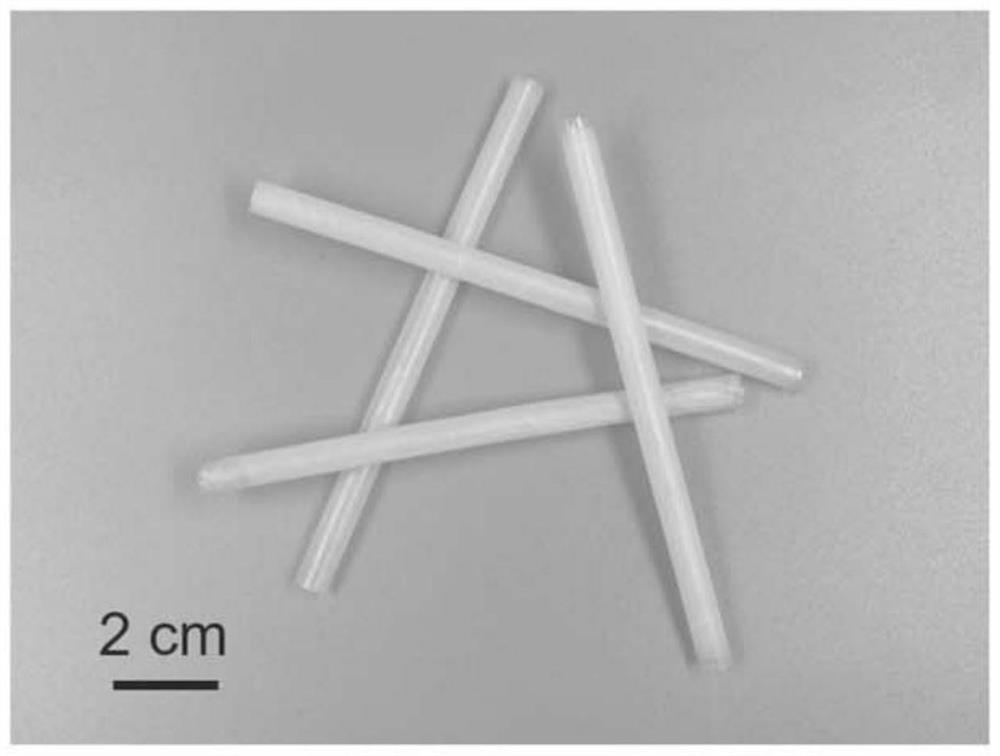

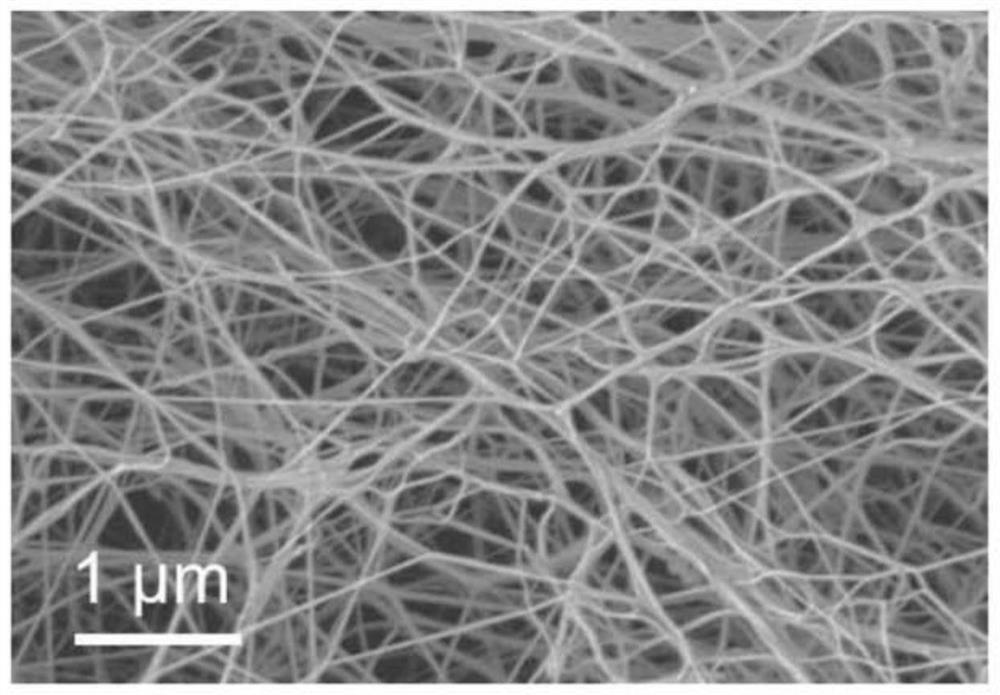

Bacterial cellulose-based edible straw and preparation method thereof

A bacterial cellulose and straw technology, which is applied to the field of bacterial cellulose-based edible straws and their preparation, can solve problems such as negative effects and hinder the growth of animals and plants, and achieve the effects of excellent water resistance and structural integrity that will not be destroyed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] On the other hand, the application also provides a preparation method of bacterial cellulose-based edible straws, comprising the following steps:

