Preparation method of hierarchical pore high-entropy alloy water electrolysis catalyst

A high-entropy alloy, multi-level pore technology, applied in the electrolysis process, electrolysis components, non-precious metal oxide coating and other directions, to achieve a wide range, simple and convenient operation, improve the oxygen production performance and cycle stability of electrolyzed water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention discloses a method for preparing a multi-level porous high-entropy alloy electrolytic water catalyst. The preparation method uses the difference in mixing enthalpy between the molten metal and the pre-alloyed components to place the smelted high-entropy transition group pre-alloy in the molten melt In the metal M, the molten molten metal M selectively reacts with its phase containing elements whose mixing enthalpy is negative to form an alloy structure with M-rich and M-poor; finally remove the more active M-rich phase in the alloy, and the remaining The components form a homogeneous three-dimensional bicontinuous, hierarchical porous high-entropy alloy water electrolysis catalyst with the characteristic of hierarchical porous structure through diffusion. Specifically include the following steps:

[0030] S1) Select transition group metals according to the design composition, and obtain transition group high-entropy pre-alloyed ingots after smelting,

[0...

Embodiment 1

[0040] (1) FeCo 1.2 Cr 0.8 Ni 1.2 MnAl 0.8 As the nominal composition of pre-alloying, the pure elements required for pre-alloying (Fe>99.999wt%, Co>99.99wt%, Cr>99.999wt%, Ni>99.9wt%, Mn>99.99wt%, Al>99.99wt% ), converted into mass (10g) according to the percentage of alloy atoms and weighed respectively, and then placed in a high-vacuum electric arc furnace to vacuum the cavity to 10 -4 Below Mpa, and filled with high-purity argon (>99.9wt%).

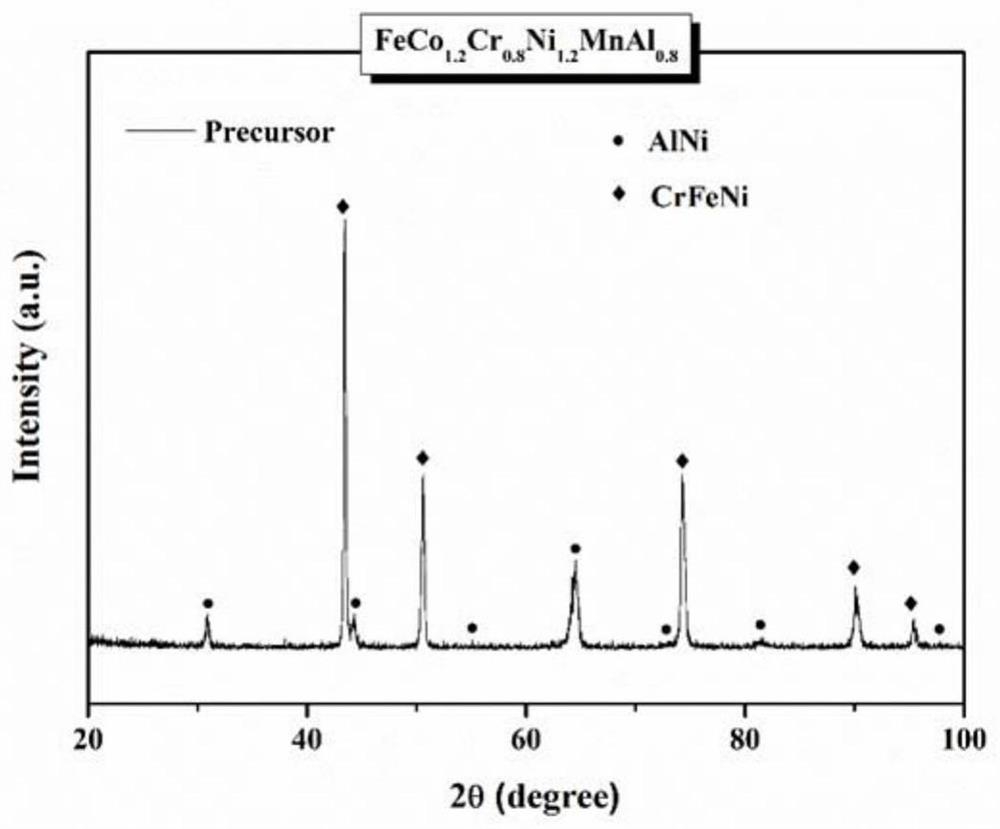

[0041] (2) Use high vacuum arc melting equipment to match the FeCo 1.2 Cr 0.8 Ni 1.2 MnAl 0.8 The initial alloy constituent materials are melted. Such as figure 1 As shown, the precursor is composed of Al-Ni-rich bcc phase and Cr-Fe-Ni-rich fcc phase.

