Drill bit grinding machine

A grinding machine and drill bit technology, which is applied to the parts of grinding machine tools, grinding machines, drilling tool accessories, etc., can solve the problems of not being suitable for small processing operations, poor control of grinding accuracy, high production costs, etc., and achieve a wide range of applications , improve grinding efficiency, and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

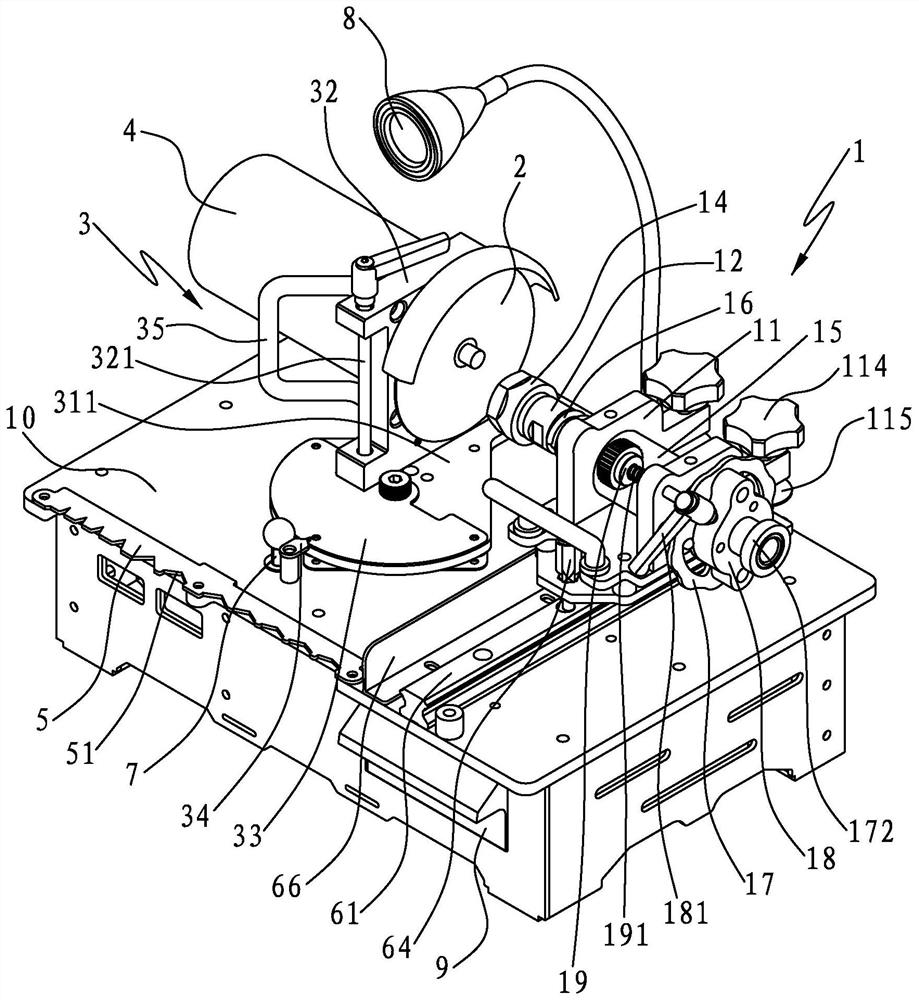

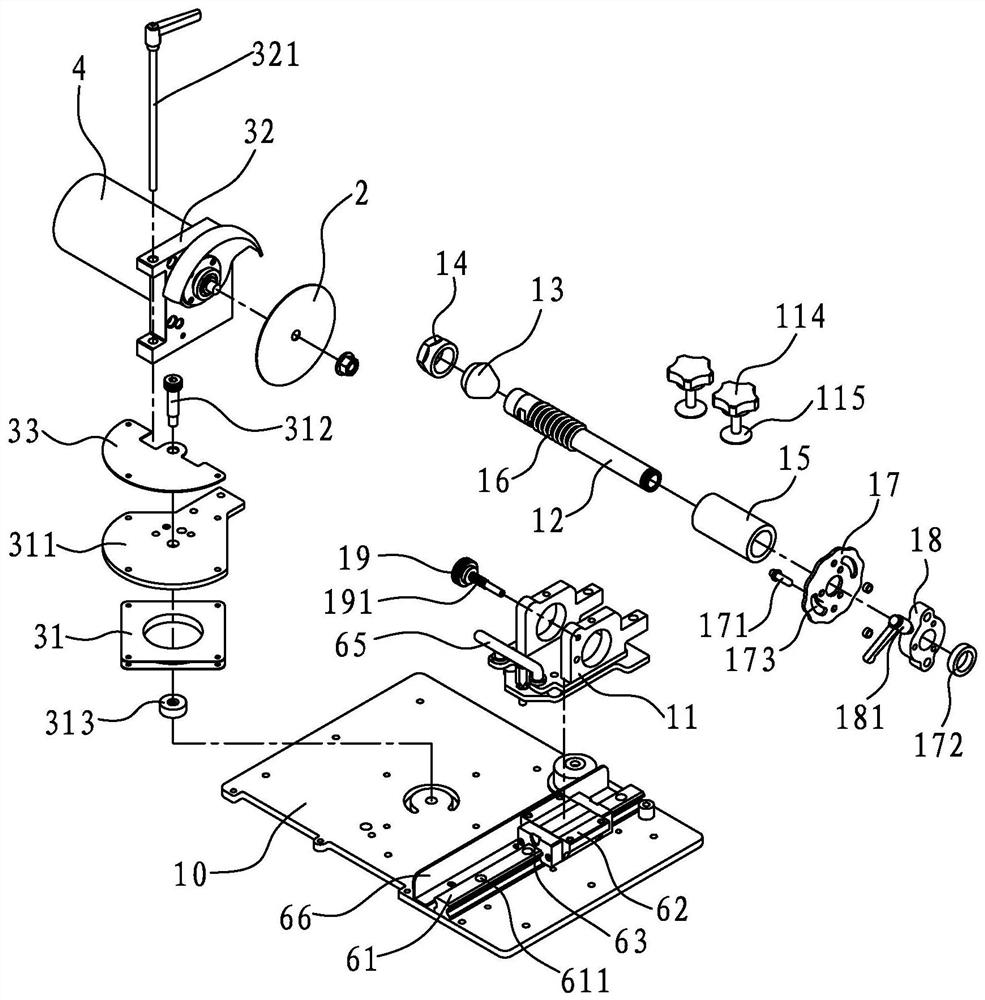

[0066] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

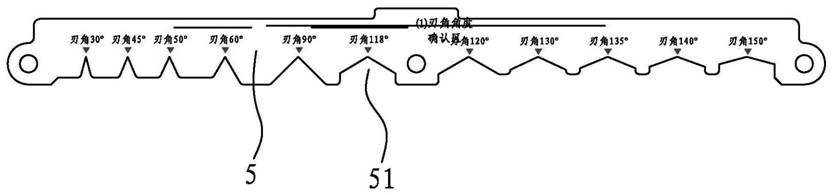

[0067] see Figure 1 to Figure 14 , the present invention discloses a drill grinder, including a workbench 10 and a drill rod collet 1, a grinding wheel 2, a grinding wheel seat 3 and a motor 4 arranged on the workbench 10;

[0068] The drill rod collet 1 has a fixed seat 11 and a drill rod sleeve 12, a spring collet 13, a lock nut 14 at the front end of the sleeve, a ball sleeve 15 and a drill rod sleeve spring 16 arranged on the fixed seat 11; The fixed seat 11 has two supporting vertical plates 111 on which the ball sleeve 15 is erected, the drill rod sleeve 12 is installed on the ball sleeve 15 and the front and rear ends protrude from the two supporting vertical plates 111 respectively; The clamp 13 is assembled inside the front end of the drill rod sleeve 12, and the lock nut 14 at the front end of the s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap