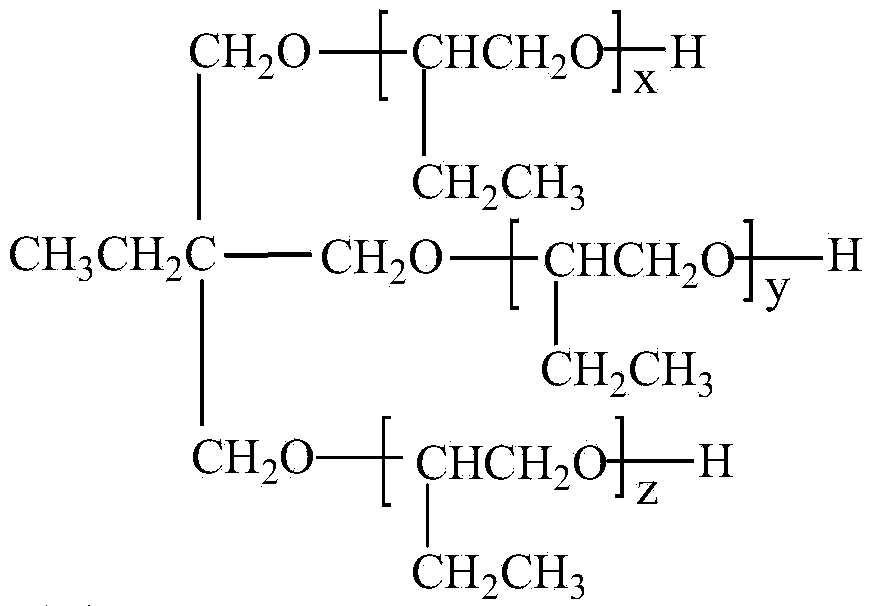

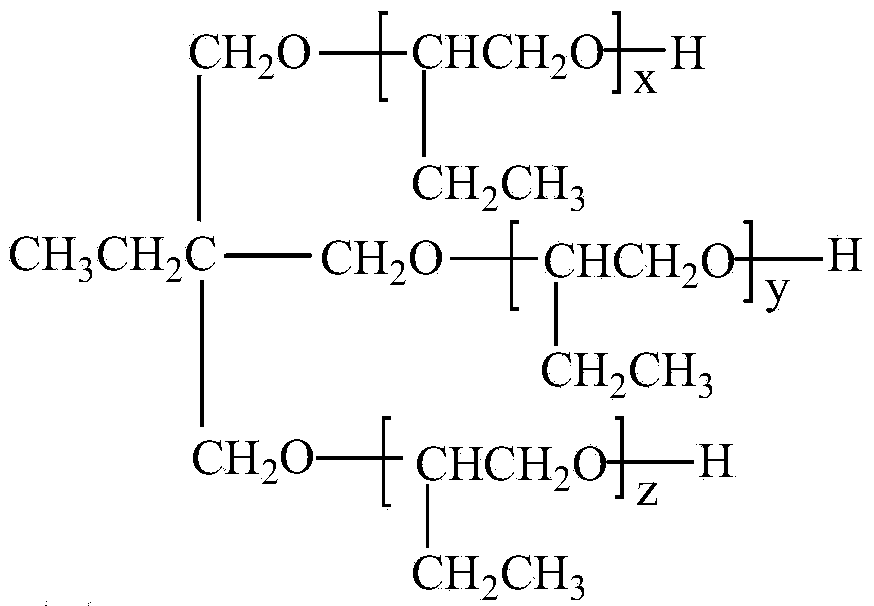

Synthetic method of trimethylolpropane polyoxy butylene ether

A technology of trimethylolpropane polyoxybutene ether and methylolpropane polyoxybutene ether, which is applied in the synthesis field of trimethylolpropane polyoxybutene ether and achieves good performance, stable quality and advanced technology reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Add 671.0 parts by weight of trimethylolpropane to the reaction kettle, add 0.88 parts by weight of sodium hydroxide, replace the air in the kettle with nitrogen for three times, then raise the temperature to 110-115°C, and under the vacuum degree ≥ -0.095MPa, heat preservation and dehydration for 40 minutes, add 1081.5 parts by weight of butylene oxide to react, the reaction time is 4.5 hours, the reaction temperature is 100-105°C, after the reaction is completed, the temperature is lowered to 60°C, and the crude trimethylolpropane polyoxybutylene ether is moved to 3L In the four-neck flask, add 61.4 parts by weight of water and stir for 30 minutes, neutralize with phosphoric acid, add 8.8 parts by weight of magnesium silicate polyether refined adsorbent, the adsorption temperature is 60 ° C ~ 70 ° C, the time is 30 minutes, and then the temperature is raised to 110~115°C, under vacuum ≥-0.097MPa, heat preservation and dehydration for 1.5 hours, then lower the temperatu...

Embodiment 2

[0024] Add 268.4 parts by weight of trimethylolpropane to the reaction kettle, add 1.71 parts by weight of potassium hydroxide, replace the air in the kettle with nitrogen for three times, then raise the temperature to 110-115°C, and under the vacuum degree ≥ -0.095MPa, heat preservation and dehydration for 50 minutes, add 1431.6 parts by weight of butylene oxide to react, the reaction time is 7.0 hours, the reaction temperature is 110-115°C, after the reaction is completed, the temperature is lowered to 60°C, and the crude trimethylolpropane polyoxybutylene ether is moved to 3L In the four-neck flask, add 102.6 parts by weight of water and stir for 30 minutes, neutralize with phosphoric acid, add 17.0 parts by weight of aluminum silicate polyether refined adsorbent, the adsorption temperature is 60 ° C ~ 70 ° C, the time is 30 minutes, and then the temperature is raised to 110~115°C, under vacuum ≥-0.097MPa, heat preservation and dehydration for 1.5 hours, then lower the tempe...

Embodiment 3

[0029] Add 187.9 parts by weight of trimethylolpropane to the reaction kettle, add 3.07 parts by weight of sodium methoxide, replace the air in the kettle with nitrogen three times, then raise the temperature to 115-120°C, and keep the temperature for dehydration for 60 minutes at a vacuum degree ≥ -0.095MPa , adding 1492.3 parts by weight of butylene oxide to react, the reaction time is 9.0 hours, the reaction temperature is 110-115°C, after the reaction is completed, the temperature is lowered to 60°C, and the crude trimethylolpropane polyoxybutylene ether is moved to 3L four Add 136.2 parts by weight of water and stir for 30 minutes, neutralize with phosphoric acid, add 12.6 parts by weight of refined magnesium silicate polyether adsorbent, 12.6 parts by weight of refined aluminum silicate polyether adsorbent, and the adsorption temperature is 60 °C ~70°C for 40 minutes, then heat up to 110~115°C, in a vacuum ≥ -0.097MPa, heat preservation and dehydration for 2.0 hours, then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com