Autoclaved sand-lime brick and preparation method thereof

A technology of autoclaved lime-sand brick and quicklime, which is applied in the field of building materials, can solve the problems of unstable shrinkage and easy cracking, and achieve the effects of shortening maintenance time, avoiding cracking, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

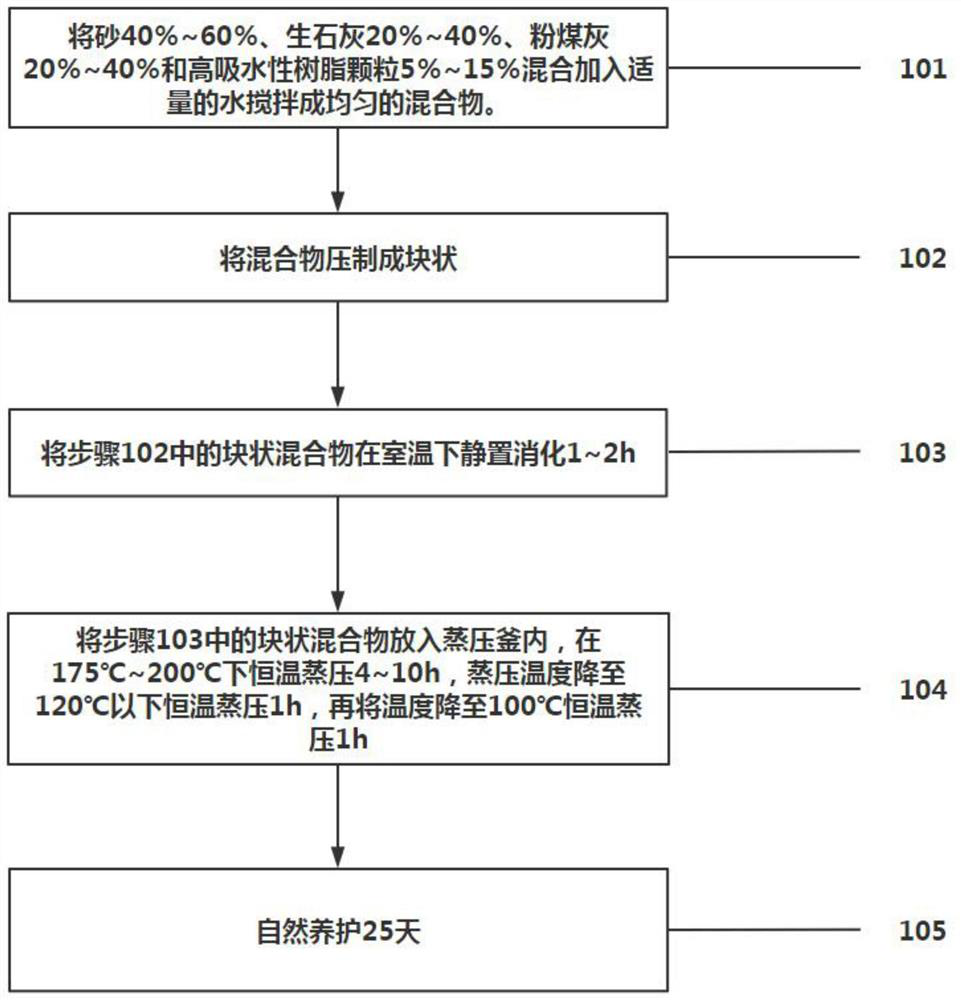

[0045] For ease of understanding, see figure 1 , The application provides an embodiment of an autoclaved lime-sand brick. According to mass percentage, the raw materials of the autoclaved lime-sand brick include: 40% to 60% of sand, 20% to 40% of quicklime, and 20% to 40% of fly ash % and superabsorbent resin particles 5% to 15%;

[0046] The autoclaved lime-sand brick is prepared by the following preparation method, including the following steps:

[0047] Step 101, mix 40%-60% of sand, 20%-40% of quicklime, 20%-40% of fly ash and 5%-15% of superabsorbent resin particles, add appropriate amount of water and stir to form a uniform mixture.

