Universal wheel bearing type vehicle carrying plate embracing exchange type AGV

A technology of vehicle-carrying boards and moving vehicles, which is applied in the direction of motor vehicles, building types, transportation and packaging, etc., and can solve the problems of long construction period, low site utilization rate, and poor site applicability of full-load submerged and top-height AGV transport vehicles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The invention is further illustrated below with reference to the accompanying drawings and examples.

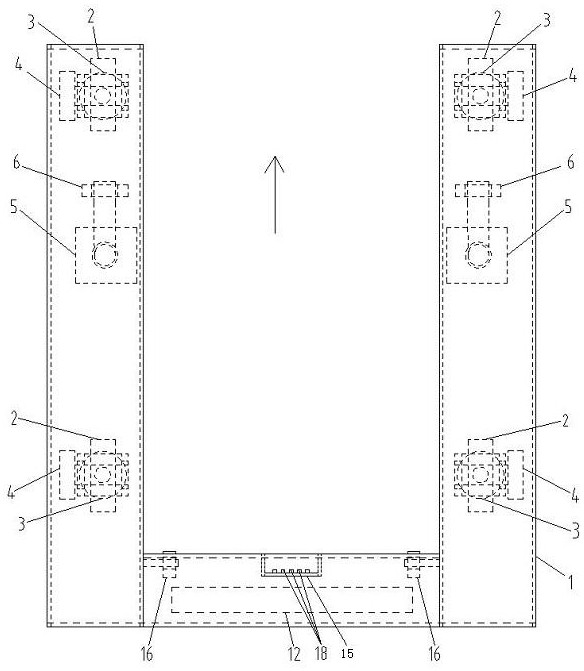

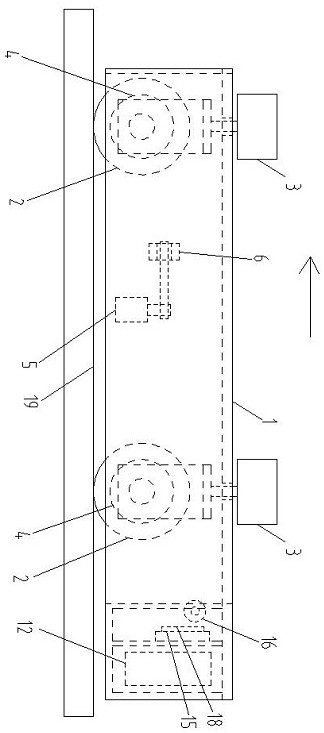

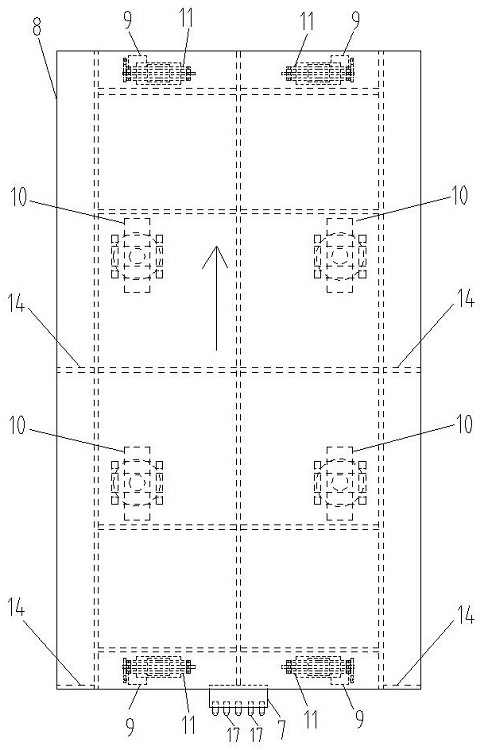

[0015] See figure 1 Attachment figure 2 Attachment image 3 Attach Figure 4The direction of the arrow is forwarded, top view, the main structure of the circumferential exchanged vehicle chassis 1 is U-shaped; view and left view, the corresponding position of the circumferential switching vehicle chassis 1 is fixed, respectively, two axial rudder wheel assembly 2, rotary positioning motor 5, control host 12, conductive socket 15, roller II16; fixed to the front end position of the output arm of the rotation positioning motor 5, respectively, the roller I6 is fixed, respectively; the corresponding position at the lower portion of the carrier board 8 is fixed to the set universal wheel, respectively, respectively 10, the motor screw drive type cutting device 11; corresponding to the roller I6 and the roller II16, the positioning block 14 is fixed in the corresponding position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com