Crystallizer casting powder applied to high-speed continuous casting

A mold powder and mold powder technology, applied in the field of metallurgy, can solve the problems of surface defect cohesion, breakout, and continuous casting mold powder consumption reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The exothermic agent used in Example 1 is composed of calcium carbide and silicon-calcium alloy (Ca: 40wt%, Si: 60wt%) in a mass ratio of 1:1.

Embodiment 2

[0063] The exothermic agent used in Example 2 was composed of silicon-calcium alloy (Ca: 40 wt%, Si: 60 wt%).

Embodiment 3

[0064] The exothermic agent used in Example 3 was composed of silicon-calcium alloy (Ca: 45 wt%, Si: 55 wt%).

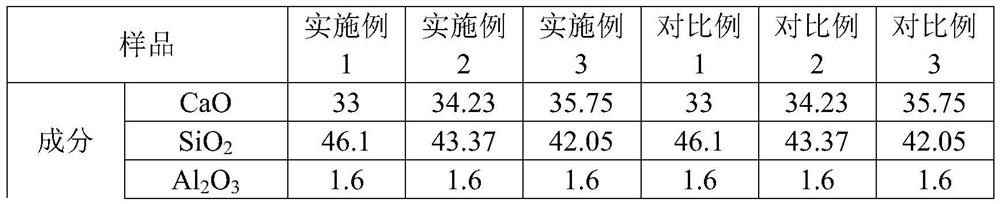

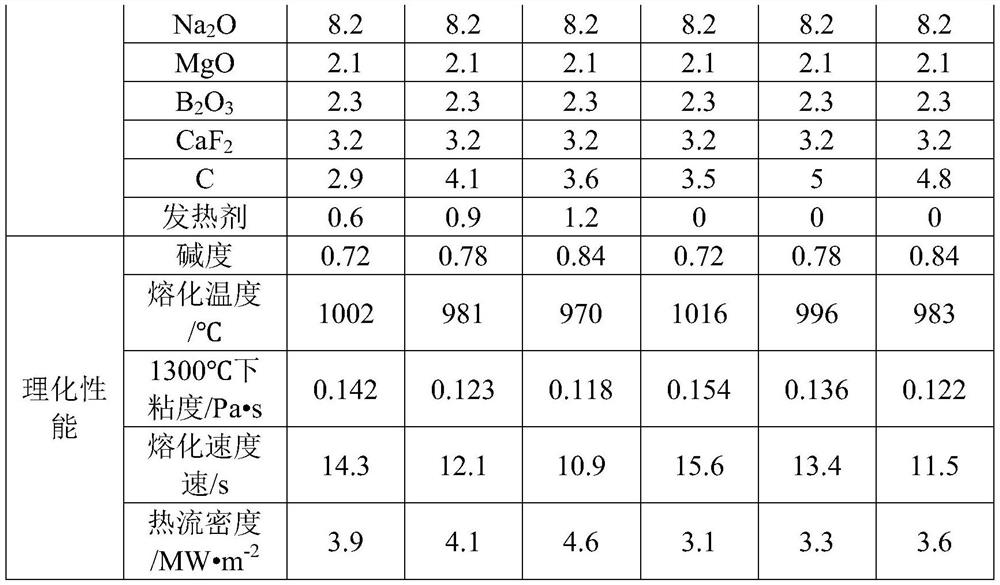

[0065] It can be seen from Table 1 that the melting temperatures of Examples 1 to 3 are 1002°C, 981°C, and 970°C respectively; the viscosities at 1300°C are 0.142Pa·s, 0.123Pa·s, and 0.118Pa·s; the heat fluxes are 3.9MW respectively m -2 , 4.1MW·m -2 , 4.6MW·m -2 .

[0066] It can be seen from Table 1 that the melting temperatures of Comparative Examples 1 to 3 are 1016°C, 996°C, and 983°C respectively; the viscosities at 1300°C are 0.154Pa·s, 0.136Pa·s, and 0.122Pa·s; the heat fluxes are 3.1MW respectively m -2 、3.3MW·m -2 , 3.6MW·m -2 .

[0067] Comparing Examples 1 to 3 and Comparative Examples 1 to 3, it can be found that: the high casting speed mold flux added with exothermic agent has lower viscosity and melting temperature than the high casting flux without exothermic agent, and faster Melting speed, at the same time has a good lubricating ability, for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com