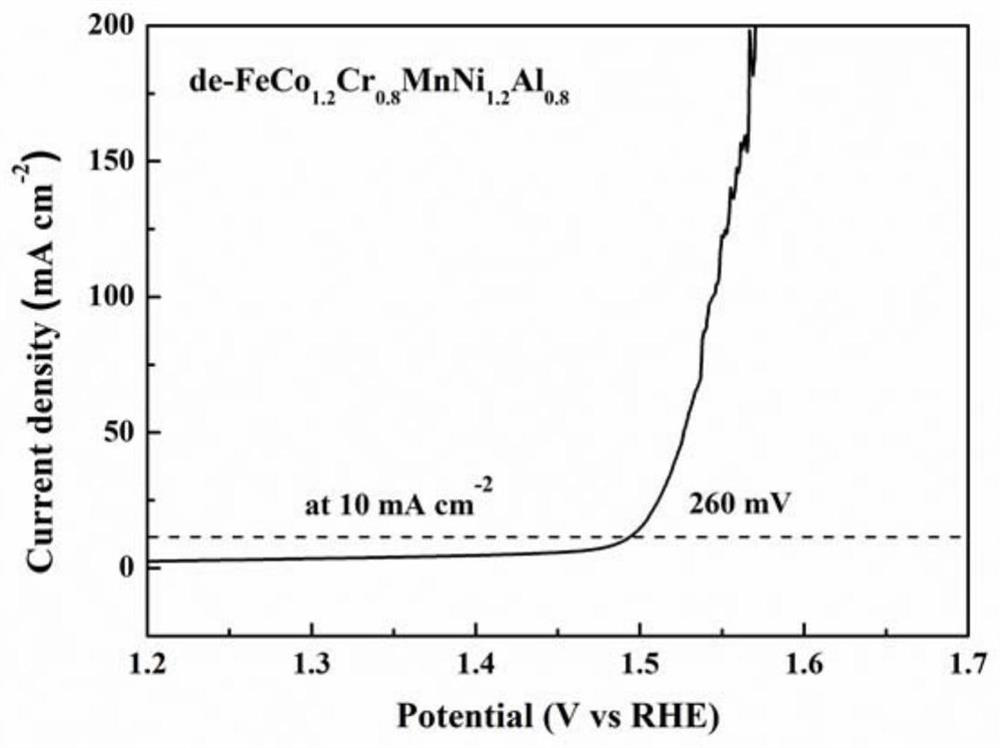

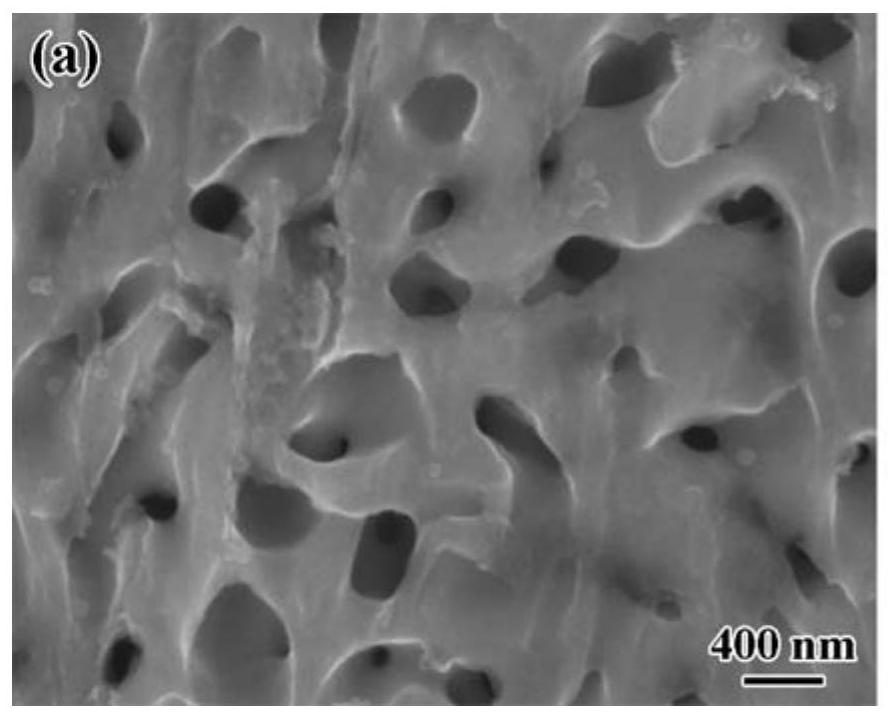

[0042] (3) Wire-cut the smelted pre-alloyed ingot to obtain thin slices of 10×10×1 mm, place the thin slices in molten magnesium, and cool to room temperature after fully reacting for 3 minutes. The Mg element combines with the rich Al-Ni phase to form the Mg-Al-Ni rich phas...

Embodiment 2

[0047] (1) with Fe 1.2 co 1.2 Cr 0.8 Ni 1.2 mn 0.8 Al 0.8 As the nominal composition of pre-alloying, the pure elements required for pre-alloying (Fe>99.999wt%, Co>99.99wt%, Cr>99.999wt%, Ni>99.9wt%, Mn>99.99wt%, Al>99.99wt% ), converted into mass (10g) according to the percentage of alloy atoms and weighed respectively, and then placed in a high-vacuum electric arc furnace to vacuum the cavity to 10 -4 Below Mpa, and filled with high-purity argon (>99.9wt%).

[0048] (2) Use high vacuum arc melting equipment to pair the prepared Fe 1.2 co 1.2 Cr 0.8 Ni 1.2 mn 0.8 Al 0.8 The initial alloy constituent materials are melted. Such as Figure 5 As shown, the precursor is composed of Al-Ni-rich bcc phase and Cr-Fe-Ni-rich fcc phase.

[0049] (3) Wire-cut the smelted pre-alloyed ingot to obtain thin slices of 10×10×1 mm, place the thin slices in molten magnesium, and cool to room temperature after fully reacting for 3 minutes. The Mg element combines with the rich Al-N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Large hole size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com