Metal-based composite material and preparation method thereof

A composite material, metal-based technology, applied in metal processing equipment, manufacturing tools, welding equipment and other directions, can solve the problems of being susceptible to environmental pollution, low preparation efficiency, poor mechanical properties, etc., to achieve high bonding performance, improve service life, The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

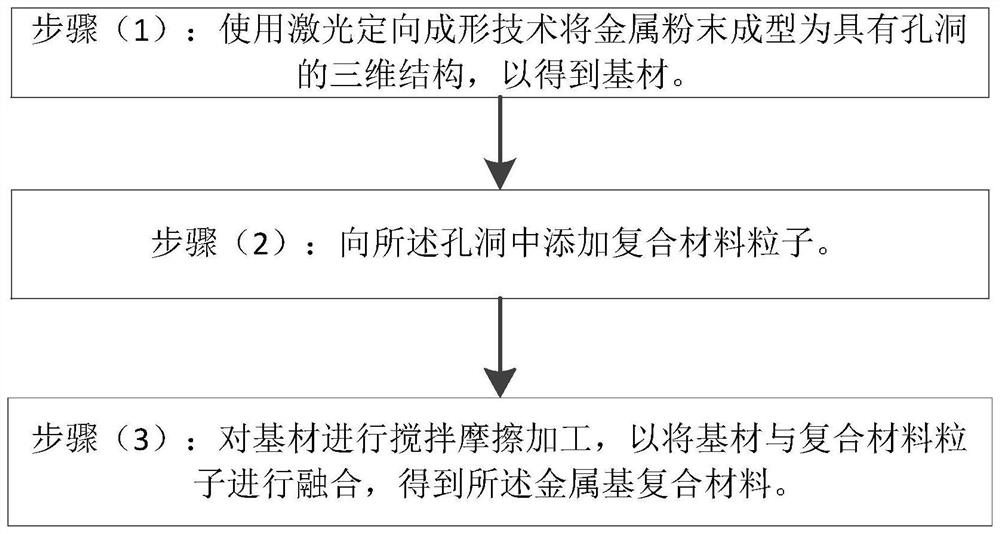

[0047] The metal matrix composites of Examples 1-6 were prepared using the following steps:

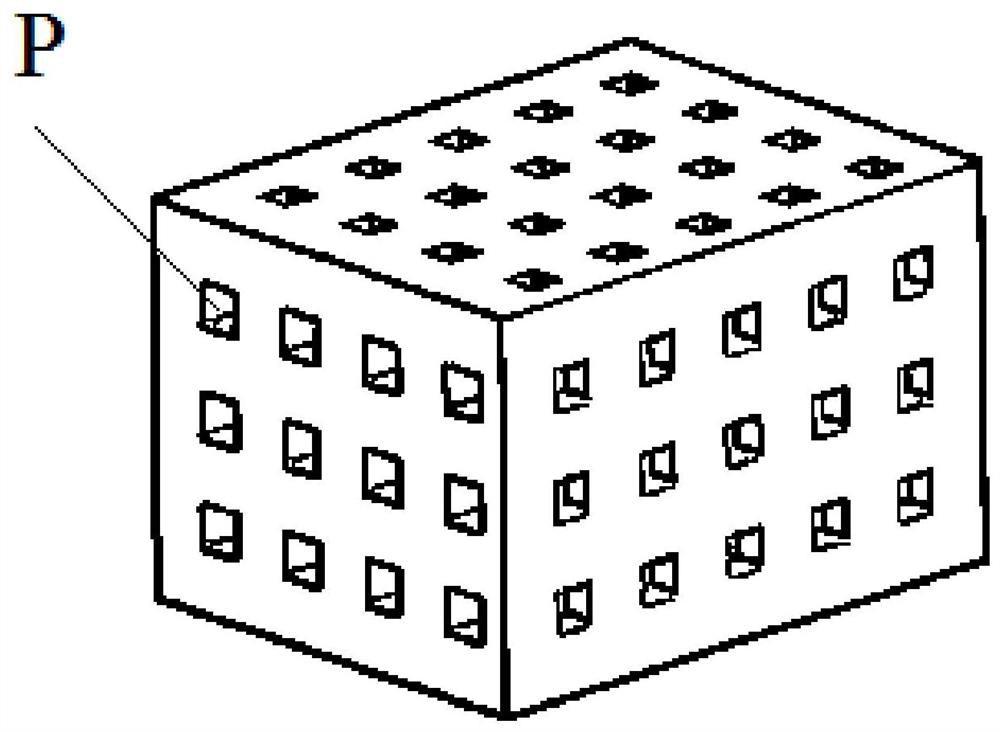

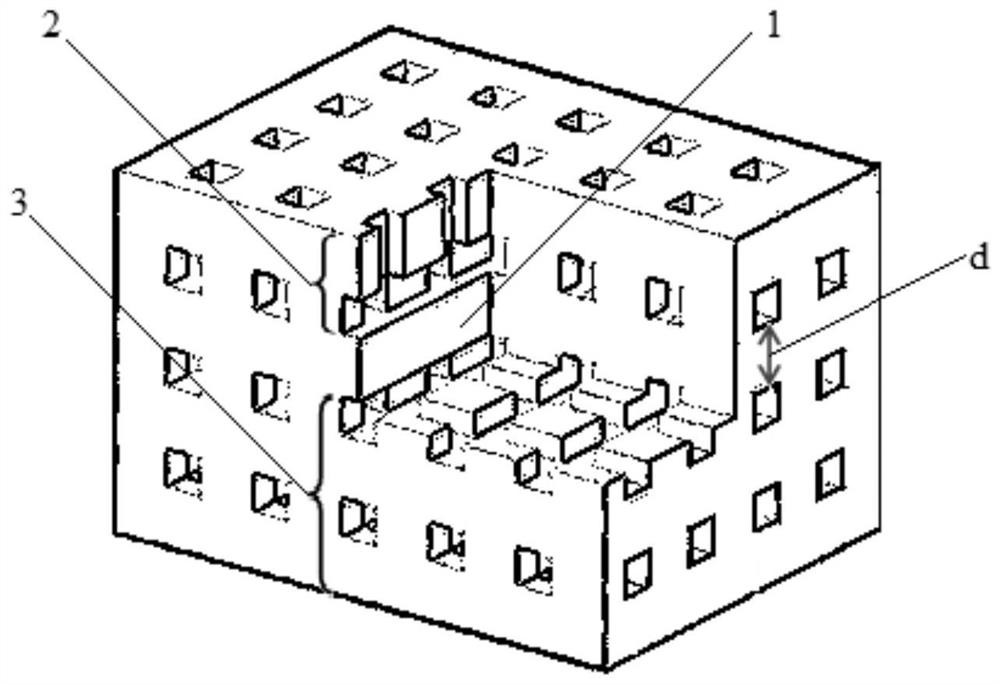

[0048] (1) Metal powder is formed into a substrate with holes by using laser directional forming technology, and the type of metal powder used can refer to Table 1. When performing laser directional forming technology to 3D print metal powder, the model structure can be designed first. For example, the length and width of the holes and the base material can be set first. The specific structure settings can refer to Table 2.

[0049] (2) Add composite material particles into the holes, the composite particles used can refer to Table 1.

[0050] (3) Friction stir processing is performed on the base material to fuse the base material and composite material particles to obtain a metal matrix composite material.

[0051] In addition, it should be noted that, in some embodiments, the substrate in this technical solution may be a three-dimensional structure uniformly distributed throughout. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com