Vacuum hot-pressing sintering preparation method for zinc-based composite material

A technology of vacuum hot pressing sintering and composite materials, which is applied in the field of preparation of medical degradable metal materials, can solve the problems of not being able to meet the production needs of medical degradable zinc-based composite materials, poor mechanical properties of zinc alloys, and coarse grains, etc., to achieve The effect of protecting structural integrity, ensuring quality, and compacting tissue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1. A method for preparing a zinc-based composite material by vacuum hot pressing and sintering, specifically comprising the following steps:

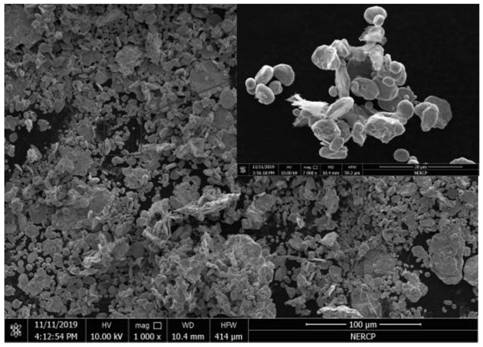

[0026] (1) Choose zinc powder with an average diameter of 5um and a specific surface area of 50-200m 2 / g, graphene powder with a thickness of 1-3 layers (0.686nm-1.054nm);

[0027] (2) The specific process parameters of variable speed ball mill mixing are: 150r / min ball mill for 3h, 280r / min ball mill for 1.5h, 300r / min ball mill for 0.5h;

[0028] (3) The uniformly mixed dry powder is hot-pressed and sintered in a vacuum hot-pressed sintering furnace to obtain a graphene-reinforced zinc-based composite material block. The specific sintering parameters are: the heating rate is 10°C / min, and the sintering temperature is 380°C. The sintering pressure is 30MPa, and the sintering time is 30min. After the sintering is completed, the power is turned off and the furnace cools down.

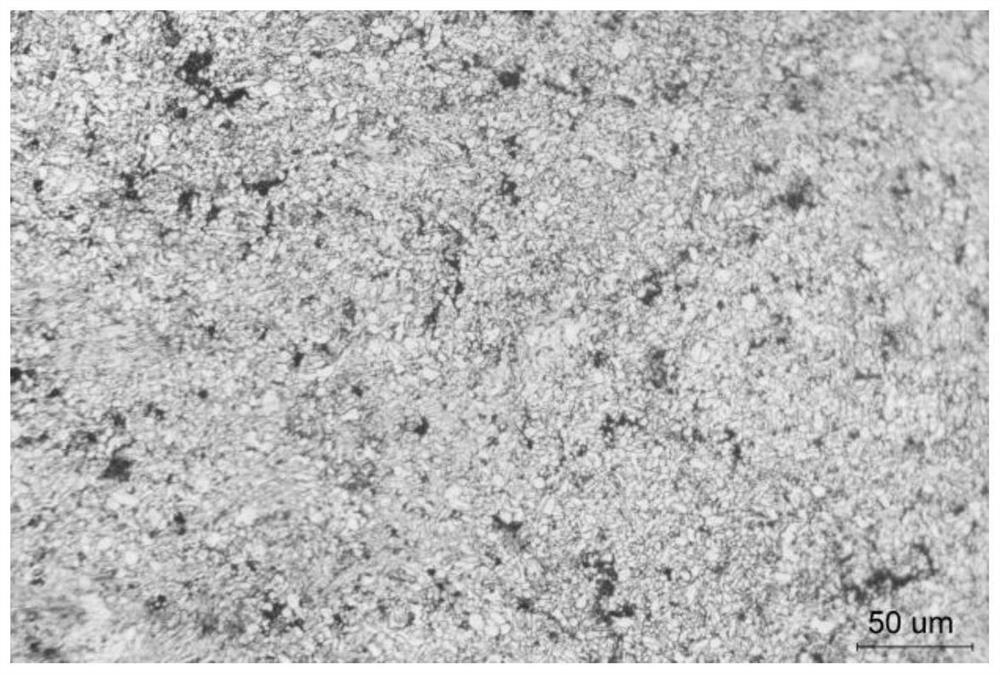

[0029] The surface of the zinc-based co...

Embodiment 2

[0030] Example 2. A preparation method for vacuum hot pressing and sintering of zinc-based composite materials,

[0031] The difference from Example 1 is that the powder material used in this example is a three-component material of zinc, magnesium, and calcium, and the Zn-Mg-Ca alloy material is prepared by the vacuum hot-pressing sintering method described in the present invention.

[0032] The specific steps of the method are: (1) selecting the average diameter of the alloy powder to be 10um;

[0033](2) The specific process parameters of the variable speed ball milling mixture are: 150r / min for 3h, 280r / min for 1.5h, and 300r / mim for 0.5h;

[0034] (3) The uniformly mixed dry powder is hot-pressed and sintered in a vacuum hot-pressing sintering furnace to obtain a zinc-based composite material block. The specific sintering parameters are: the heating rate is 15°C / min, the sintering temperature is 390°C, and the sintering pressure is 35MPa , The sintering time is 45min. A...

Embodiment 3

[0036] Example 3. A method for preparing a zinc-based composite material by vacuum hot pressing sintering, specifically comprising the following steps:

[0037] (1) Choose zinc powder with an average diameter of 5um and a specific surface area of 50-200m 2 / g, graphene powder with a thickness of 1-3 layers (0.686nm-1.054nm);

[0038] (2) The specific process parameters of the variable-speed ball milling mixture are: ball milling at 140r / min for 2.8h, 275r / min for 1.4h, and 290r / mim for 0.4h;

[0039] (3) The uniformly mixed dry powder is hot-pressed and sintered in a vacuum hot-pressing sintering furnace to obtain a graphene-reinforced zinc-based composite material block. The specific sintering parameters are: heating rate of 10°C / min, 2×10 -2 Pa, the sintering temperature is 360°C, the sintering pressure is 30MPa, the sintering time is 30min, and the furnace is cooled after the sintering is completed.

[0040] The zinc-based composite material obtained in this example ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com