A space product fire extinguisher structure and its manufacturing method and space product

A product and space technology, applied in the fire extinguisher structure of space products and the field of space products, can solve the problems of electromagnetic wave leakage, short circuit or aging of internal devices, and failure to meet the functional requirements of microgravity operation, so as to achieve good shielding effect and avoid aging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

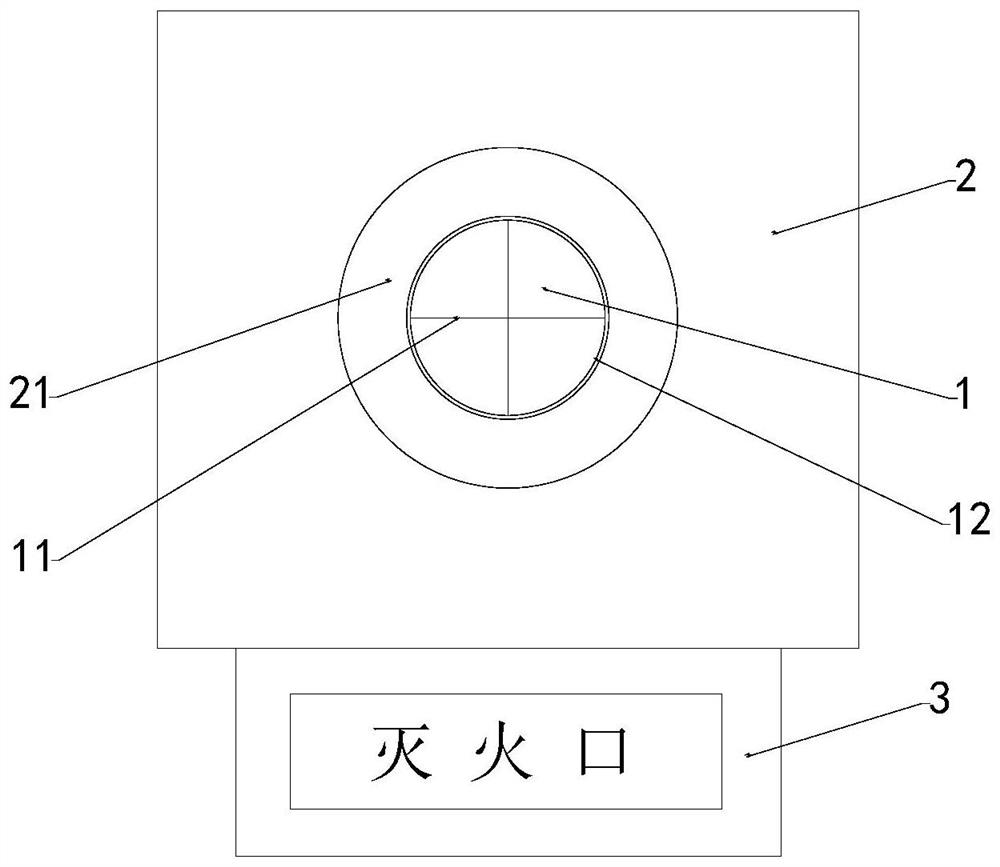

[0035] Such as figure 1 As shown, the structure of a fire extinguisher for a space product in this embodiment includes pasting an electromagnetic shielding cloth 1 at the through hole of the fire extinguisher, and the electromagnetic shielding cloth 1 is provided with a hole for piercing the electromagnetic shielding cloth 1 to enter the through hole of the fire extinguisher. grooved. When the through hole of the fire extinguisher is not suitable, the electromagnetic shielding cloth is pasted to meet the EMC requirements. After a fire occurs in orbit, the astronauts can use the fire extinguisher to quickly open the electromagnetic shielding cloth to extinguish the fire.

[0036] Wherein, the through hole of the fire extinguisher in this embodiment can be square, circular or any other shape, preferably circular, with a diameter of 12-16mm, preferably 13mm, 14mm, 15mm, through which the fire extinguishing operation can be carried out.

[0037] Such as figure 1 As shown, the gr...

Embodiment 2

[0046] A method for manufacturing a space product fire extinguisher structure, comprising the following steps:

[0047] S1, set fire extinguishing holes on space products where fire extinguishing operations are required; fire extinguishing holes are set at positions where fire extinguishing operations are required, and astronaut Xu can quickly identify and reach this position;

[0048] S2, opening a groove on the electromagnetic shielding cloth 1, and pasting the electromagnetic shielding cloth 1 on the through hole of the fire extinguisher; first engraving a circular groove on the electromagnetic shielding cloth 1, and then setting it in the circular groove 12 Cross groove 11;

[0049] S3, paste the warning layer 2 on the electromagnetic shielding cloth 1, and the operation hole on the warning layer 2 exposes the groove on the electromagnetic shielding cloth 1.

[0050] The present embodiment also includes S4, sticking the fire extinguisher mark 3 around the electromagnetic ...

Embodiment 3

[0055] The space product of this embodiment includes a space product body and the fire extinguisher structure, and the space product body is provided with a through hole for the fire extinguisher.

[0056] In this embodiment, electromagnetic shielding cloth is used to achieve sealing, and at the same time, different laser drilling is used for electromagnetic shielding cloth to realize electromagnetic shielding, and at the same time, it can also quickly pierce the electromagnetic shielding cloth for fire extinguishing, and the warning ring and fire extinguishing port mark can remind personnel The position of the fire extinguisher can be quickly searched. In this embodiment, electromagnetic shielding cloth is pasted on the through hole of the fire extinguisher, so as to meet the requirement of operating efficiency under the condition of on-orbit microgravity under the condition of electromagnetic shielding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com