Direct reduction shaft furnace with probe for interior gas analysis

A gas analysis system and probe technology, used in the internal sensor of the direct reduction shaft furnace, the field of the direct reduction shaft furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

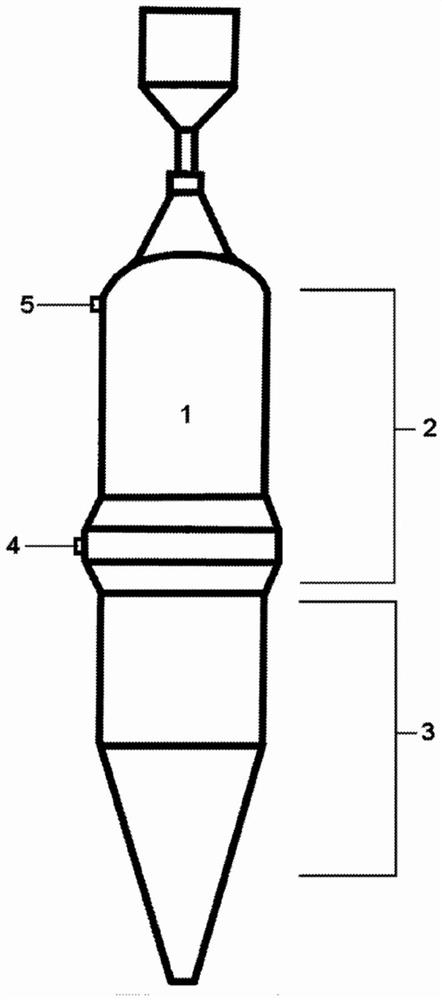

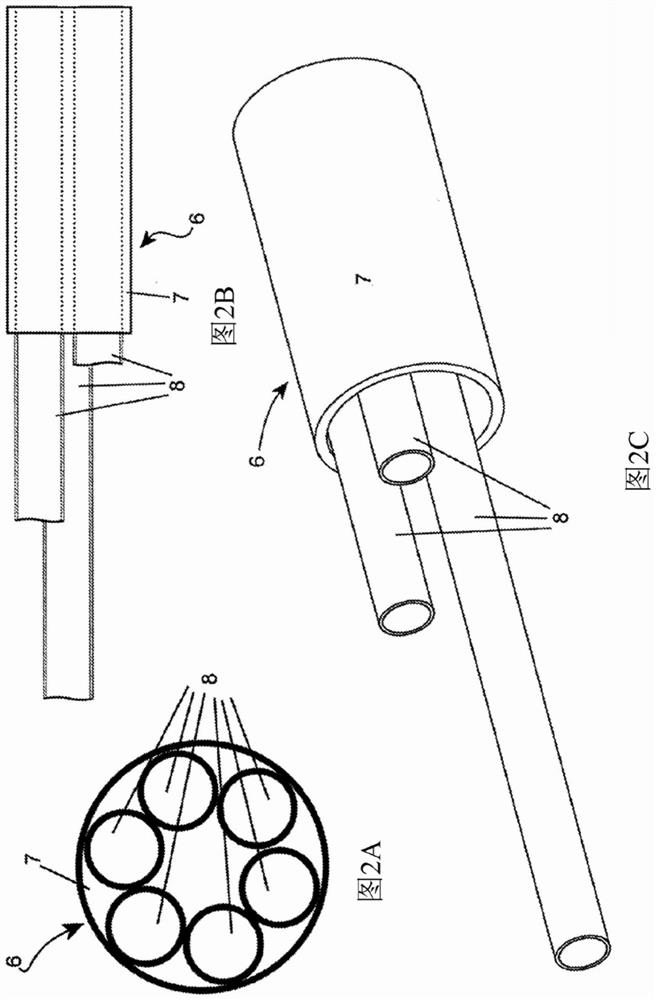

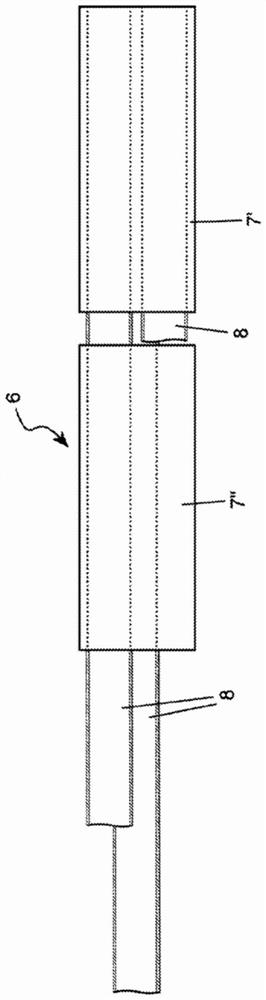

[0026] The invention relates to a DR shaft furnace with at least one probe arranged vertically in its reduction zone. The probes preferably extend from the top to the bottom of the reducing zone. The probe allows gas sampling along its length and delivery of the gas to at least one type of gas analysis device and pressure measurement instrumentation. The probe may also allow the temperature of the gas sample to be measured as the gas sample is taken. Thus, the DR furnace and probe combination of the present invention allows gas samples and temperatures to be taken at different levels inside the furnace. Probes may be mounted vertically along the diameter of the DR shaft at one or more locations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com