Down jacket fabric capable of inhibiting bacterium breeding and preparation method of down jacket fabric

A down jacket fabric, a technology for inhibiting bacteria, applied in the field of down jacket fabrics, can solve the problems of down jacket bacteriostasis, weakened antibacterial power, and reduced use value of down jackets, etc., and achieves good bacteriostatic effect, reduced washing friction area, and long action time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

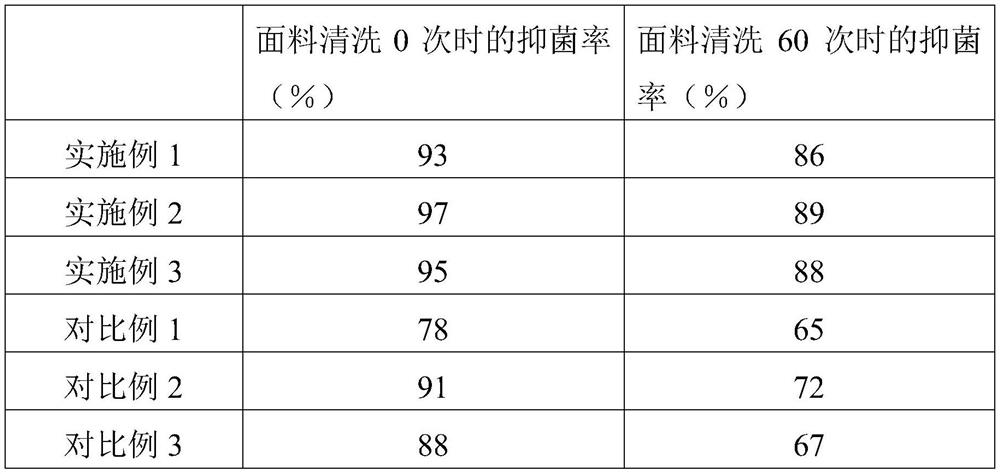

Examples

Embodiment 1

[0032] A down jacket fabric that inhibits the growth of bacteria, comprising:

[0033] Outer layer; the outer layer is made of outer layer fibers and antibacterial fibers with a mass ratio of 7:3; wherein, the outer layer fibers (by weight) include 65 parts of polyester cationic fibers and seaweed biobased Fiber 35 parts;

[0034] Inner layer; the inner layer is made of inner layer fiber and antibacterial fiber with a mass ratio of 3:2; wherein, the inner layer fiber (by weight) includes 60 parts of polyester cationic fiber and corn bio-based 40 parts of fiber;

[0035] Adhesive layer; the adhesive layer is made of a mixture of antibacterial fiber and glue with a mass ratio of 2:3, and the glue is hot-melt adhesive. The adhesive layer bonds the outer layer and the inner layer and forms a down-filled partition ;

[0036] Wherein, the antibacterial fiber (by weight) includes 40 parts of coconut carbon fiber, 25 parts of chitin, 15 parts of antibacterial powder, 24 parts of so...

Embodiment 2

[0045] A down jacket fabric that inhibits the growth of bacteria, comprising:

[0046] Outer layer; the outer layer is made of outer layer fibers and antibacterial fibers with a mass ratio of 8:2; wherein, the outer layer fibers (by weight) include 70 parts of polyester cationic fibers and seaweed biobased 30 parts of fiber;

[0047] Inner layer; the inner layer is made of inner layer fiber and antibacterial fiber weaving with a mass ratio of 3.5:1.5; wherein, the inner layer fiber (by weight) includes 70 parts of polyester cationic fiber and corn bio-based 30 parts of fiber;

[0048] Adhesive layer; the adhesive layer is made by mixing antibacterial fiber and glue with a mass ratio of 1.5:3.5, and the glue is hot-melt adhesive. The adhesive layer bonds the outer layer and the inner layer and forms a down-filled partition ;

[0049] Wherein, the antibacterial fiber (by weight) includes 45 parts of coconut carbon fiber, 22 parts of chitin, 18 parts of antibacterial powder, 1...

Embodiment 3

[0058] A down jacket fabric that inhibits the growth of bacteria, comprising:

[0059] Outer layer; the outer layer is made of outer layer fibers and antibacterial fibers with a mass ratio of 9:1; wherein, the outer layer fibers (by weight) include 75 parts of polyester cationic fibers and seaweed biobased Fiber 25 parts;

[0060] Inner layer; the inner layer is made of inner layer fiber and antibacterial fiber with a mass ratio of 4:1; wherein, the inner layer fiber (by weight) includes 80 parts of polyester cationic fiber and corn biobased Fiber 20 parts;

[0061] Adhesive layer; the adhesive layer is made by mixing antibacterial fiber and glue with a mass ratio of 1:3, and the glue is hot-melt adhesive. The adhesive layer bonds the outer layer and the inner layer and forms a down-filled partition ;

[0062] Wherein, the antibacterial fiber (by weight parts) includes 50 parts of coconut carbon fiber, 19 parts of chitin, 23 parts of antibacterial powder, 12 parts of sodium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com