Lossless connection method and connection structure for sleeving of composite material pipe body and flange

A composite material pipe and connection method technology, which is applied in the field of non-destructive connection method and connection structure of composite material pipe body and flange socket connection, can solve the problems of low product connection reliability, uneven thickness of adhesive layer, tooling cost consumption, etc. , to achieve the effect of improving resin filling efficiency and consistency, uniform thickness, and improving load transfer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

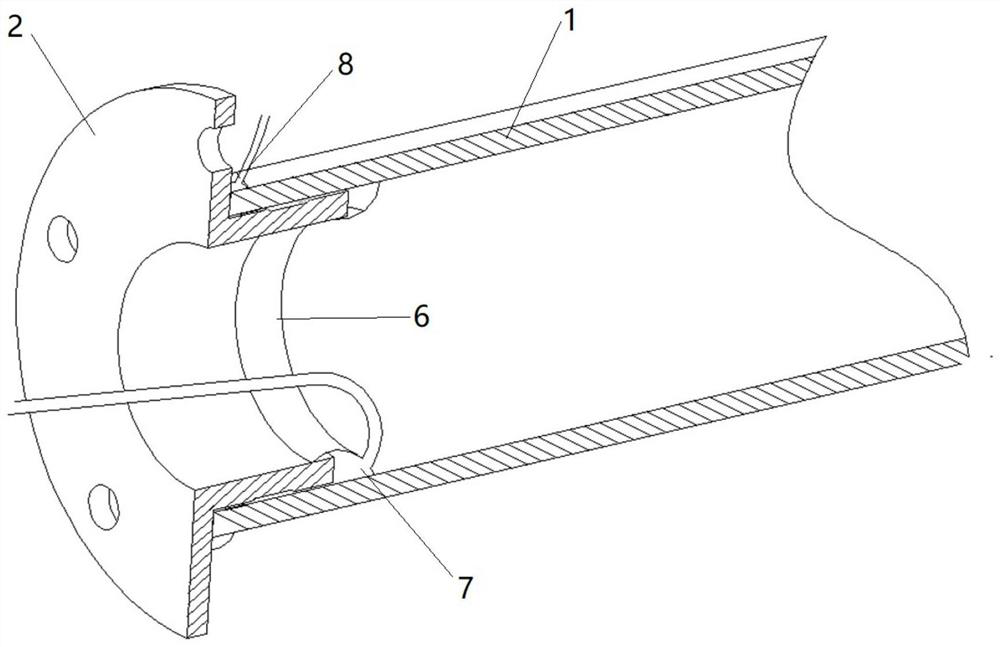

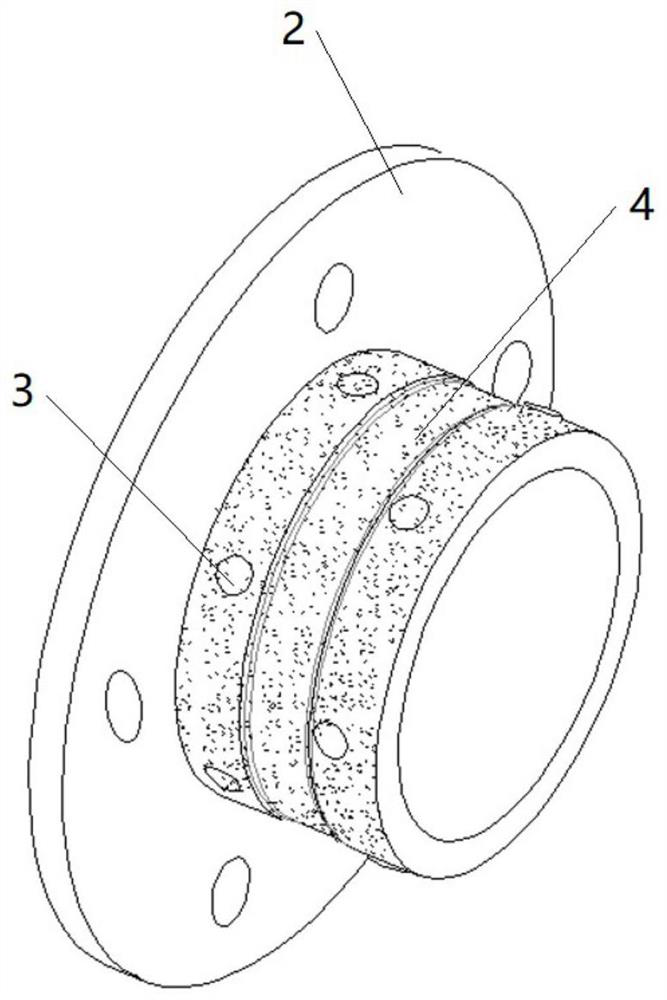

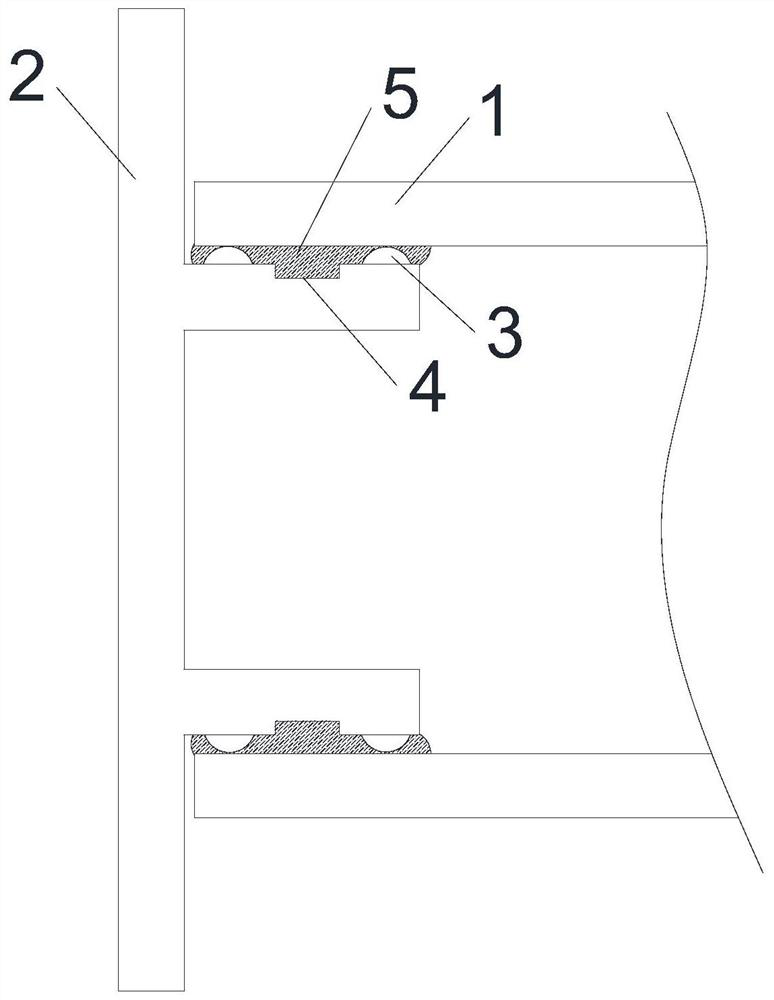

[0058] combined with figure 1 , figure 2 , image 3 As shown, a non-destructive connection method for a composite material pipe body and a flange socket described in this embodiment includes the following steps:

[0059] S0. Sand blast or sandpaper the surface of the socket area of the flange, and use sandpaper to polish the socket area of the composite pipe body to a matte surface, and then use acetone or ethanol to clean the socket area. cleaning;

[0060] S1. On the socket surface of the flange, at both ends of the socket area, a round of raised parts 3 are respectively provided, and the raised parts of the circle are processed by 8 pieces with a height of 0.2 at equal intervals along the circumference of the flange's socket surface. mm spherical crown convex part, on the socket surface of the flange, an annular groove with a depth of 0.1mm is processed in the middle of the two-week raised part;

[0061] S2. Use tooling to socket the flange 2 and the composite mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com