On-line Suppression Method of Rotor Position Offset Error of Permanent Magnet Synchronous Motor

A permanent magnet synchronous motor and rotor position technology, which is applied in motor control, motor generator control, AC motor control, etc., can solve problems such as low signal-to-noise ratio, current amplitude fluctuation, etc., achieve high versatility, and improve engineering practicality The effect of avoiding low signal-to-noise ratio and large current amplitude fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

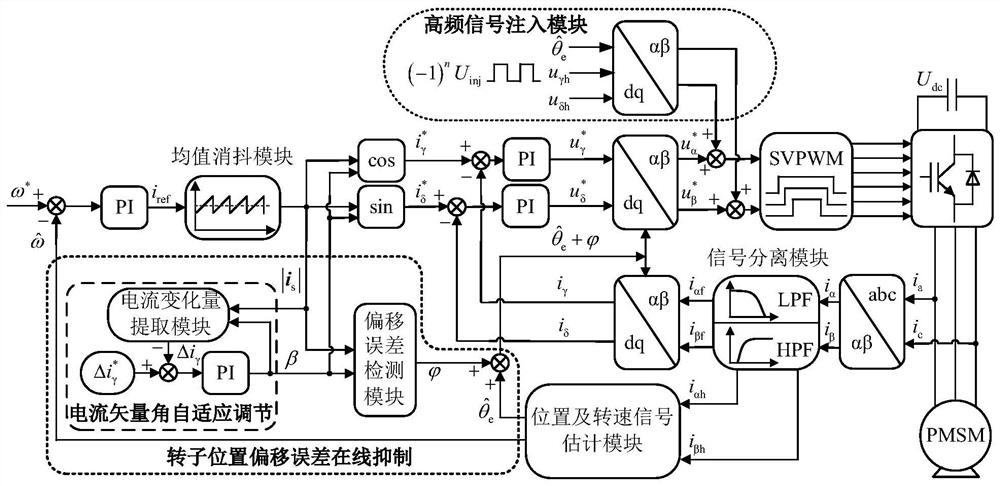

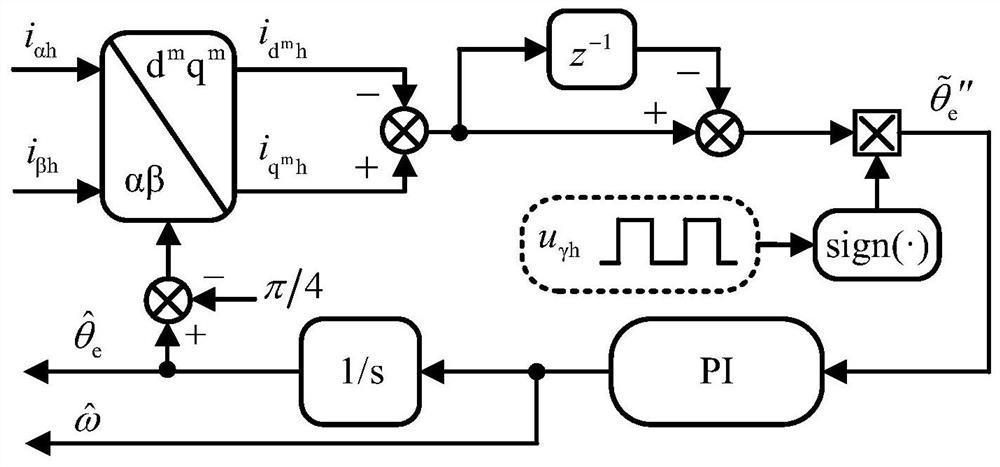

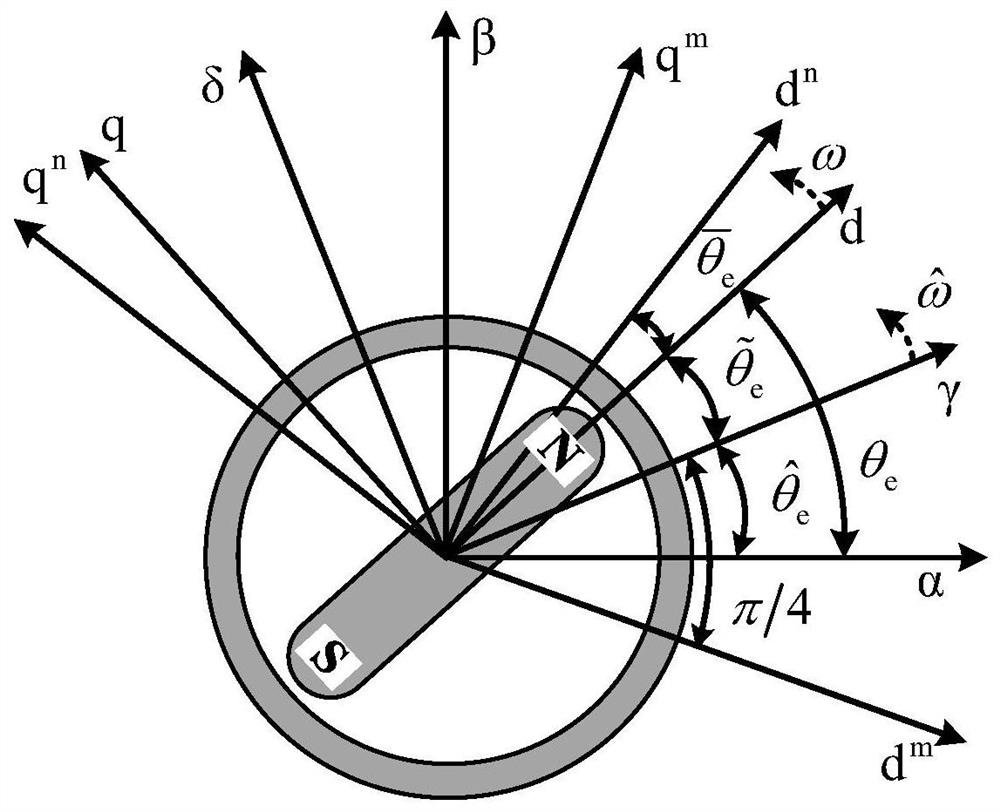

[0064] Specific implementation mode 1. Combination Figure 1 to Figure 3 As shown, the present invention provides an online method for suppressing the rotor position offset error of a permanent magnet synchronous motor, including:

[0065] The high-frequency square wave voltage signal is injected into the γ-δ shaft system, and the original rotor position estimate is obtained by identifying the high-frequency mathematical model of the permanent magnet synchronous motor established under the γ-δ shaft system;

[0066] Based on the electromagnetic torque equation of the motor, the rotor position offset error existing in the original rotor position estimation value is calculated and obtained by using the two current vector amplitudes and their corresponding current vector angles that can be adaptively adjusted according to the load conditions at adjacent moments. ;The two current vector angles can be adjusted adaptively according to the load conditions, so as to effectively avoid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com