Filter press filter plate for ethylene glycol recovery

A filter press filter plate, ethylene glycol technology, applied in the field of filter press filter plate, can solve the problems of poor filter cake block effect, large shock force, deformation of filter press plate, etc., to achieve long service life and improve recovery. The effect of small rate and motion range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

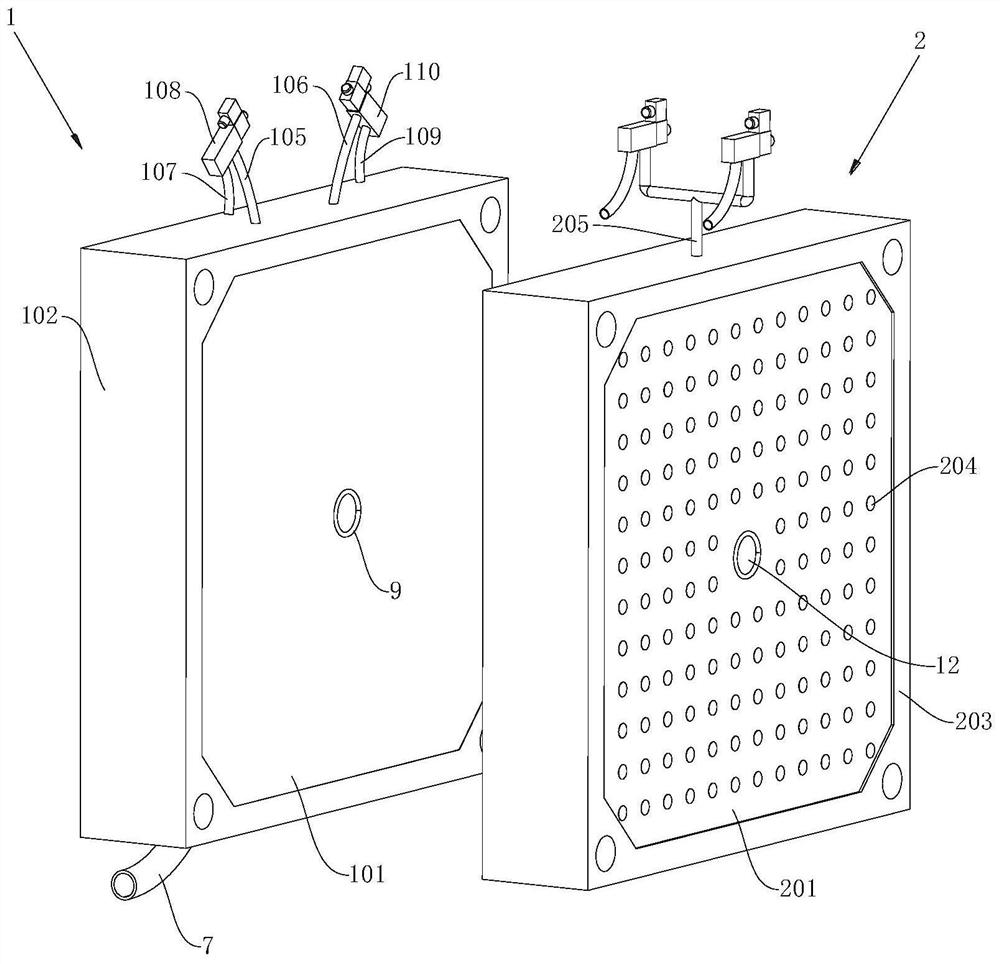

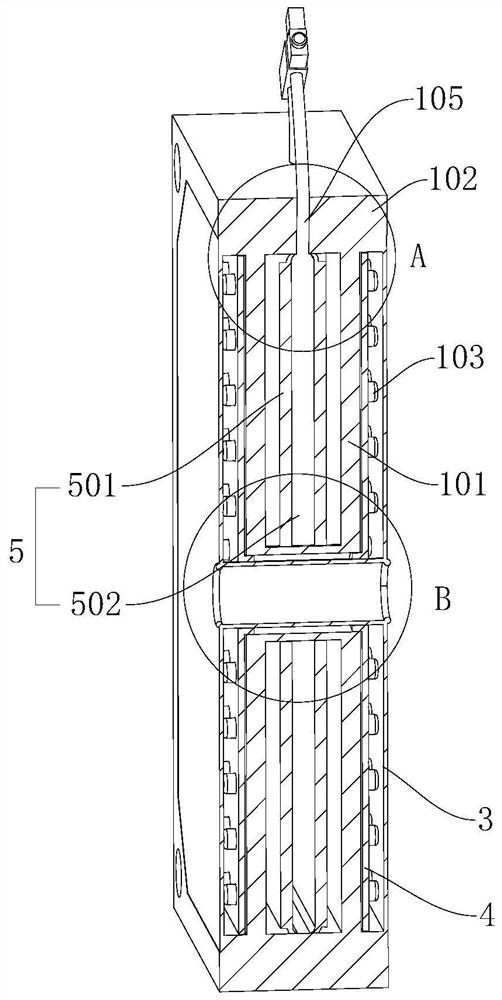

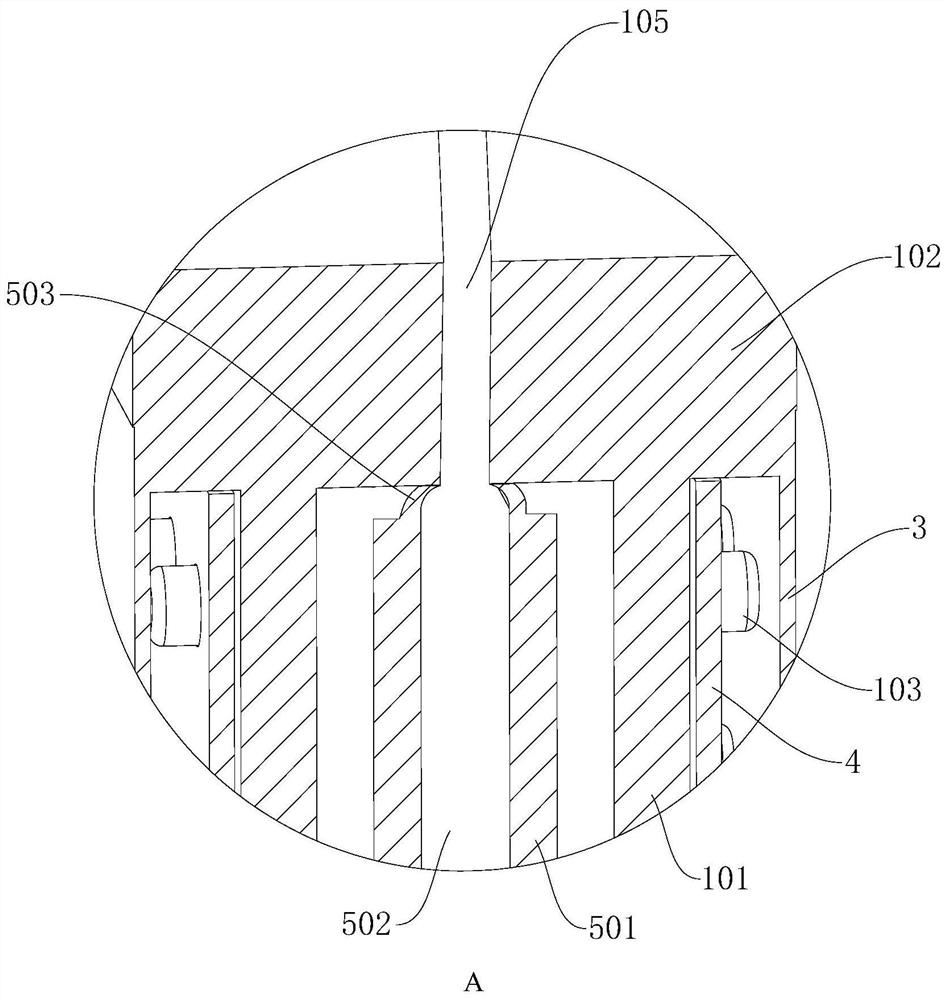

[0033] Example: Filtering plate for ethylene glycol recovery, such as Figure 1-2 As shown, the filter plate 1 and the pressure plate 2, the filter plate 1, and the pressure plate 2 are formed into a group, and when the two are fitted, the filter plate 1 and the pressure plate 2 form a filter chamber. The filter plate 1 includes a filter surface 101, and the filter surface 101 has a sealed edge 102 having a thickness of the filter surface 101, and the filter surface 101 is detachably connected to the filter cloth 3, and the filter surface 101 and the filter cloth 3 are provided. On the plate 4, the push plate 4 slides on the filter plate 1, and a plurality of projections 103 are provided on the filter surface 101, and the push plate 4 is provided with a through hole two embedded in the tape, and the thickness of the push plate 4 is less than convex. The height of 103, the projection 103 can support the filter cloth 3 to support, and the recess between the projections 103 can bring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com