Collecting device for fine-grained silting sediments in modern lake

A collection device and sediment technology, which is applied in the field of sediment collection, can solve the problems of coarse-grained sediment mixing in the watershed, and achieve the effects of reducing floor space, reducing friction, and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

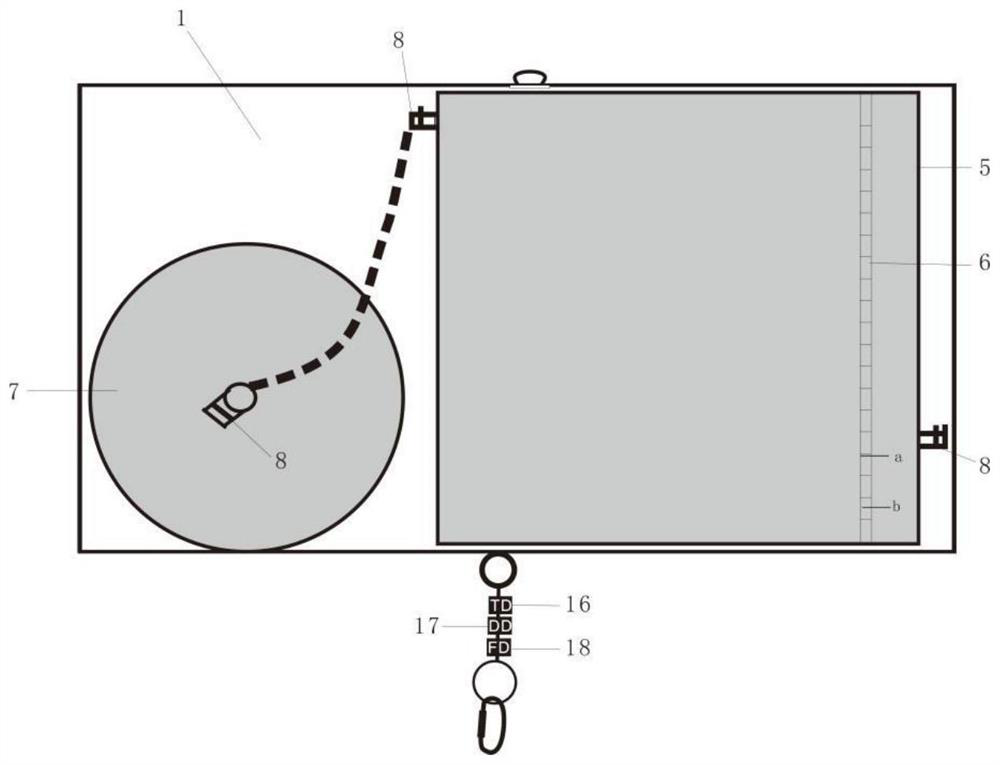

[0054] This implementation mode is regarded as a preferred embodiment of the present invention, and the specific structure is as follows Figure 1-5 As shown, it discloses the following improvements on the basis of Embodiment 1. An air chamber 5 is provided in the suspension chamber 1 , a water level limiter 6 is connected inside the air chamber 5 , and an air tank 7 is connected to one side of the air chamber 5 .

[0055] By setting the gas tank 7 and the gas cabin 5, the gas tank 7 and the gas cabin 5 are both cylindrical, and the volume ratio is between 3:5 and 4:5. The gas tank 7 is filled with N2, and the amount of N2 is smaller than that of the gas tank 7 air pressure, the water in the air chamber 5 can change the water level in the air chamber 5 through the air tank 7, thereby changing the weight of the suspension chamber 1 and the buoyancy in the water.

Embodiment 3

[0057] This implementation mode is regarded as a preferred embodiment of the present invention, and the specific structure is as follows Figure 1-5 As shown, it discloses the following improvement on the basis of Embodiment 2, the suspension cabin 1 is provided with a plurality of remote-controlled magnetic valves 8 .

