Manufacturing method of four-point contact flexible bearing harmonic reducer

A technology of harmonic reducer and flexible bearing, used in manufacturing tools, assembly machines, belts/chains/gears, etc., can solve the problem of poor connection effect between rigid wheel and cross bearing, affecting the use effect of harmonic reducer, looseness, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

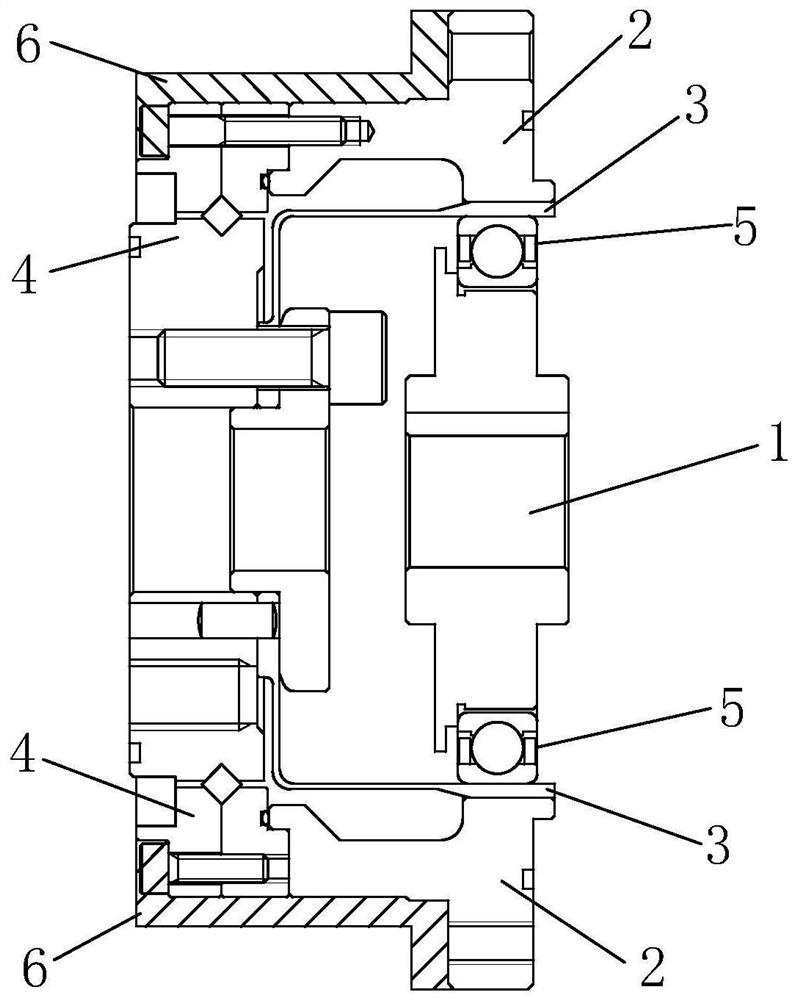

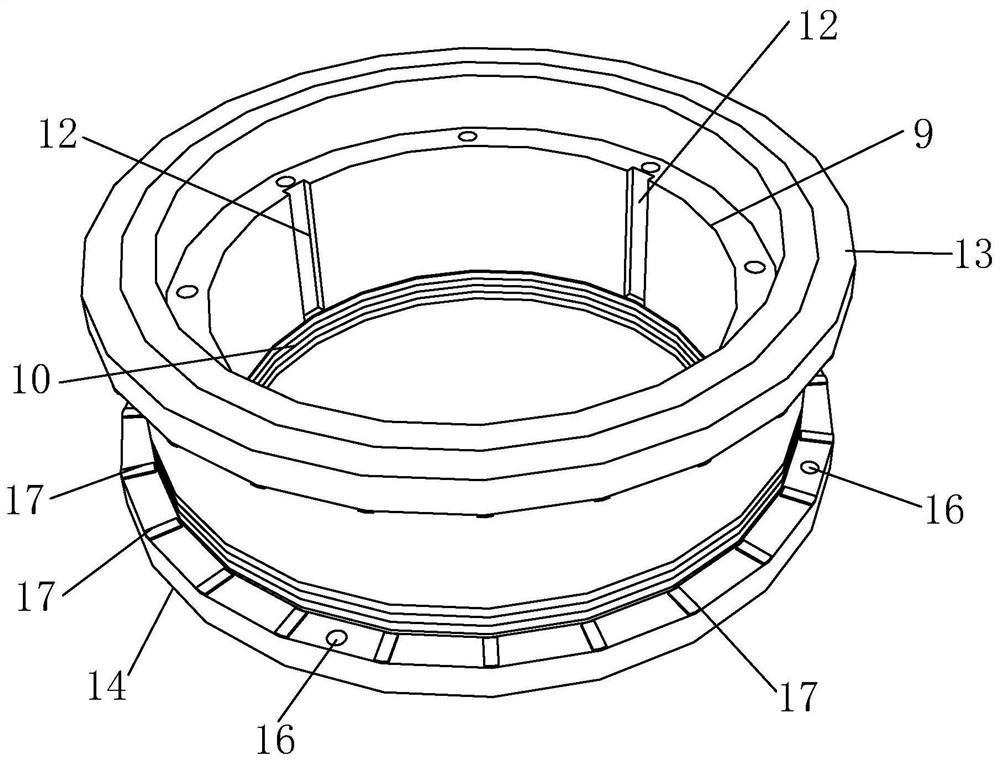

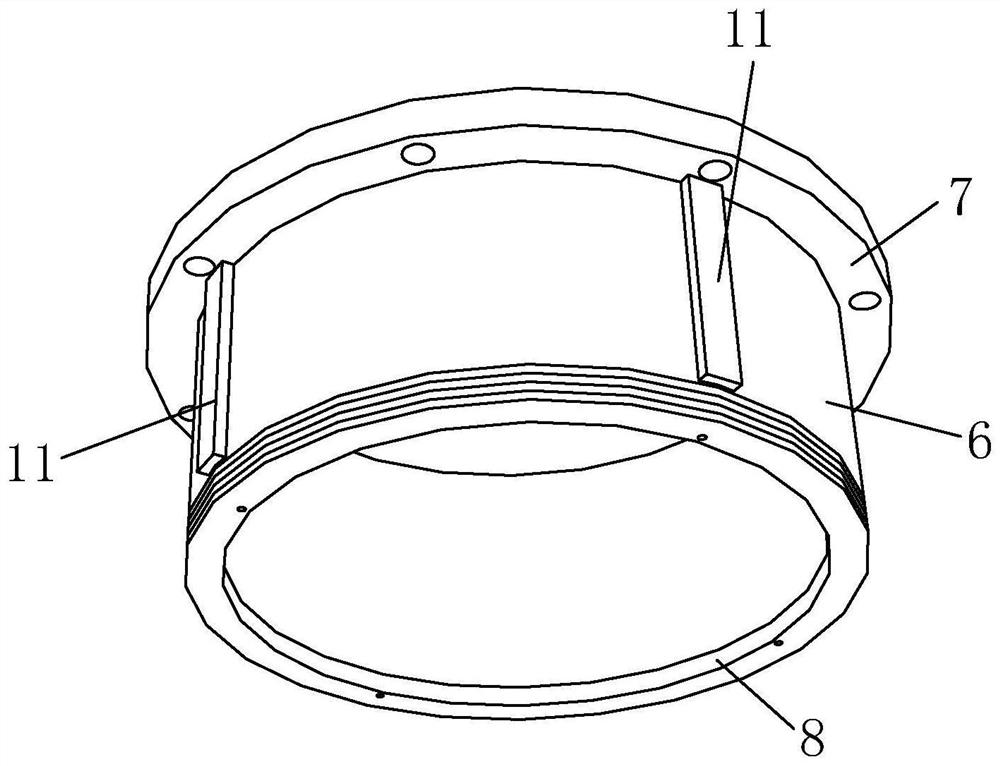

[0051] Such as Figure 1 to 4 As shown, for the present invention, a four-point contact flexible bearing harmonic reducer comprises wave generator 1, the rigid wheel 2, the flexo wheel 3 and the cross bearing 4, and the wave generator is provided with four points of contact flexible bearing 5, four points. The contact flexible bearing 5 is provided in the flexion wheel 3, and the flexo wheel 3 is provided in the rigid wheel 2 and engages with the rigid wheel 2, and the inner ring of the cross bearing 4 is fixedly connected, and the outer ring of the intersecting bearing 4 is with the rigid wheel. 2 Secure connection, the rigid wheel 2 is provided with a support ring 6, and the support ring 6 is provided with a first support ring 7 and a second support ring 8. The first support ring 7 is connected to the rigid wheel 2 bolt, the second support ring 8 and the intersection bearing. 4 bolt connection. Four-point contact flexible bearing 5 specifically includes an inner ring, outer ring,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com