[0048] It should be noted that a small amount of chemical binder can be added to the raw materials of autoclaved lime-sand bricks to improve the coagulation of raw materials after mixing. Combine chemical binder, 40%-60% of sand, 20%-40% of quicklime, 20%-40% of fly ash and 5%-15% of superabsorbent resin particles, add appropriate amount ...

Embodiment 2

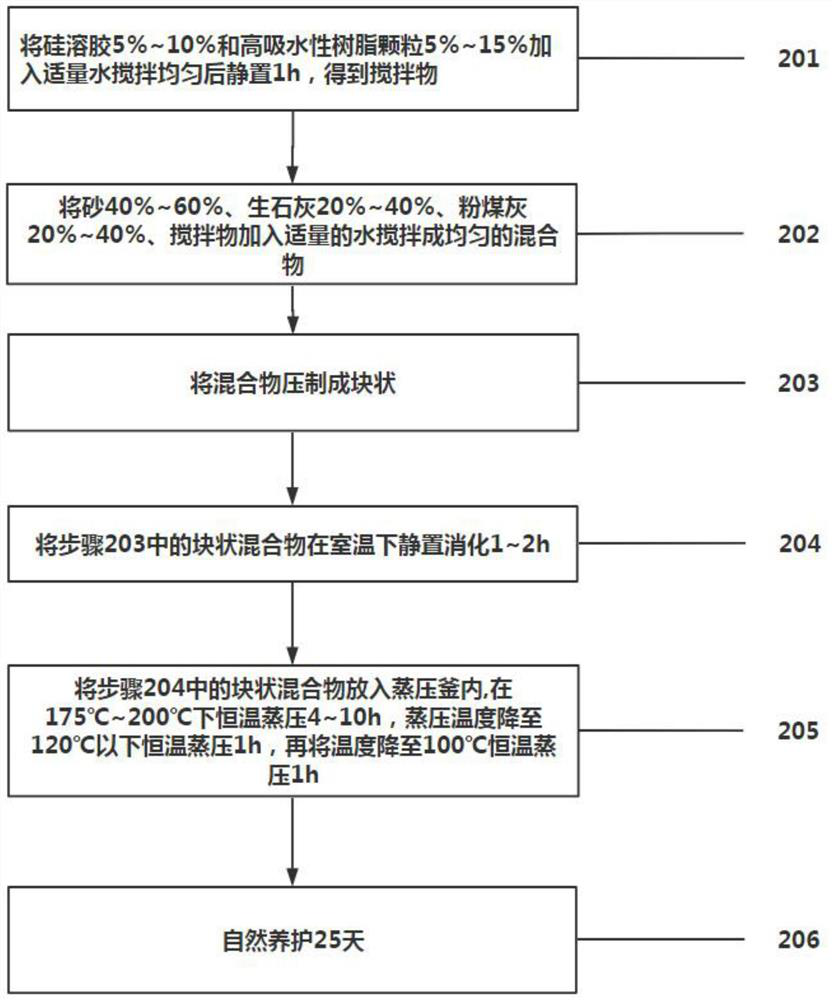

[0059] As a further improvement of Implementation 1, such as figure 2 As shown, the raw material of an autoclaved lime-sand brick provided in this embodiment also includes 5% to 10% of silica sol;

[0060] The autoclaved lime-sand brick is prepared by the following preparation method, including the following steps:

[0061] Step 201, adding 5%-10% of silica sol and 5%-15% of superabsorbent resin particles into an appropriate amount of water, stirring evenly, and then standing still for 1 hour to obtain a stirred product.

[0062] It should be noted that the blending and compounding of superabsorbent resin and inorganic substances is beneficial to improve the strength of the water-absorbing agent. In this embodiment, it is preferred that the superabsorbent resin is polypropylene amine, and the inorganic substance is silica sol. After the two are blended and polymerized, the strength of the superabsorbent resin can be improved, and the strength of the autoclaved lime-sand bric...

