Preparation method of polytetrafluoroethylene film with ultrahigh air permeability

A technology of polytetrafluoroethylene and air permeability, which is applied in the field of preparation of polytetrafluoroethylene films to achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

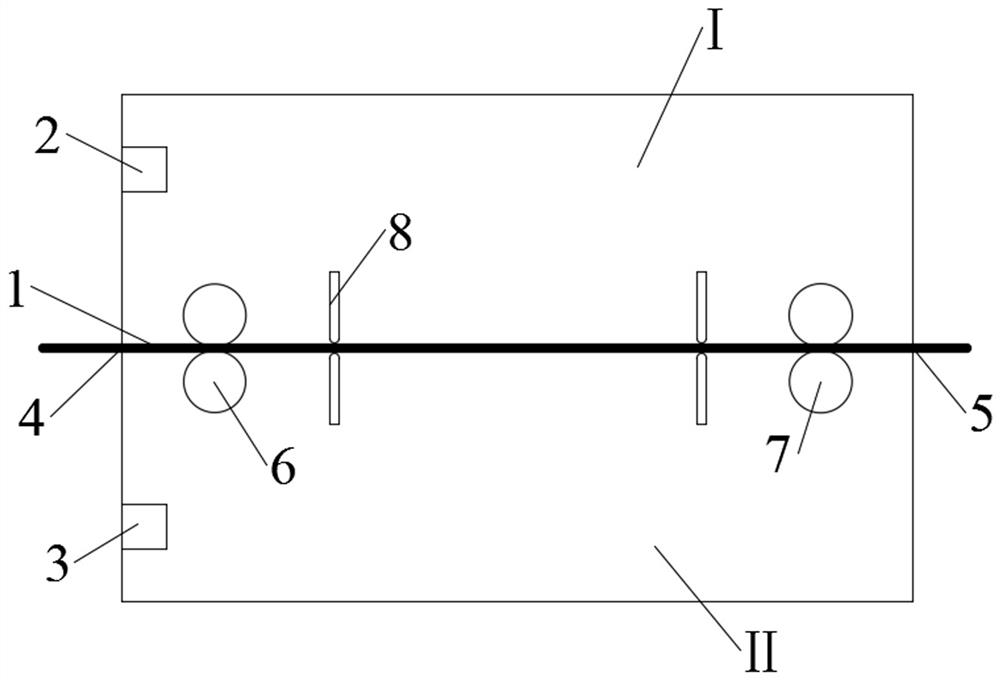

[0039] The schematic diagram of the asymmetrical heating oven of the present invention is as figure 1 shown by figure 1As shown, the asymmetric heating oven includes an upper heat-setting heating zone I and a lower heat-setting heating zone II arranged on both sides 1 of the biaxially stretched base film, which are used to blow heat into the asymmetric heating oven. The upper tuyere 2 and the lower tuyeres 3 that enter the hot air, the first clamping device 6 and the second clamping device 7 that are respectively arranged at the film inlet 4 and the film outlet 5, and symmetrically arranged on the two-way stretching base Temperature probes on both sides of the membrane8.

[0040] The temperature probe point 8 is set between the first clamping device and the second clamping device, and the temperature probe point is close to the first clamping device or the second clamping device The distance between the temperature probes is 15 cm, the distance between the temperature probe ...

Embodiment 2

[0053] The distance between the temperature probe point and the first clamping device or the second clamping device is 16 cm, and the distance between the temperature probe point and the surface of the biaxially stretched base film is 3.3 mm , the number of temperature probe points is 4.

[0054] The upper tuyeres and the lower tuyeres are respectively arranged in the upper heat-setting heating zone and the lower heat-setting heating zone, and the upper tuyeres and the lower tuyeres are connected with the biaxially stretched base film. The distance between the two sides is 8cm.

[0055] A preparation method of a polytetrafluoroethylene film with ultra-high air permeability, comprising the steps of:

[0056] S1 compounding: polytetrafluoroethylene dispersion resin and extrusion aid are carried out raw material mixing; In the present embodiment, extrusion aid is preferably kerosene, and consumption is 20% of polytetrafluoroethylene dispersion resin quality, and polytetrafluoroe...

Embodiment 3

[0066] The distance between the temperature probe point and the first clamping device or the second clamping device is 15 cm, and the distance between the temperature probe point and the surface of the biaxially stretched base film is 3 mm , the number of temperature probe points is 6.

[0067] The upper tuyeres and the lower tuyeres are respectively arranged in the upper heat-setting heating zone and the lower heat-setting heating zone, and the upper tuyeres and the lower tuyeres are connected with the biaxially stretched base film. The distance between the two sides is 10cm.

[0068] A preparation method of a polytetrafluoroethylene film with ultra-high air permeability, comprising the steps of:

[0069] S1 compounding: polytetrafluoroethylene dispersion resin and extrusion aid are carried out raw material mixing; In the present embodiment, extrusion aid is preferably kerosene, and consumption is 30% of polytetrafluoroethylene dispersion resin quality, polytetrafluoroethyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com