Low-temperature lithium iron phosphate and its preparation method and application

A lithium iron phosphate, low temperature technology, applied in positive electrodes, active material electrodes, structural parts, etc., can solve problems such as poor low temperature performance, and achieve the effects of improving ionic conductivity, reducing side reactions, and reducing interface polarization effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

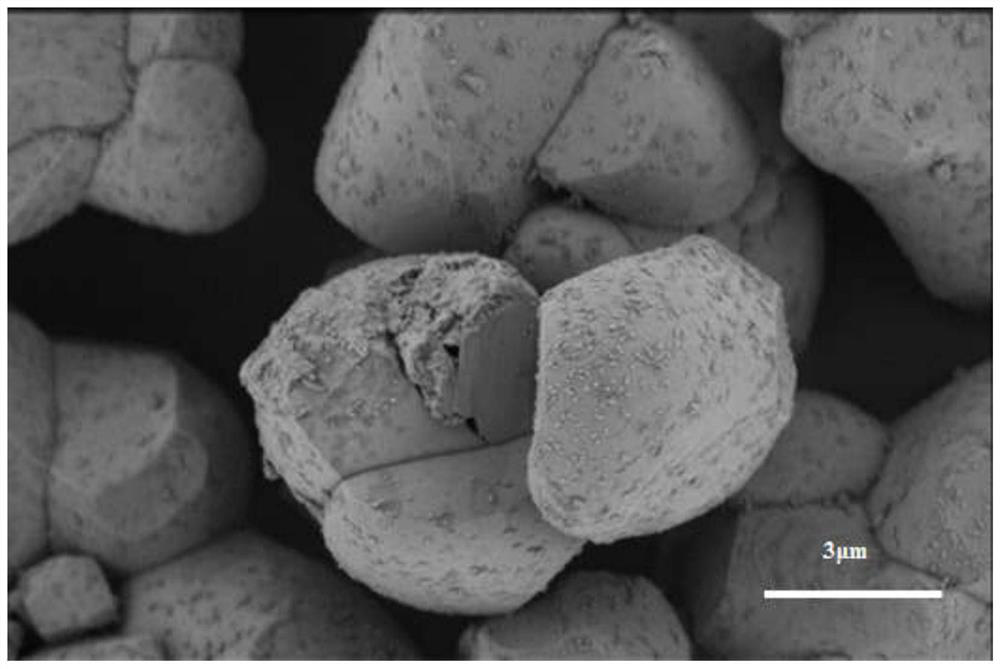

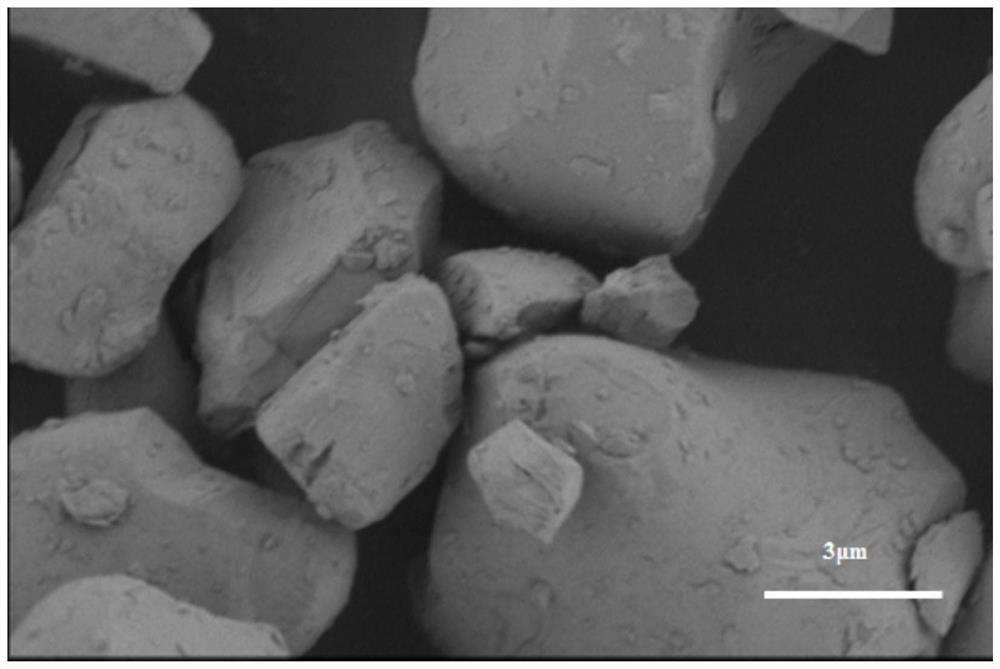

Image

Examples

Embodiment 1

[0038] This embodiment provides a method for preparing low-temperature lithium iron phosphate, comprising the following steps:

[0039] S1. Preparation of CuInS 2 Layer-coated lithium iron phosphate film; ball mill the lithium iron phosphate powder material at a speed of 3000-3500r / min for 20h-22h, add it to deionized water, and add non-ionic dispersant Tween-80 at the same time, in a water bath at 40°C After stirring for 8 hours, a lithium iron phosphate dispersion was obtained, and the Tween-80 mass proportion in the lithium iron phosphate dispersion was 5%.

[0040] 1.5gCu 2 SO 4 ·5H 2 O, 2.5gIn(NO 3 ) 3 4.5H 2 O and 1gCH 3 CSNH 2 (Thioacetamide) was uniformly mixed in 14g deionized water to obtain a mixed solution. This mixed solution was mixed with a lithium iron phosphate dispersion to obtain a slurry.

[0041] The slurry is printed and sprayed onto a single crystal silicon substrate to obtain a wet film of 0.4 μm-0.5 μm, and dried at 100° C. to obtain a precur...

Embodiment 2

[0047] This embodiment provides a method for preparing low-temperature lithium iron phosphate, comprising the following steps:

[0048] S1. Preparation of CuInS 2 Layer-coated lithium iron phosphate film; ball mill the lithium iron phosphate powder material at a speed of 3500r / min for 22h, add it to deionized water, add non-ionic dispersant Tween-80 at the same time, stir in a water bath at 60°C for 10h, and obtain Lithium iron phosphate dispersion liquid, the mass proportion of Tween-80 in the lithium iron phosphate dispersion liquid is 35%.

[0049] 1.5gCu 2 SO 4 ·5H 2 O, 2.5gIn(NO 3 ) 3 4.5H 2 O and 1gCH 3 CSNH 2 Mix evenly with 14 g of deionized water to obtain a mixed solution. This mixed solution was mixed with a lithium iron phosphate dispersion to obtain a slurry.

[0050] The slurry was printed and sprayed onto a single crystal silicon substrate to obtain a 2 μm wet film, and dried at 120° C. to obtain a precursor thin film. Put the precursor film into a se...

Embodiment 3

[0056] This embodiment provides a method for preparing low-temperature lithium iron phosphate, comprising the following steps:

[0057] S1. Preparation of CuInS 2 Layer-coated lithium iron phosphate film; ball mill the lithium iron phosphate powder material at a speed of 3000-3500r / min for 22 hours, add it to deionized water, add non-ionic dispersant Tween-80 at the same time, and stir in a water bath at 40°C for 8 hours , to obtain a lithium iron phosphate dispersion, the mass proportion of Tween-80 in the lithium iron phosphate dispersion is 35%.

[0058] 1.5gCu 2 SO 4 ·5H 2 O, 2.5gIn(NO 3 ) 3 4.5H 2 O and 1gCH 3 CSNH 2 Mix evenly with 14 g of deionized water to obtain a mixed solution. This mixed solution was mixed with a lithium iron phosphate dispersion to obtain a slurry.

[0059]The slurry was printed and sprayed onto a single crystal silicon substrate to obtain a 4 μm wet film, and dried at 120° C. to obtain a precursor thin film. Put the precursor film into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com