Method for improving wave resistance of amphibious aircraft based on active flow control technology

A technology of active flow control and amphibious aircraft, which is applied to seaplanes, aircraft, motor vehicles, etc., and can solve problems such as impact load on the body and large impact of water take-off and landing, poor adaptability of amphibious aircraft, hull roll, pitch, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

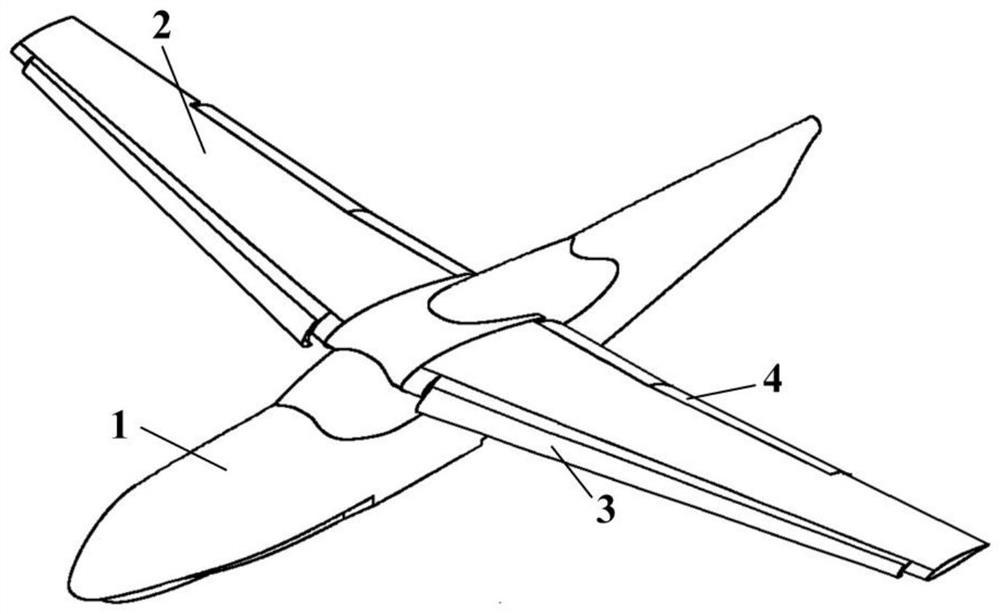

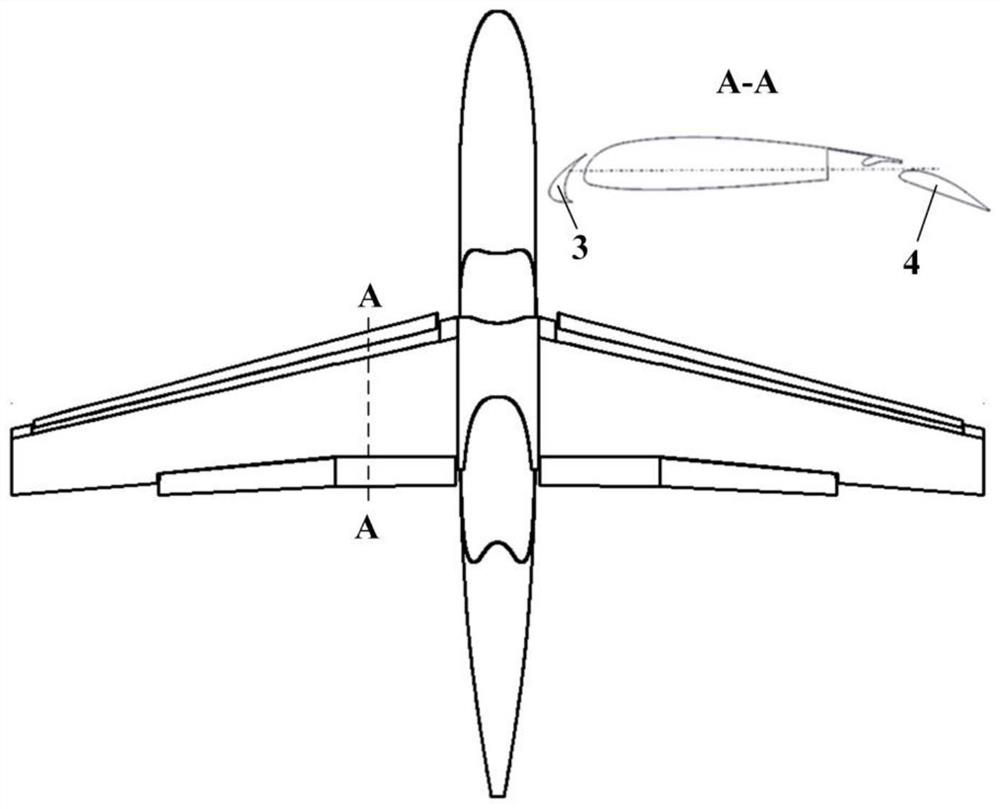

[0034] like Figure 1 to Figure 6 As shown, the embodiment of the present invention discloses a method for improving the anti-wave performance of an amphibious aircraft based on active flow control technology. "V-shaped" hull fuselage 1, upper single-swept wing 2, leading edge slat 3, trailing edge flap 4; the total length of the wing body assembly is 33.948m, and the wingspan is 42.03m; the verification The calculation conditions are the take-off state, the Mach number of the incoming flow is 0.2, and the altitude is 0km.

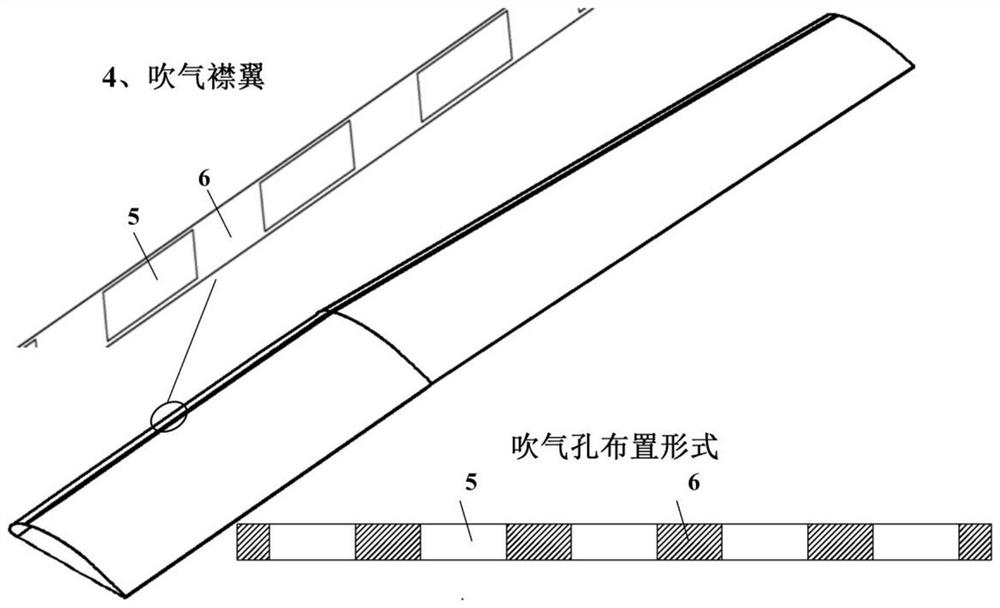

[0035] further, such as figure 2 As shown in the wing section, the basic lift device is composed of leading edge slats 3 and trailing edge flaps 4 . The relative chord length of the leading edge slat is 0.15, the slot width is 2%C, the overlap is 0.5%C, and the take-off state is deflected by 20°; The track width is 2%C, the overlap is 0.5%C, in the take-off state, the deflector does not protrude in the flap compartment, and the main flap is deflected b...

Embodiment 2

[0042] like Figure 7 ~ Figure 10 As shown, the present invention discloses another embodiment of a method for improving the anti-wave performance of an amphibious aircraft based on the active flow control technology. This embodiment mainly applies the active flow control technology to the vertical tail rudder surface, and its main structure includes : vertical tail stabilizer 6, rudder surface 7, air blow hole 5 and spacer 6.

[0043] further, such as Figure 7 As shown, the vertical tail 6 is a trapezoidal wing with a sweep angle of 32°, an aspect ratio of 1.35, and a trapezoidal ratio of 0.8; the vertical tail adopts a NACA symmetrical airfoil with a maximum thickness of 10%; the rudder 7 The relative area is 0.3, the maximum deflection angle is 20°; the calculation conditions are the take-off state, the rudder deflects 20°, the incoming flow velocity is the take-off speed 40m / s, the angle of attack is 0, and the altitude is 0km.

[0044] further, such as Figure 7 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com