Embodiment 3

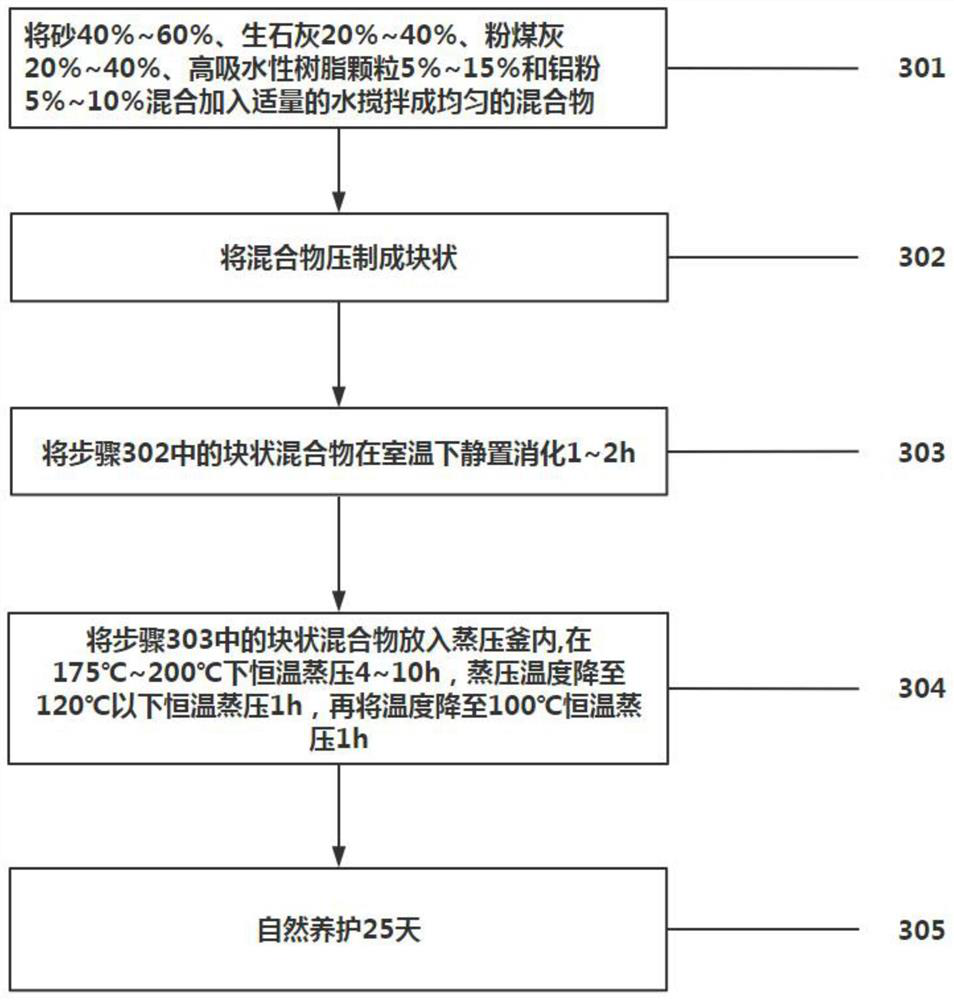

[0074] As a further improvement of embodiment 1 or 2, such as image 3 As shown, the raw material of an autoclaved lime-sand brick provided in this embodiment also includes 5% to 10% of aluminum powder;

[0075] The autoclaved lime-sand brick is prepared by the following preparation method, including the following steps:

[0076] Step 301, mix 40%-60% of sand, 20%-40% of quicklime, 20%-40% of fly ash, 5%-15% of superabsorbent resin particles and 5%-10% of aluminum powder and add appropriate amount of water Stir into a homogeneous mixture.

[0077] It should be noted that a small amount of chemical binder can be added to the raw materials of autoclaved lime-sand bricks to improve the coagulation of raw materials after mixing. Mix chemical binder, 40%-60% of sand, 20%-40% of quicklime, 20%-40% of fly ash, 5%-15% of superabsorbent resin particles and 5%-10% of aluminum powder, and add an appropriate amount The water is stirred into a uniform mixture to facilitate the uniform d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com