High polymer gravel protection device for eliminating near-field underwater blasting shock waves

A protective device and polymer technology, which is applied in the field of polymer gravel protective devices, can solve the problems of unsatisfactory attenuation effect and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

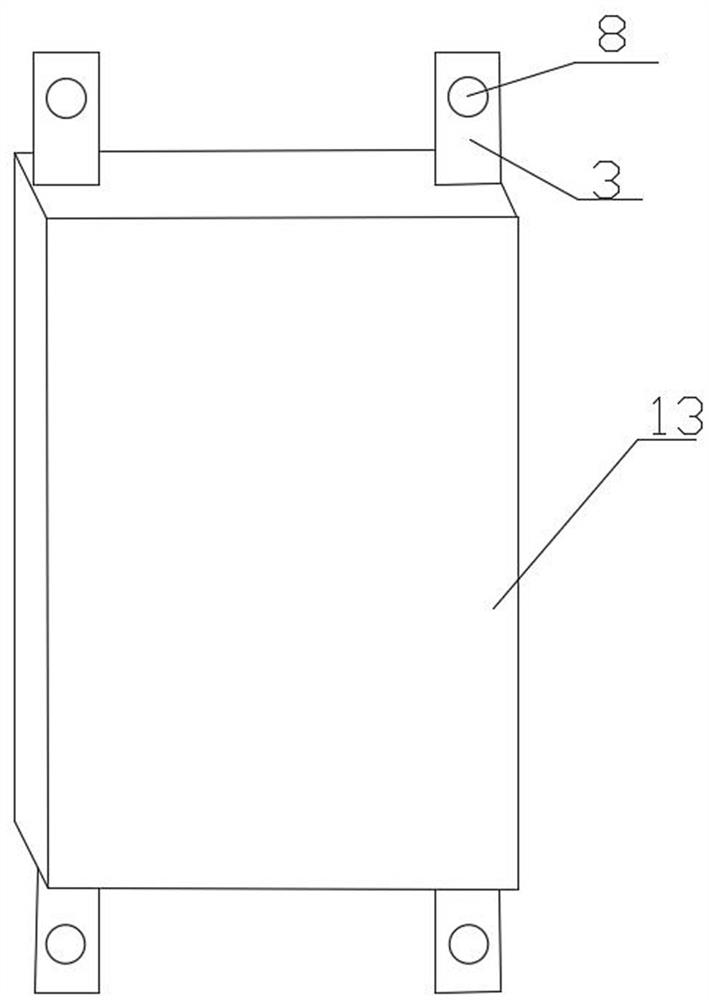

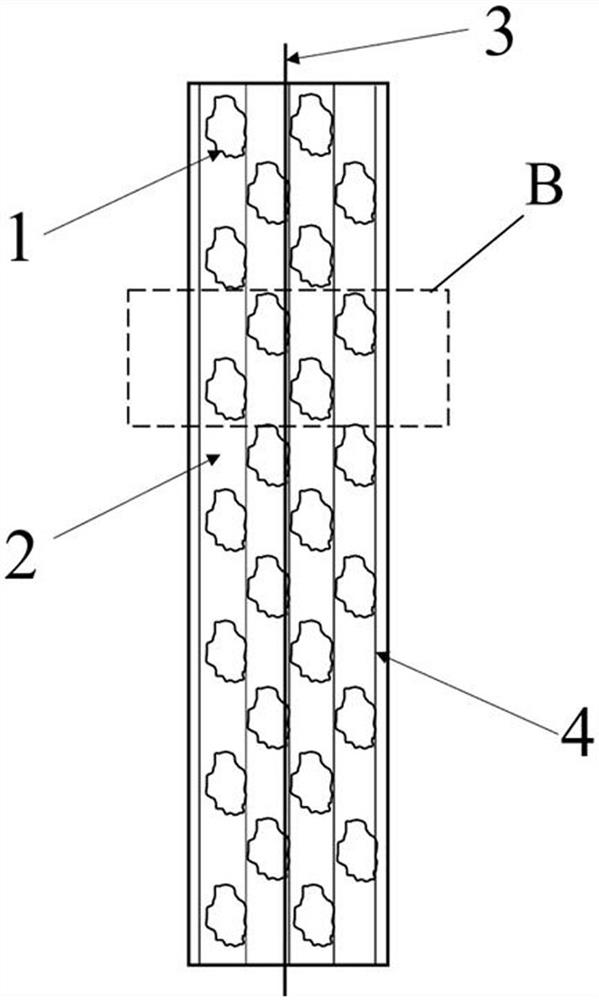

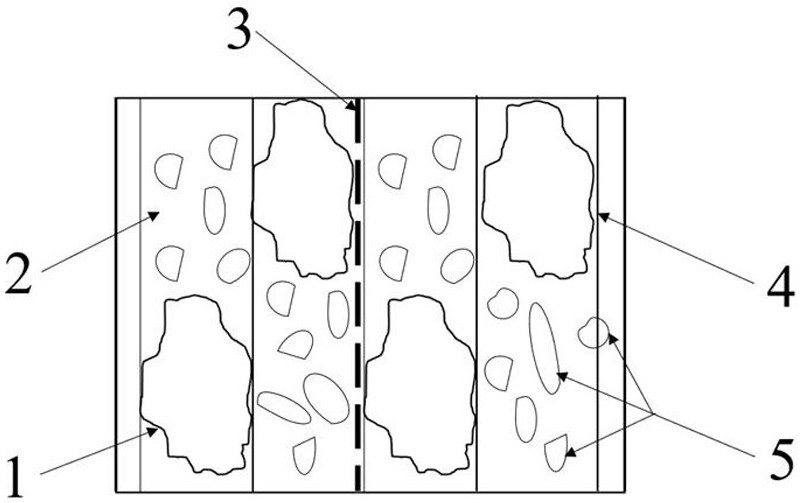

[0023] like Figure 1-Figure 3 As shown, a polymer gravel protection device for eliminating the shock wave of underwater near-field blasting, including polymer 2, barbed wire 4 arranged in parallel, gravel 1 and steel plate 3, and the space between the barbed wire 4 is filled with gravel 1 to form a protective body, and then pour high polymer to form a protective mechanism 7, both sides of the protective mechanism 7 are pre-embedded with steel plates 3, such as Figure 8 As shown, the steel plate 3 adopts a thin steel plate with a thickness of 5-10 mm and a width of 5-10 cm. The two ends of the steel plate 3 protruding from the protective mechanism form lifting lugs, and a lifting hole 8 is opened on the lifting lugs. Before pouring, the steel plate Buried in the protection mechanism, bolts or ropes are used to assemble the invention with the help of hoisting holes, which is convenient for assembly and suspension arrangement. The steel plate is evenly distributed with circular...

Embodiment 2

[0034] like Figure 4 , Figure 5 As shown, the gravel of this embodiment is smooth in surface, approximately oval or round, with a particle size of about 3 cm and a density of about 2.5 g / cm 3 Pebble 6, the particle size of the crushed stone is basically the same, the crushed stone has a certain hardness, the surface is clean, and there is no debris attached.

[0035]The specific implementation process of this embodiment repeats the above-mentioned embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com