Modification method of activated carbon fiber material

A technology of activated carbon fiber and activated carbon fiber cloth, which is applied in the field of modification of activated carbon fiber materials, can solve problems such as insufficiency and achieve safe and gentle reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

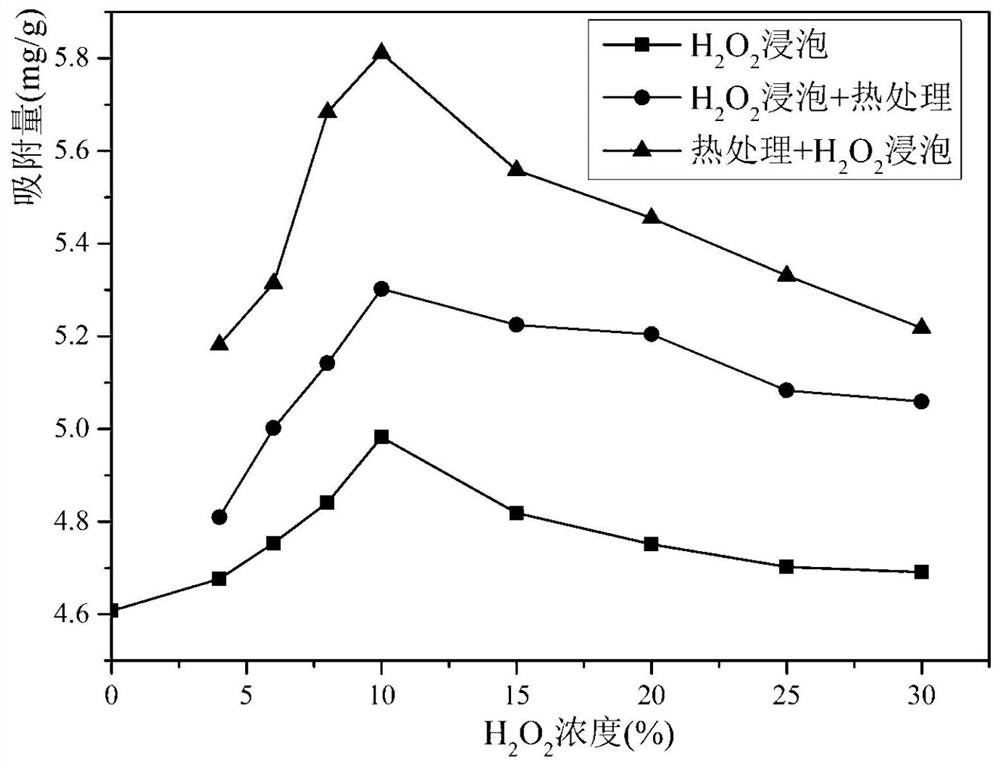

[0027] A method for modifying polyacrylonitrile-based activated carbon fibers, including soaking + heat treatment modification: cutting polyacrylonitrile-based activated carbon fiber cloth (hereinafter referred to as ACF) into about 2g / piece. Then the cut ACF was filled with 300ml of different concentrations (4%, 6%, 8%, 10%, 15%, 20%, 25%, 30%) of H 2 o 2 Immerse completely in a beaker for 24 hours. Then put the soaked ACF into a 100ml porcelain crucible with tweezers, place it in an oven for 4 hours at 120°C, and then adjust the oven to 200°C for heat treatment for 3 hours, take it out and cool it, and obtain the modified ACF material.

Embodiment 2

[0029] A method for modifying polyacrylonitrile-based activated carbon fibers, including heat treatment + soaking modification: cutting polyacrylonitrile-based activated carbon fiber cloth into about 2g / piece. Put the cut ACF into a 100ml porcelain crucible, heat it in an oven at 200°C for 3 hours, and take it out to cool. The ACF after the heat treatment is filled with 300 ml of H of different concentrations (4%, 6%, 8%, 10%, 15%, 20%, 25%, 30%) respectively. 2 o 2 After immersing in a beaker for 24 hours, place it in an oven for 4 hours at 120°C and then take it out to cool to obtain a modified ACF material.

Embodiment 3

[0031] The modified ACF material prepared in the above-mentioned Examples 1-2 was detected, and the results are shown in Table 1. When no modification treatment was performed, the ACF effect on SO 2 The adsorption capacity was 4.6076 mg / g. Through different concentrations of H 2 o 2 After immersion, ACF vs. SO 2 The adsorption capacity has been improved to a certain extent, in which 10% H 2 o 2 After soaking, the adsorption capacity increased the most, reaching 4.9819mg / g, which was 8.12% higher than that of the unmodified ACF original sheet. followed by H 2 o 2 When the concentration increases, the aggressiveness to the ACF material is too large, which makes the ACF structure unstable and collapses, resulting in ACF-SO 2 The adsorption capacity decreased gradually, when the H 2 o 2 When the concentration exceeds 20%, the promotion rate begins to decrease, so the preferred H 2 o 2 The concentration is 4%-20%.

[0032] Table 1 ACF-SO after composite modification in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com