Inverted adsorption precipitation system and process based on classified recovery of carbon sources

A technology for adsorption, precipitation and carbon source, applied in sedimentation treatment, water/sewage multi-stage treatment, filtration treatment, etc., can solve problems such as low carbon source recovery rate and carbon source loss, and achieve improved carbon source recovery rate and reduced operation Cost, the effect of reducing aeration energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

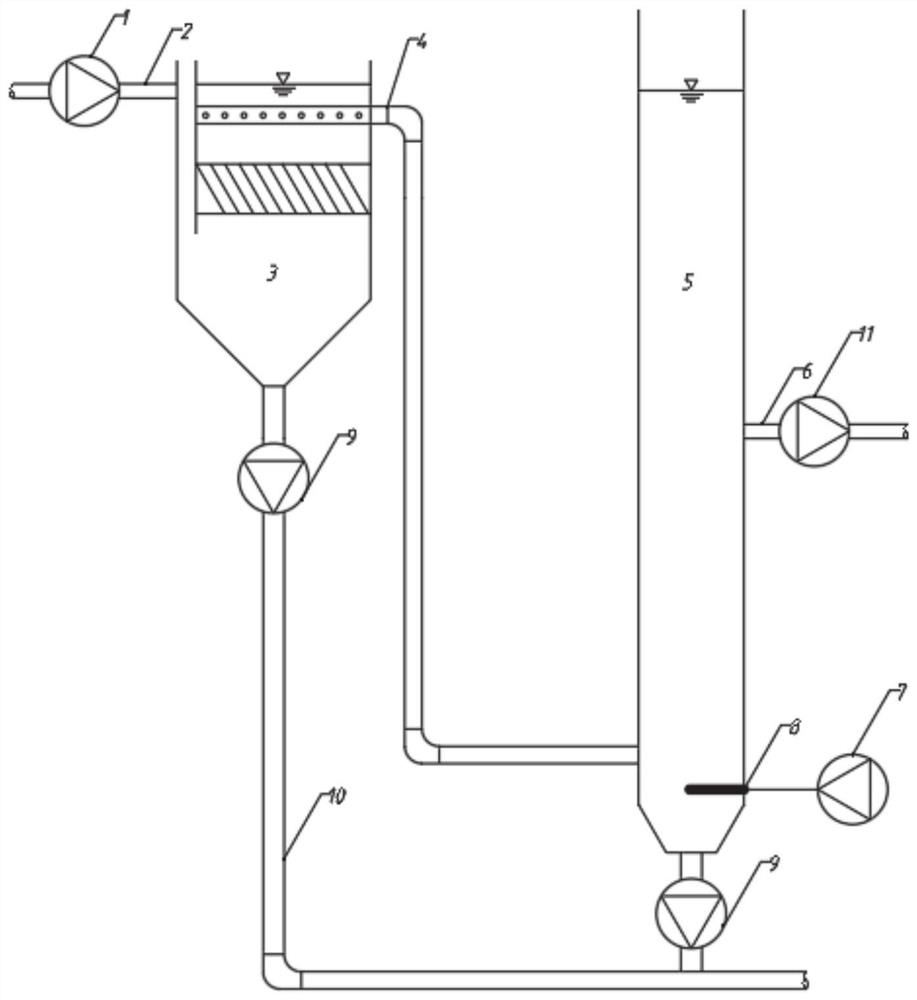

[0057] like figure 1 As shown, an inverted adsorption sedimentation process based on classified recovery of carbon sources, the device mainly includes water inlet pump 1, first water inlet pipe 2, inclined plate sedimentation tank 3, perforated overflow pipe 4, post activated sludge adsorption tank 5. Water outlet pipe 6, aeration pump 7, microporous aeration disc 8, sludge pump 9, sludge pipe 10 and water outlet pump 11.

[0058] The front sedimentation tank adopts inclined plate sedimentation tank 3, and its effective volume is 50% of the effective volume of rear activated sludge adsorption tank 5, the inclined plate is inclined at 60°, the distance between inclined plates is 4 cm, and the volume of mud bucket is about 20% of the volume of sedimentation tank 3. The effective volume of the rear activated sludge adsorption tank 5 is twice the effective volume of the inclined plate sedimentation tank 3, and the diameter-depth ratio of the activated sludge adsorption tank 5 is ...

Embodiment 2

[0061] An inverted adsorption-sedimentation process based on the classification and recovery of carbon sources, intermittent operation, a cycle lasts 65 minutes: the pre-sloping plate sedimentation tank is filled with water for 20 minutes, idle for 45 minutes, the post-activated sludge adsorption tank is filled with water + aeration for 20 minutes, and sedimented for 20 minutes , out of water for 20 minutes, and idle for 5 minutes. In the water intake stage, the sewage first enters the inclined plate sedimentation tank to enrich and recover the carbon source that is easy to precipitate in the sewage. The effluent of the inclined plate sedimentation tank enters the activated sludge adsorption tank, where it is mixed with the sludge and aerated at the same time. The DO is controlled at 0.5-1mg / L, to promote the activated sludge to absorb carbon sources that are not easy to settle in the sewage; in the sedimentation stage, the mud level of the adsorption tank will drop by more th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com