1: Clean the non-woven cotton and dry it in an oven, print conductive silver paste on the non-woven cotton by screen printing process, put it into the oven for drying (70°C, 1h), and obtain a flexible substrate with electrodes.

[0051] S2: Another non-woven cotton is taken, and the PEDOT polymer formed by gas-phase polymerization on its surface is cleaned and dried to obtain a piezoresistive layer; specifically:

[0052] S21: washing the non-woven cotton with ethanol and deionized water and drying;

[0053] S22: 0.8mol / L FeCl 3 .6H 2 O as an oxidizing agent was dissolved in isopropanol by ultrasonic waves for 15 minutes, and then dripped and infiltrated onto non-woven cotton to obtain permeated FeCl 3 The flexible bottom plate;

[0054] S23: will be infiltrated with FeCl 3 Put the flexible bottom plate and EDOT solution into a vacuum container for gas-phase po...

Embodiment 3

[0059] A preparation method of a wearable flexible sensor, comprising the following preparation steps:

[0060] S1: Clean the non-woven cotton and dry it in an oven, print conductive silver paste on the non-woven cotton by screen printing process, put it into the oven for drying (70°C, 1h), and obtain a flexible substrate with electrodes.

[0061] S2: Another non-woven cotton is taken, and the PEDOT polymer formed by gas-phase polymerization on its surface is cleaned and dried to obtain a piezoresistive layer; specifically:

[0062] S21: washing the non-woven cotton with ethanol and deionized water and drying;

[0063] S22: 0.5mol / L FeCl 3 .6H 2 O as an oxidizing agent was dissolved in isopropanol by ultrasonic waves for 15 minutes, and then dripped and infiltrated onto non-woven cotton to obtain permeated FeCl 3 The flexible bottom plate;

[0064] S23: will be infiltrated with FeCl 3 Put the flexible bottom plate and EDOT solution into a vacuum container for gas-phase po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com