Fiber multi-dyeing device for colored spun yarn production

A multi-dyeing and color spinning technology, applied in the field of textile printing and dyeing, can solve the problems of slow processing speed, inability to batch dye, low production efficiency, etc., to reduce the thickness of the roll, overcome the uneven dyeing, and improve the dyeing speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

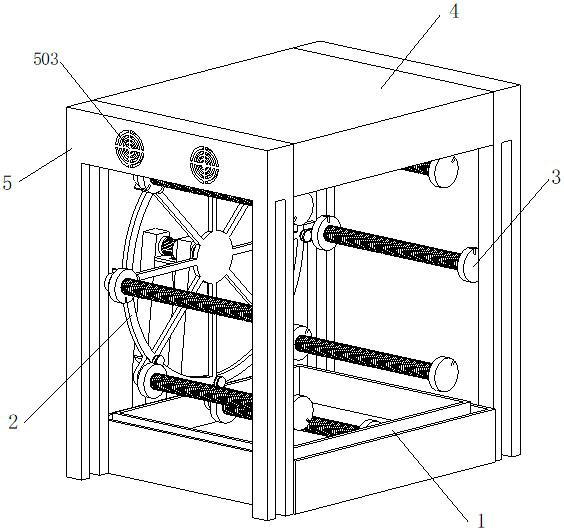

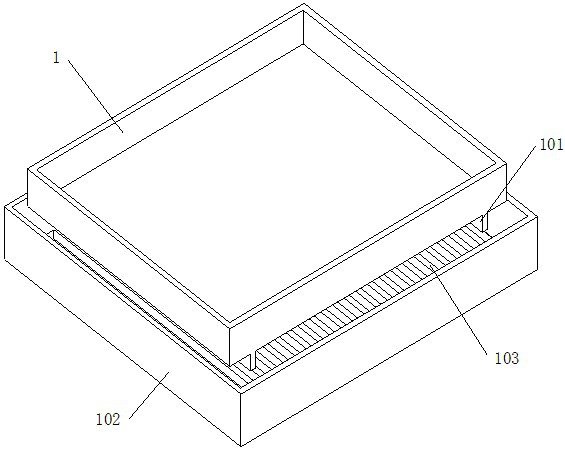

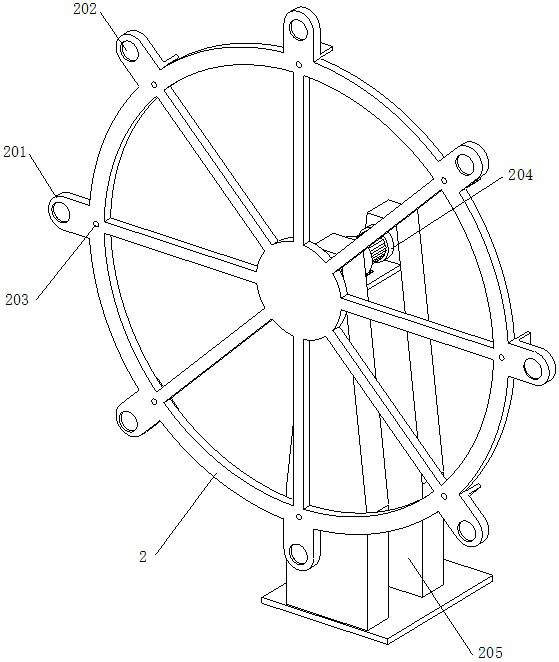

[0032] see Figure 1-6As shown, the present invention is a multi-dyeing device for fibers used in color spinning production, including a dyeing vat 1, a rotating wheel 2, a dyeing tube 3, a drying assembly 4 and an air-drying assembly 5. The rear side of the dyeing vat 1 is attached with a rotating wheel 2, The dyeing vat 1 can be used to heat the dye to ensure the activity of the dye, and the rotating wheel 2 can be used to dye large quantities of fibers and realize multiple dyeing by driving the rotation of the fibers. The front side of the rotating wheel 2 is clamped with a dyeing tube 3, The fiber can be quickly fixed through the dyeing tube 3, and the fiber can be dyed and dried evenly through the rotation of the dyeing tube 3. The two ends of the dyeing vat 1 are attache...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com