Eddy current self-heating nitrogen replacement and detoxification device for dioxin-containing fly ash

A nitrogen replacement and self-heating technology, which is applied in waste heat treatment, heating room maintenance, lighting and heating equipment, etc., can solve the problems of high pollution products, instability, etc., and achieve the effect of improving completeness and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

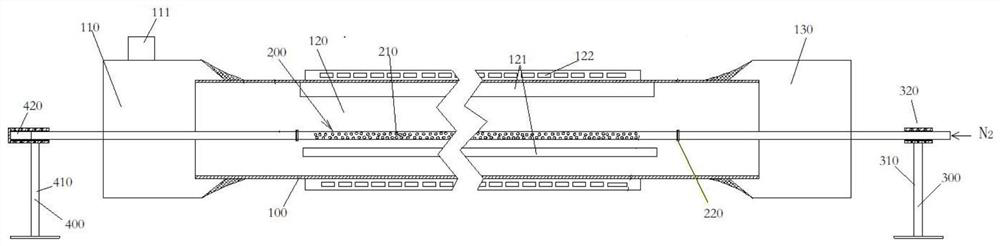

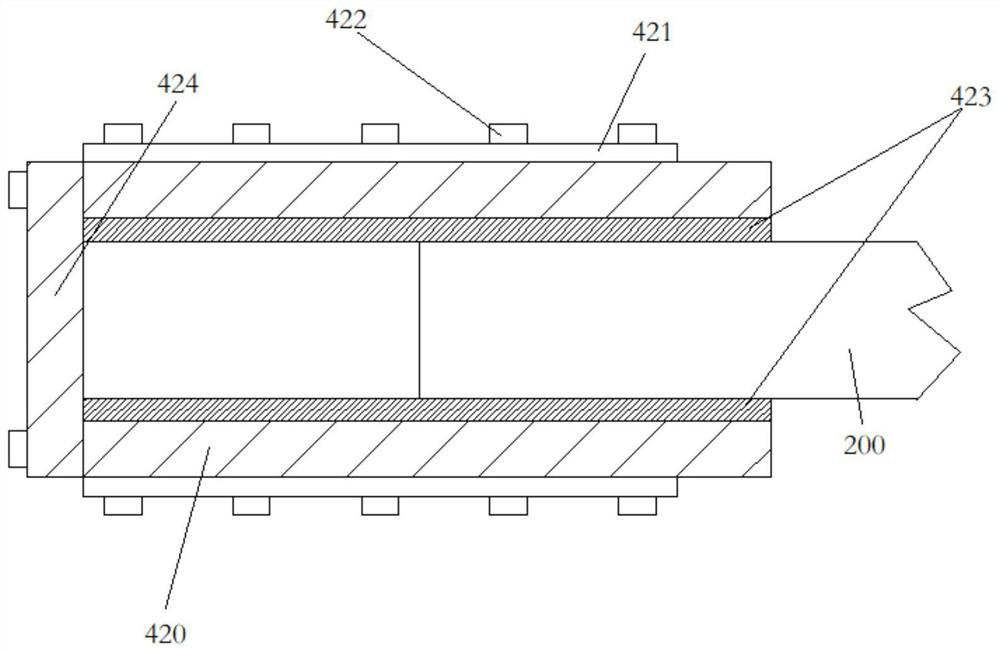

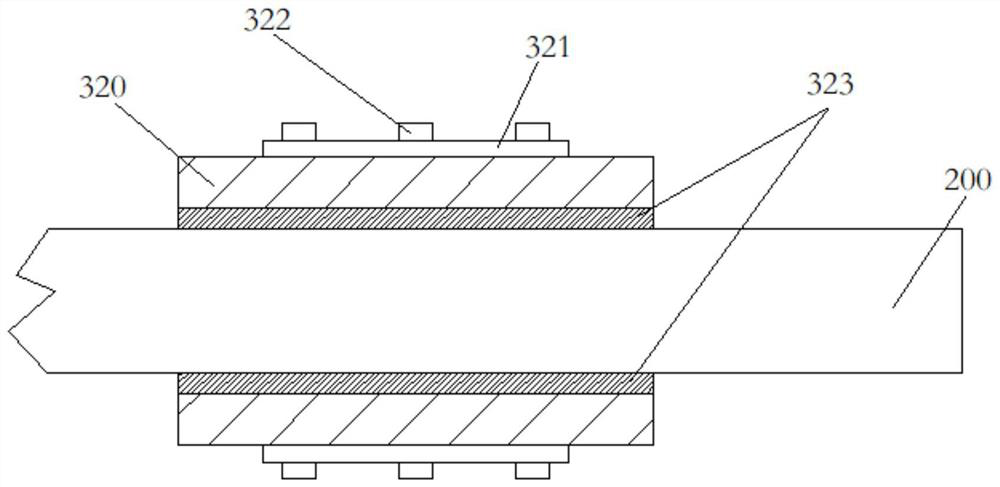

[0028] like Figure 1-4 The shown vortex self-heating nitrogen replacement and detoxification device containing dioxin-containing dust removal ash includes a rotatable kiln body 100. The vortex self-heating rotary kiln is selected, and the temperature rises rapidly, avoiding the start-up and shutdown time of traditional fuel kilns. Long, the disadvantages of high energy consumption.

[0029] The kiln body 100 is a hollow structure, with a preheating section 110 , a heating section 120 and a cooling section 130 arranged in a three-stage structure inside; the heating section 120 is wrapped with an induction heating device 122 .

[0030] The inductive heating device 122 has flexible and precise temperature control, good displacement reaction effect, high dioxin removal efficiency, and safer products.

[0031] Using electricity as the heat source, there is no need to supplement oxygen in the kiln to support fuel combustion, and the kiln is a reducing atmosphere, which is conduciv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com