Fabricated building punching equipment

A kind of punching equipment and assembled technology, which is applied in the direction of drilling/drilling equipment, metal processing equipment, boring/drilling, etc., can solve the problems of plate movement and other problems, and achieve the effect of improving processing efficiency and ensuring processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

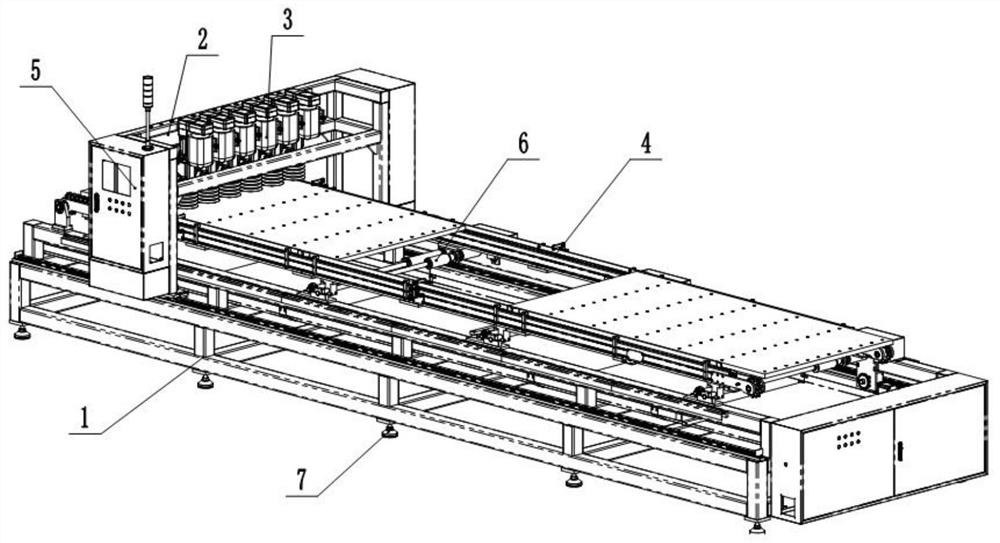

[0020] Basic as attached figure 1 Shown: Prefabricated building drilling equipment, including frame 1, gantry frame 2, walking component, punching component 3, double-speed chain 4 and three electrical cabinets 5; double-speed chain 4 is fixed on frame 1, double-speed chain 4 Width adjustment assembly 6 for adjusting the width of double-speed chain 4 is provided on the top; several foot cups 7 are fixed on the bottom of frame 1; gantry frame 2 is slidably connected on frame 1, punching assembly 3 is installed on gantry frame 2, and walking assembly It includes a rack, a gear 8 and a gantry drive motor 9, the gear 8 is connected to the inside of the gantry frame 2 in rotation, the rack is fixed on the frame 1, the gear 8 meshes with the rack, the gear 8 is connected to the gantry drive motor 9 and has a gantry drive Motor 9 drives its rotation.

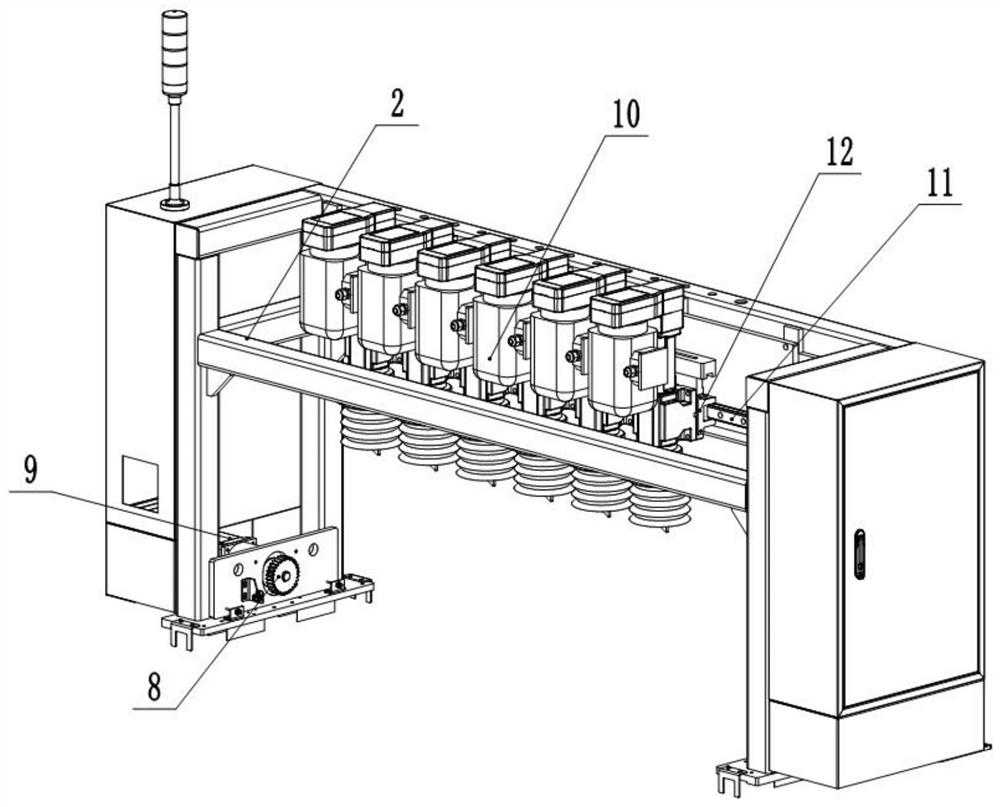

[0021] combine figure 2 As shown, the punching assembly 3 includes six groups of servo punching heads 10 and a mounting frame, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com