In-situ quality comprehensive evaluation method for selective laser melting technology

A technology of laser selective melting and comprehensive evaluation, which is applied in the direction of additive manufacturing and additive processing, can solve the problems of inaccurate analysis results and long time consumption, and achieve the effects of multiple analysis methods, improved quality, and high analysis accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0101] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

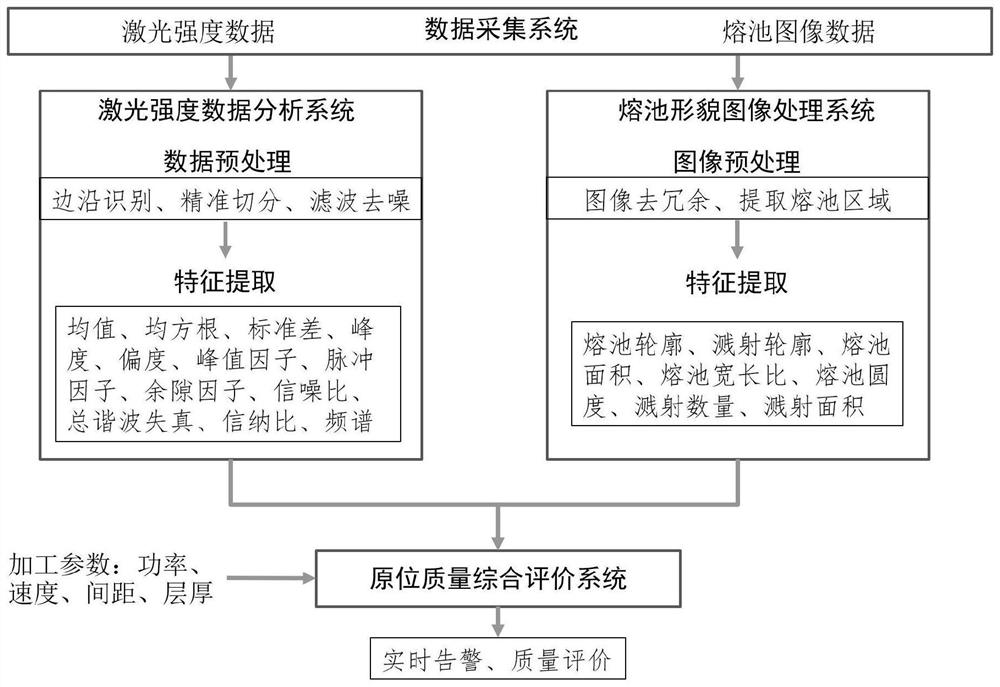

[0102] as attached figure 1 As shown, a method for comprehensive evaluation of in-situ quality of additive manufacturing, including the following steps, S1: collecting laser radiation intensity data and molten pool images during laser selective melting;

[0103] Specifically, silicon photodetectors are used to collect laser radiation intensity data during the selective laser melting process, and the melting pool image acquisition module uses a high-speed camera to collect real-time images of the molten pool during the selective laser melting process.

[0104] Further, step S2: using the laser radiation intensity data analysis system to analyze the laser radiation intensity data collected in step S1;

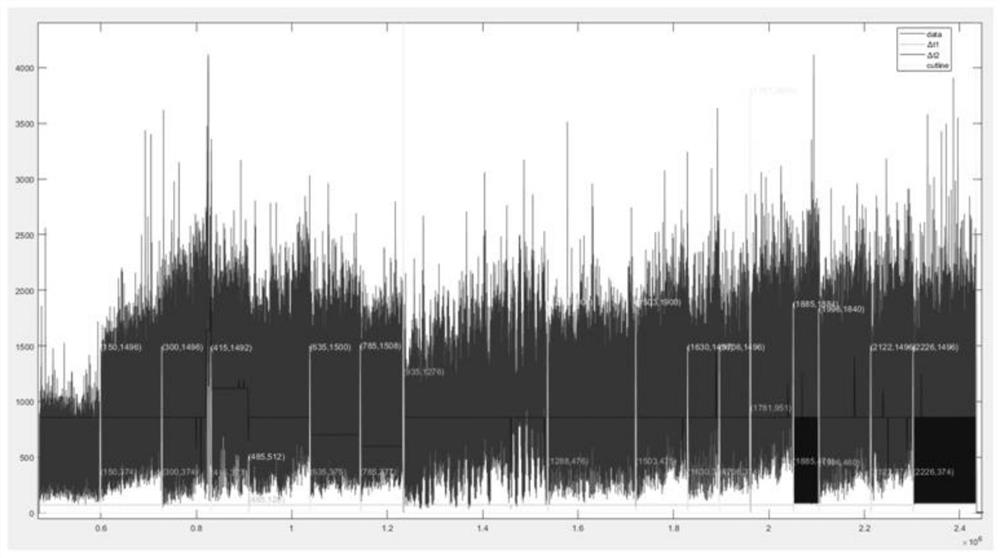

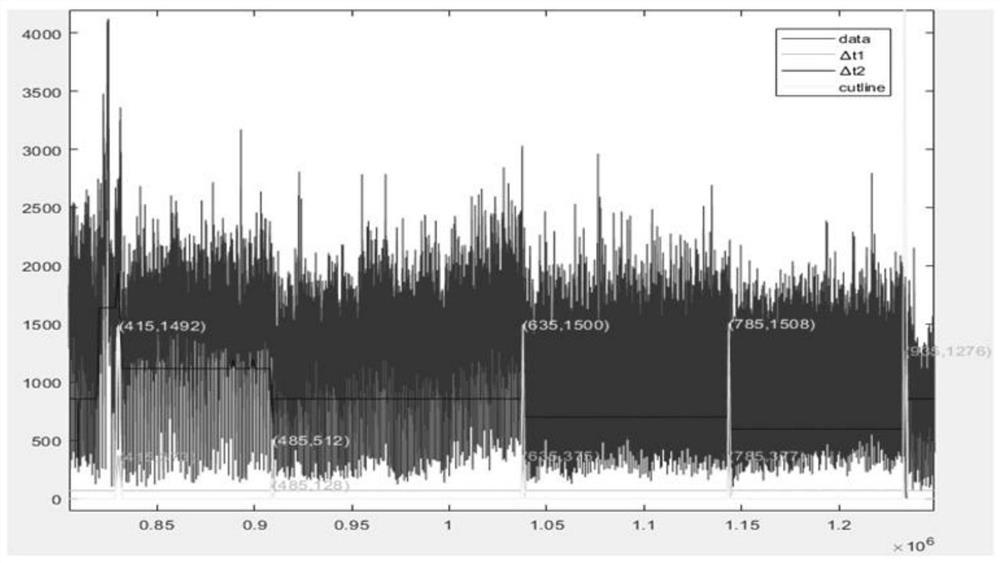

[0105] Specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com