Sound-absorbing felt processing equipment and processing technology

A processing equipment and felt technology, applied in the field of sound-absorbing felt processing equipment and processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The embodiment of the present application discloses a sound-absorbing felt processing equipment.

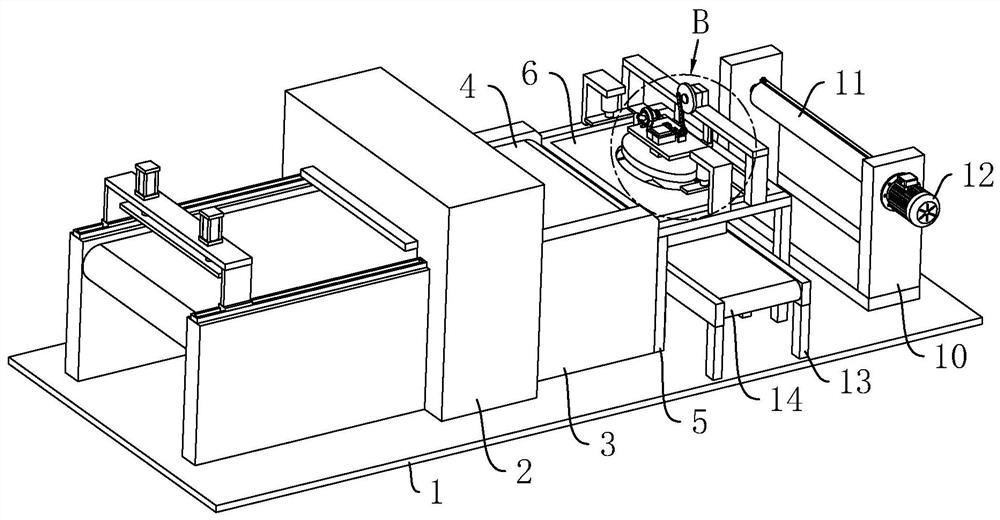

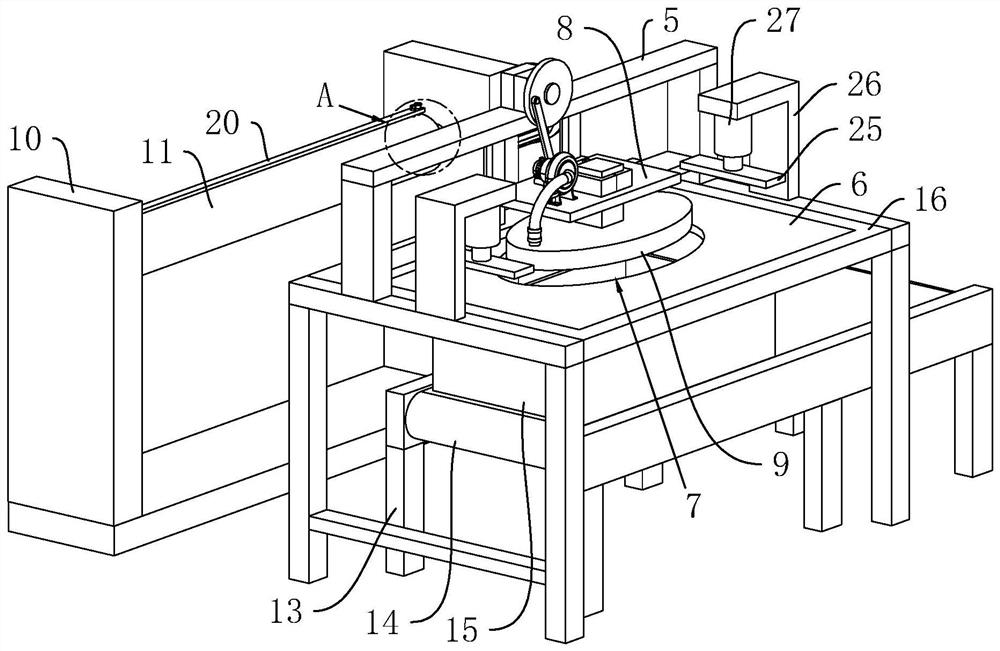

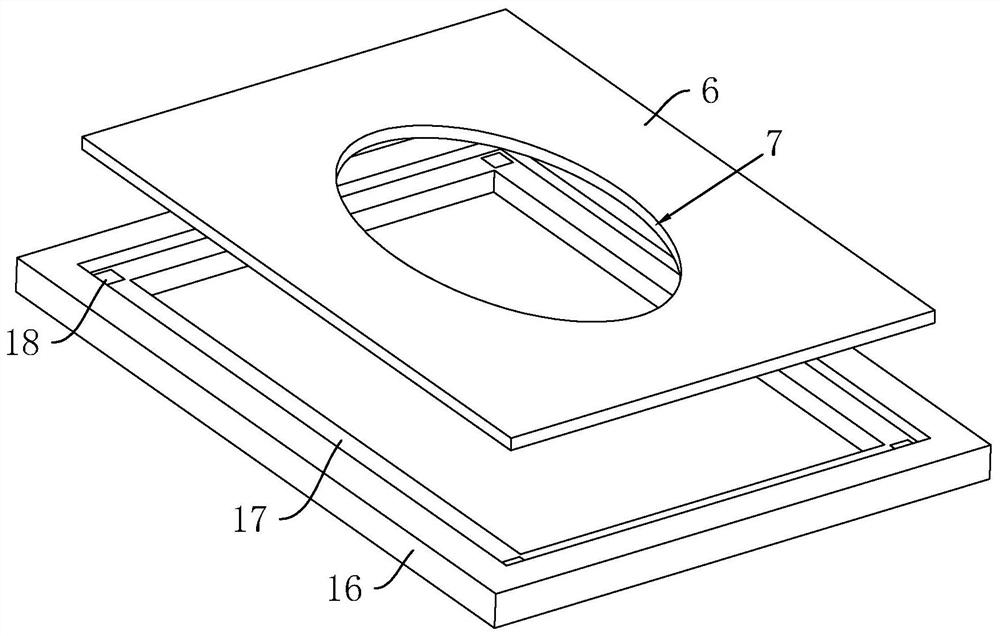

[0047] refer to figure 1 and figure 2 , a sound-absorbing felt processing equipment, including a bottom plate 1 and a body 2, the body 2 is fixedly connected to the bottom plate 1, the body 2 is fixedly connected to a first bracket 3, and the first bracket 3 is rotatably connected to a first timing belt 4. The first bracket 3 is fixedly connected to the discharge end of the first synchronous belt 4 with a mounting frame 5, the mounting frame 5 is detachably provided with a lower template 6, and the lower template 6 is provided with a discharge port 7 along the vertical direction.

[0048] refer to figure 2 , the mounting frame 5 is provided with a positioning assembly for fixing the sound-absorbing felt, the mounting frame 5 is slidably connected with a lifting plate 8 along the vertical direction, and the side of the lifting plate 8 facing the discharge port 7 is deta...

Embodiment 2

[0078] refer to Figure 1-6 , the application discloses a sound-absorbing felt processing technology, comprising the following steps,

[0079] S1: Determine the moving path, pass one end of the sound-absorbing felt under the knife mold of the body 2, and then make the sound-absorbing felt pass between the upper die head 9 and the lower template 6, and move the end of the sound-absorbing felt away from the lower template 6 to the receiving end. Between the waste roller 11 and the layer 20, two bolts 21 are tightened through the first handle 24, so that the sound-absorbing felt is clamped between the waste roller 11 and the layer 20, and one end of the sound-absorbing felt is fixed to the waste roller 11;

[0080] S2: Die-cutting, the first synchronous belt 4 is running, the sound-absorbing felt follows the first synchronous belt 4 and enters the body 2 for die-cutting, and then the finished sound-absorbing felt and leftovers continue to follow the first synchronous belt 4 and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com