Polymethoxy dimethyl ether production system and production method

A polymethoxydimethyl ether, production system technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problem of low effective components, low paraformaldehyde conversion rate, long reaction time, etc. problem to achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

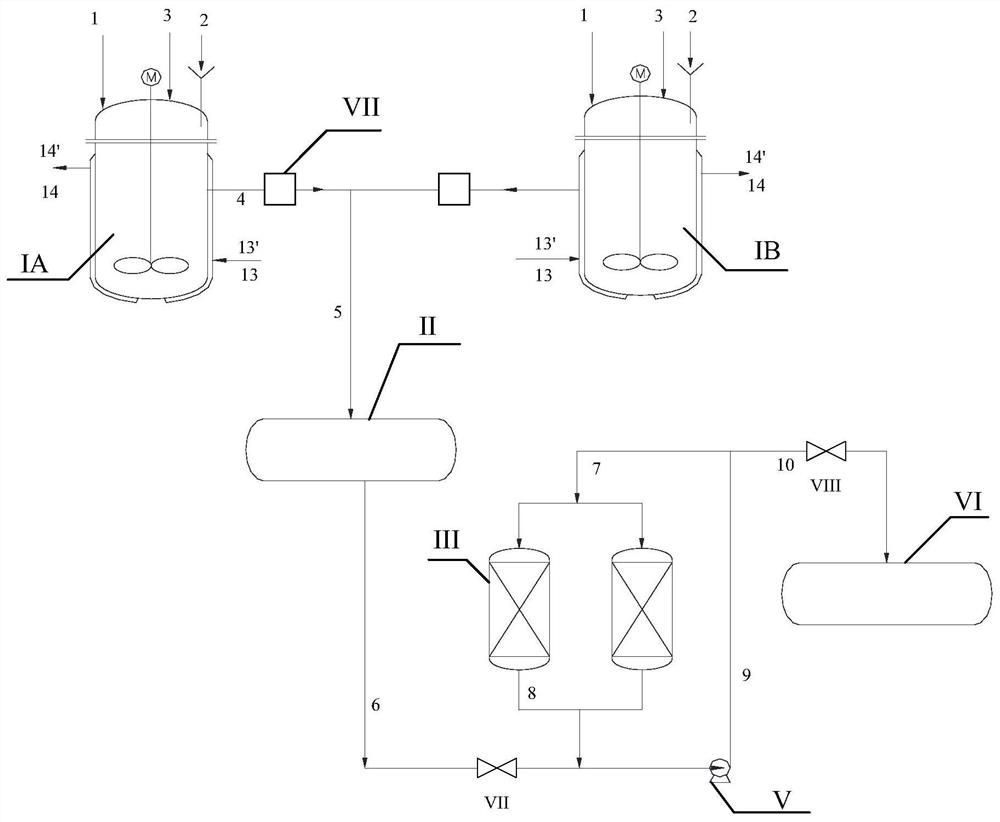

[0059] Step 1: 141kg paraformaldehyde (2) and 600kg methylal (1) are passed into a jacketed tank type stirred reactor (IA with a volume of 2 cubic meters, 140kg cationic resin catalyst is housed in it), through heat transfer oil ( 13) Feed control The reaction temperature is 100°C, the pressure is adjusted to 500kPa by nitrogen gas (3), and the first reaction solution (4) is prepared by stirring continuously for 0.5h at a rotation speed of 500r / min.

[0060] Step 2: remove the heat and cool down the first reaction liquid (4) through the heat transfer oil feed (13'), and when the temperature of the first reaction liquid (4) drops to 30°C, the first reaction liquid (4) is removed from the The outlet of the jacketed tank type stirred reactor (IA) (the discharge port is positioned at 60% of the height of the jacketed tank type stirred reactor) is discharged, and filtered through the filter (VII, the filter screen mesh number is 50) After the treatment, the second reaction solution...

Embodiment 2

[0066] Step 1: 160kg paraformaldehyde (2) and 650kg methylal (1) are passed into a jacketed tank type stirred reactor (IA with a volume of 2 cubic meters, 160kg cationic resin catalyst is housed in it), through heat transfer oil ( 13) Feed control The reaction temperature is 120°C, the pressure is adjusted to 600kPa by nitrogen gas (3), and the first reaction solution (4) is prepared by stirring continuously for 0.5h at a rotation speed of 500r / min.

[0067] Step 2: remove the heat and cool down the first reaction liquid (4) through the heat transfer oil feed (13'), and when the temperature of the first reaction liquid (4) drops to 40°C, the first reaction liquid (4) is removed from the The outlet of the jacketed tank type stirred reactor (IA) (the discharge port is located at the 55% height of the jacketed tank type stirred reactor) is discharged, and filtered through the filter (VII, the filter screen mesh number is 80) After the treatment, the second reaction solution (5) i...

Embodiment 3

[0073] Polyoxymethylene dimethyl ether was produced in the manner in Example 2, except that the outlet of the jacketed tank stirred reactor (IA) was located at 45% of the height of the jacketed tank stirred reactor.

[0074] The result shows that the conversion rate of paraformaldehyde is 89%, and PODE in the fourth reaction liquid (10) 3-4 The content is 17%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com