Settling separation method for nickel leaching solution

A technology of sedimentation separation and leaching liquid, applied in the direction of improving process efficiency, can solve the problems such as the decline of extraction production capacity, the increase of the third phase in the extraction process, the increase of production costs, etc., to prevent the loss of valuable metal materials, reduce production costs, The effect of increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

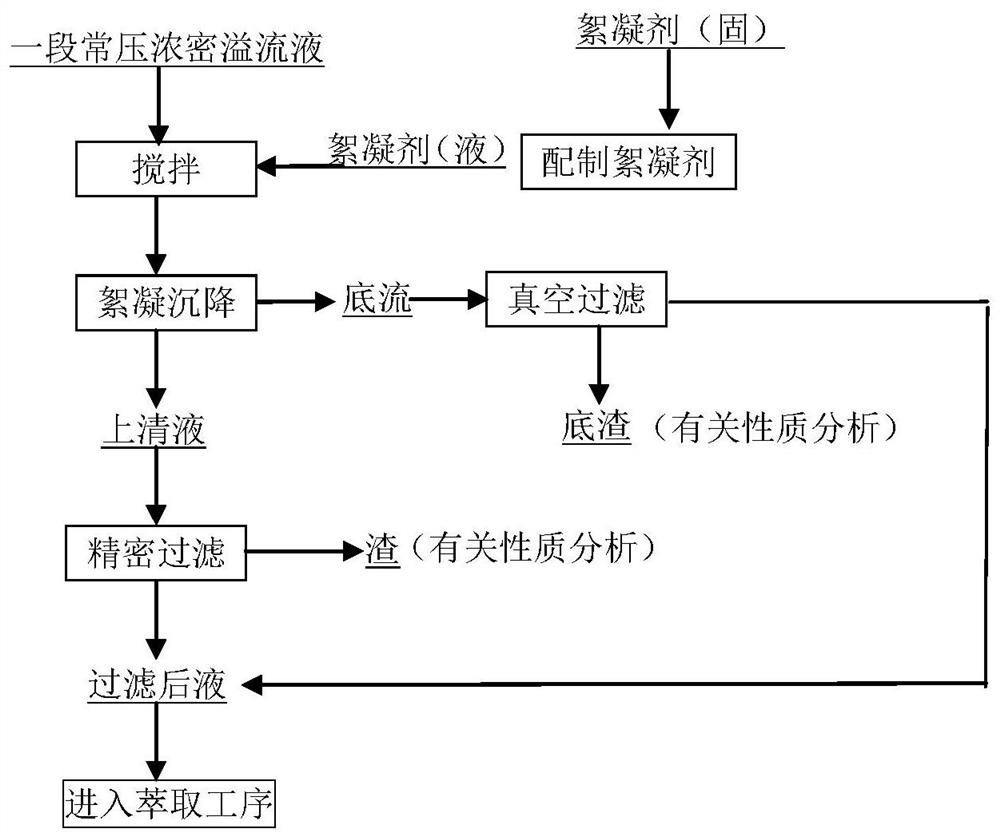

[0023] Laboratory flocculation sedimentation test, process flow see attached figure 1 .

[0024] Take a 200L section of normal pressure leaching thickener overflow liquid for laboratory flocculation and sedimentation test. The test was carried out in a mud bucket with a height of 1.4m and a diameter of 0.35m. A peristaltic pump was used to continuously feed (overflow liquid), the feeding rate was 1L / min, the flow rate of 1‰ flocculant was 6mL / min, and the flocculation and sedimentation supernatant was collected continuously. Filter the flocculation supernatant with a vacuum filter. The filtered solution was subjected to extraction test. Test results: The solid content of the flocculation supernatant is 0.35g / L (about 0.026%), and the solid content is reduced by 94.60% compared with the overflow liquid of the on-site thickener (the on-site solid content is 6.5-7.0g / L). After the flocculation supernatant is filtered The liquid is clear and free of particles. The extraction ...

Embodiment 2

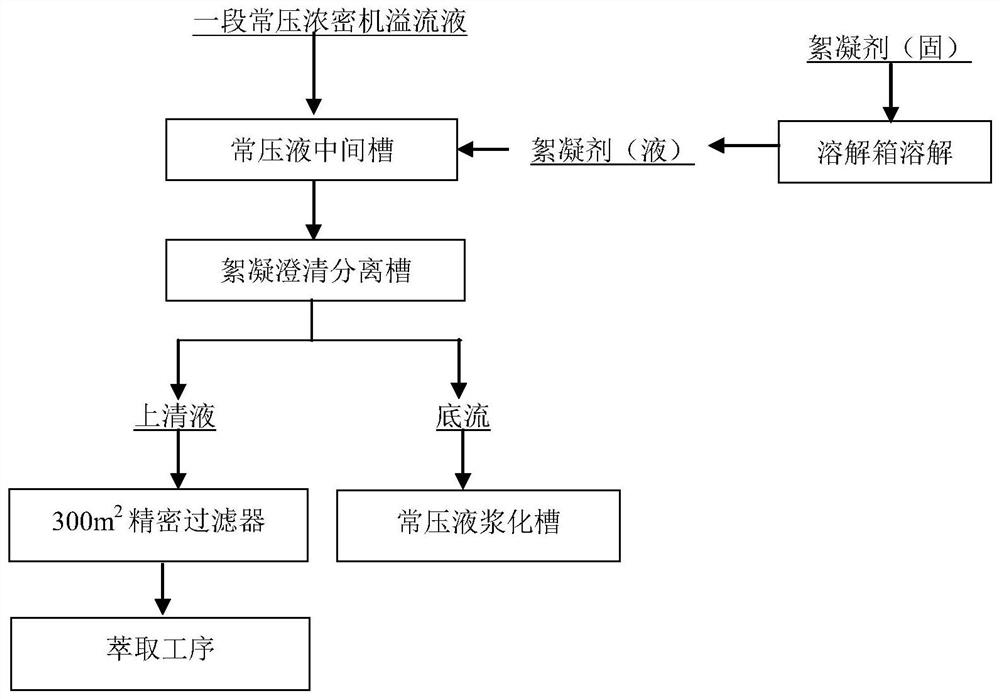

[0026] On-site industrial small-scale test, the process flow is attached figure 2 .

[0027] Using the existing equipment on site to carry out transformation, part of a section of normal pressure leachate overflow (5m 3 / h) into 10m through the pipe 3 In the normal pressure intermediate tank, at the same time, add PAM-800 flocculant into the dissolution tank at a rate of 30g / h, and open the air duct and heating return pipe to dissolve the flocculant. After the dissolution is complete, open the valve and inject the flocculant into 10m 3 In the normal pressure intermediate tank, the flocculation reaction time is 5 to 10 minutes. Then pump in 6m through the solution transfer pump 3 Dense sedimentation separation is carried out in the clarification separation tank. The supernatant was returned to 300m 2 The precision filter is filtered, and the flocculation bottom flow is returned to the normal pressure liquid slurry tank. After 20 minutes of sedimentation and clarificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com