Compact anti-blocking radioactive flue gas cooling device

A flue gas cooling device and anti-clogging technology, which is applied in the direction of climate change adaptation, climate sustainability, lighting and heating equipment, etc., can solve the problem of not meeting the requirements of compact integrated design, difficult cleaning and maintenance of cooling equipment, and lack of Particle separation and other issues, to achieve efficient cooling and preliminary purification, compact structure, and minimized equipment volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

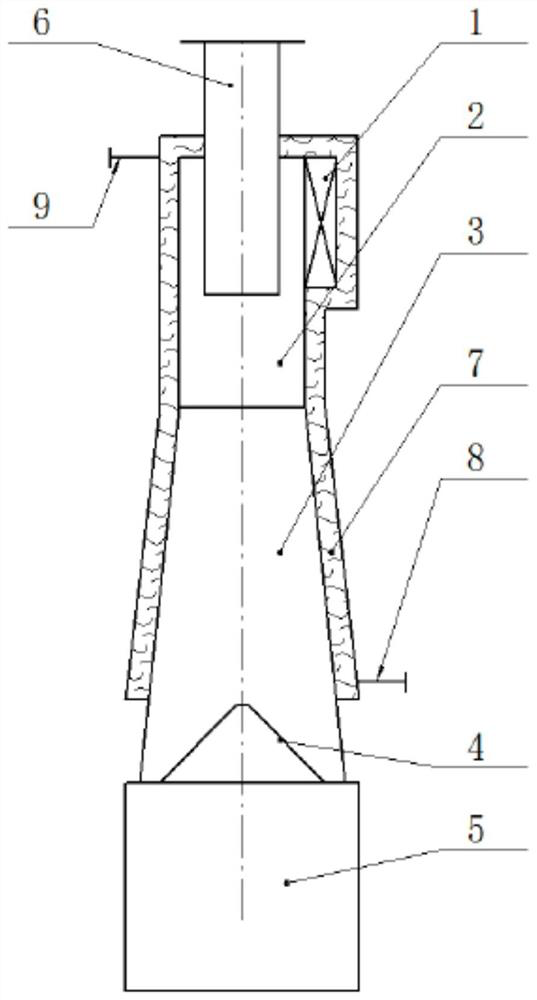

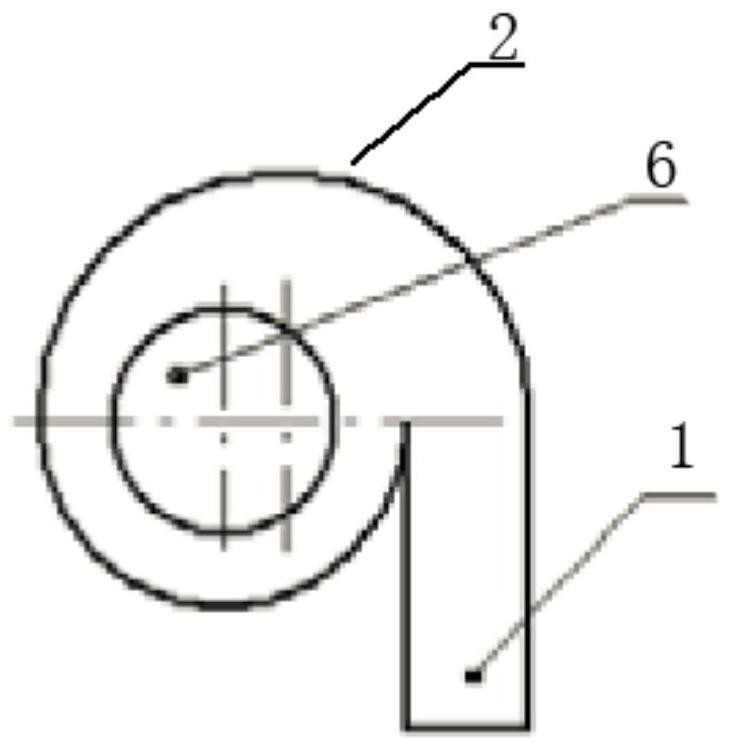

[0017] Such as figure 1 , figure 2 As shown, a compact anti-blocking radioactive fume cooling device includes an inner shell, an ash hopper 5 installed at the bottom of the inner shell, an air intake pipe 1 arranged on the top of the inner shell and communicated with the inner shell, and an air intake pipe 1 is connected tangentially to the cylinder 2, and the flue gas enters the cylinder 2 tangentially through the intake pipe 1. The inner shell includes the cylinder 2 and the cone 3 connected to the cylinder 2. The cylinder 2 and the cone 3 are integrated. Forming, the cone 3 is in the shape of an inverted cone, the bottom of the cone 3 is provided with a reflective screen 4, the top of the reflective screen 4 is provided with air holes, and there is an annular gap between the reflective screen 4 and the inner wall of the cone 3, the cone 3 The inner cavity of the ash hopper communicates with the inner cavity of the ash hopper 5 through the vent holes on the reflective scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com