[0058] By setting the remote control magnetic valve 8, it is convenient to control the lifting of the suspension cabin 1.

Embodiment 4

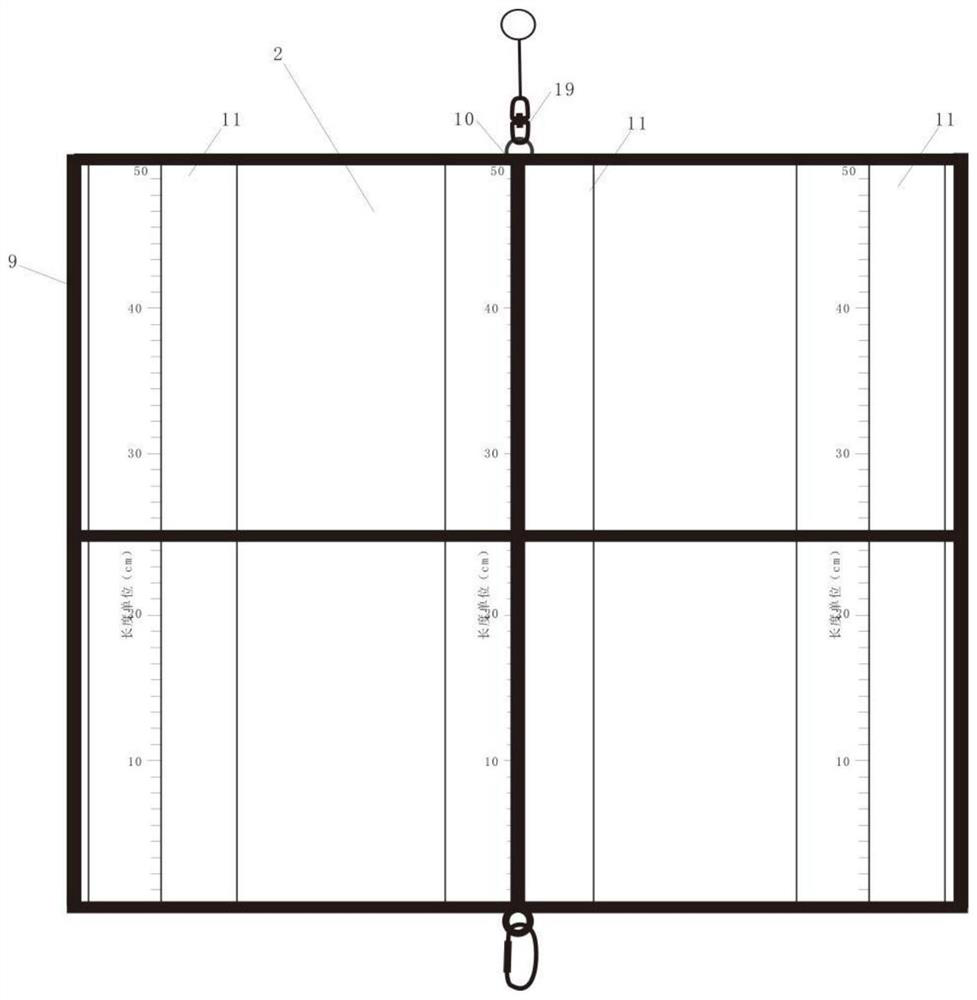

[0060] This implementation mode is regarded as a preferred embodiment of the present invention, and the specific structure is as follows Figure 1-5 As shown, it discloses the following improvements on the basis of Embodiment 3, the collector 2 includes a cylindrical collection frame 9, a cross support frame 10 is connected to the collection frame 9, and four collection cups 11 are fixedly connected to the collection frame 9 .

[0061] By setting the collection frame 9, the cross support frame 10 can support the external cylindrical frame to prevent the collection frame 9 from being deformed by the impact of external force, and the external cylindrical frame can effectively relieve the impact of the external force in the water and effectively protect the internal fixed collection cup 11 role.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com