Dewatering well structure in foundation pit and construction method

A construction method and technology of dewatering wells, which are applied in infrastructure engineering, construction, etc., can solve the problems of high construction cost and construction, and achieve the effects of reducing construction workload, ensuring construction quality, and saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

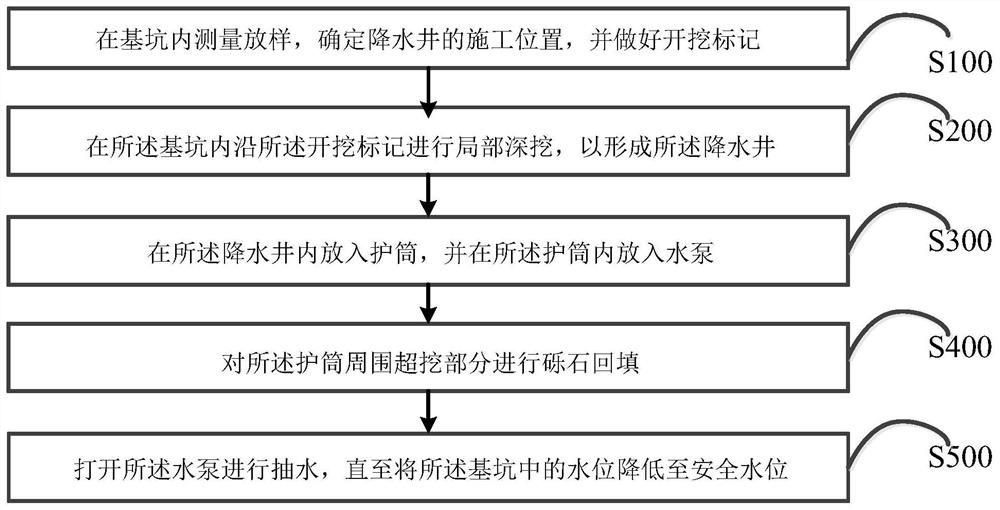

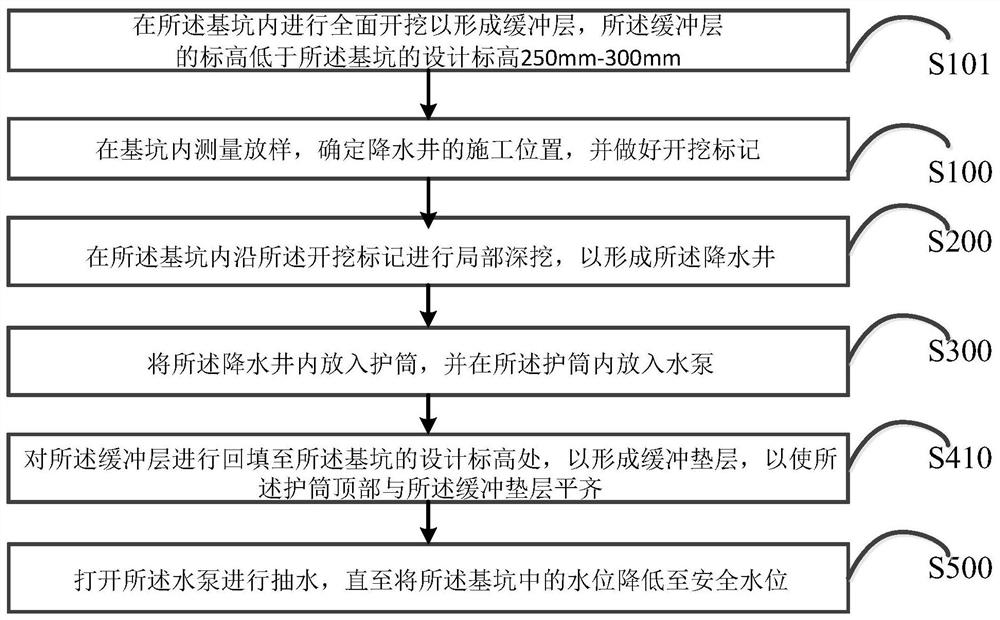

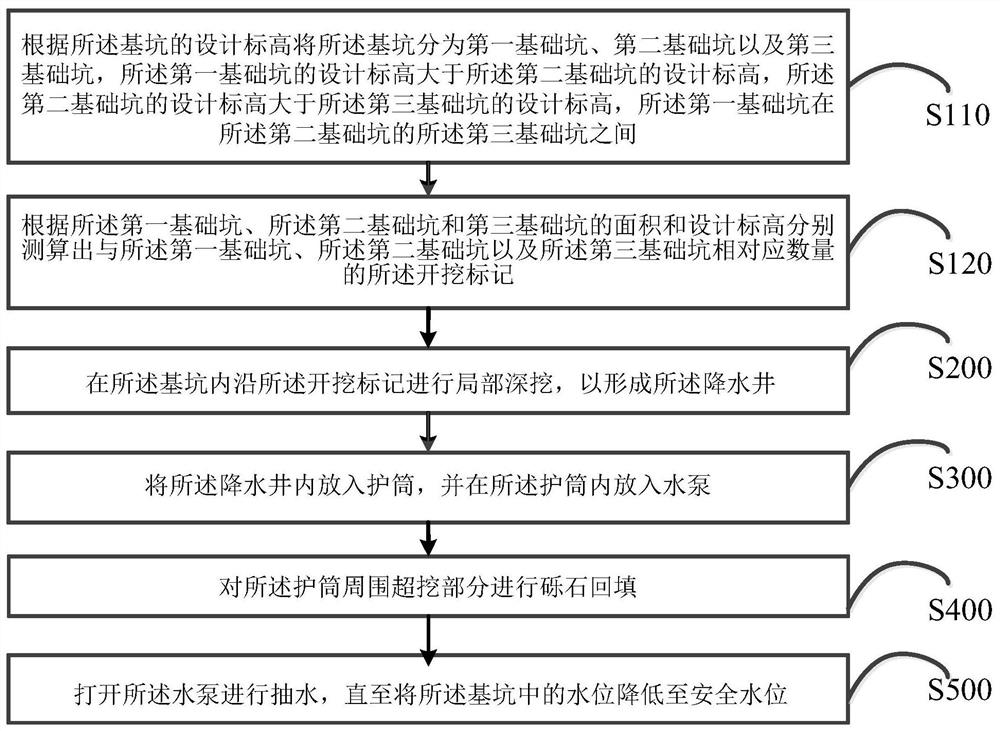

Method used

Image

Examples

no. 6 example

[0077] Based on the above embodiment, it is the sixth embodiment of the present invention, step S502 includes:

[0078] Step S5021, measuring the staked out side wall edge;

[0079] Step S5022, inserting double rows of reinforcement bars at the sideline, with an insertion depth of 0.3m-0.5m;

[0080] Step S5023, erecting the formwork of the side wall, and performing side wall pouring construction, the thickness of the side wall 2 is not less than 300mm.

[0081] Such as Figure 4 As shown, in this embodiment, the surveyor sets out the side wall 2, and inserts vertical double rows of Φ12 wall reinforcement bars 22 according to the outer edge of the side wall 2, and the wall reinforcement bars 22 have a depth of 300mm into the soil. The double row of reinforcing bars 22 further improves the strength of the side wall 2 , avoids deformation and damage of the side wall 2 caused by excessive water pressure, and further improves the construction quality of the foundation pit 100 . ...

no. 8 example

[0085] Based on the above embodiment, it is the eighth embodiment of the present invention, step S503 includes:

[0086] Step S5031, using medium sand to backfill the dewatering well to 500mm below the wellhead of the dewatering well;

[0087] Step S5032, leveling the backfill soil in the dewatering well, and pouring C35P8 micro-expansion concrete into the dewatering well to seal off the dewatering well.

[0088] In this implementation, after the concrete pouring of the side wall 2 is completed, the formwork is removed and the well is backfilled to seal the well. The backfill material of the dewatering well 1 is medium sand. The surface level is equal to the top of the cushion layer.

[0089] Based on the foregoing embodiments, step S300 includes:

[0090] Step S310, installing the water pump and its supporting circuit control facilities;

[0091] Step S320, seal the dewatering well with a cover plate, and make a protective fence around the wellhead;

[0092] Step S330, co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com