[0043] A) Prepared by 10-100g L -1 Glucose, 1-40g L -1 Yeast extract, 0.1-10g L -1 Citric acid, 0.1-10gL -1 Na 2 HPO 4 12H 2 O and 0.1-10g L -1 K H 2 PO 4 The composed liquid culture medium is then sterilized at 110-150° C., preferably 120° C., for 5-90 minutes in a sterilizing pot. After sterilization, bacterial cellulose-producing bacteria are inoculated into the culture medium. After continuous fermentation for about four days at a constant temperature of 25-30° C., a bacterial cellulose hydrogel with a desired thickness of, for example, 2-10 mm, preferably about 5 mm is obtained;

[0044] B) treating the bacterial cellulose hydrogel biosynthesized in step A) in an aqueous hydrogen peroxide solution with a mass fraction of 0-50%, removing impurities and bleaching;

[0045] C) drying the hydrogel obtained in ste...

Embodiment 1

[0067] A) firstly prepare by 50g L -1 Glucose, 5g L -1 Yeast extract, 2g L -1 Citric acid, 4g L -1 Na 2 HPO 4 12H 2 O and 2g L -1 K H 2 PO 4 The composed liquid medium was then sterilized at 120°C for 30 minutes in a sterilizer. After sterilization, inoculate Acetobacter xylinum (CGMCC 1.1812, purchased from China General Microorganism Culture Collection and Management Center) into the medium, and ferment continuously for about four days at a constant temperature of 25-30°C to obtain bacterial fibers with a thickness of about 5mm plain hydrogel;

[0068] B) treating the bacterial cellulose hydrogel in step A) in an aqueous hydrogen peroxide solution with a mass fraction of 3%, removing impurities and bleaching;

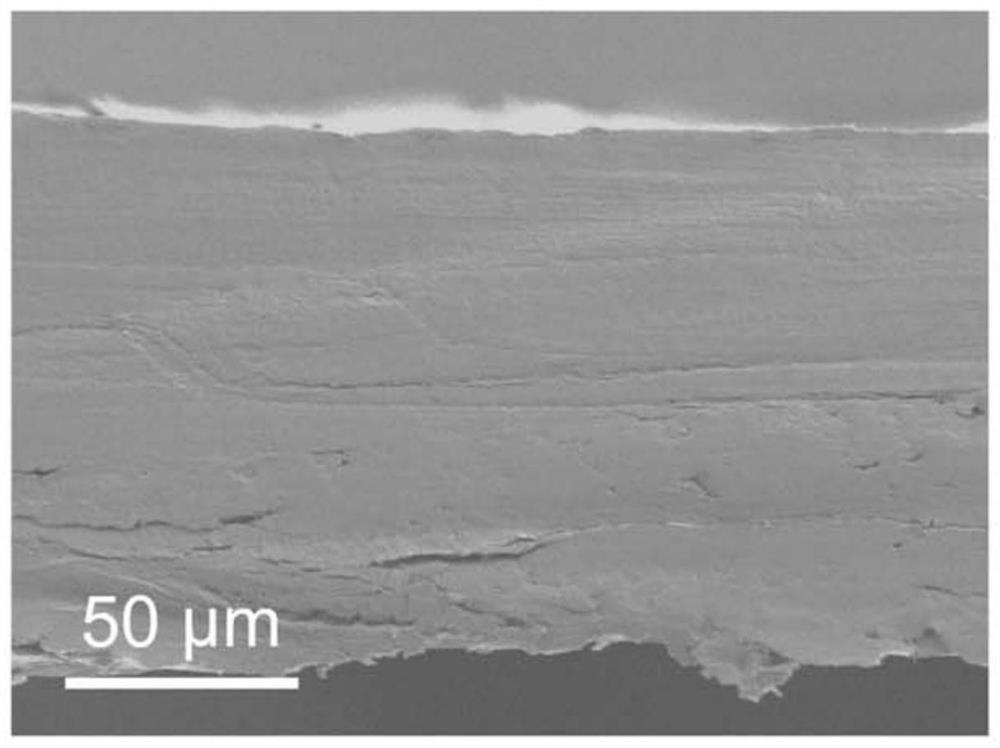

[0069] C) drying the hydrogel obtained in step B) to form a film at 60° C. under a temperature and pressure of 1 MPa to obtain a bacterial cellulose film;

[0070] D) in step C) the bacterial cellulose film surface that obtains is coated with a layer of sod...

Embodiment 2

[0084] A) firstly prepare by 50g L -1 Glucose, 5g L -1 Yeast extract, 2g L -1 Citric acid, 4g L -1 Na 2 HPO 4 12H 2 O and 2g L -1 K H 2 PO 4 The composed liquid medium was then sterilized at 120°C for 30 minutes in a sterilizer. After sterilization, inoculate the culture medium with Acetobacter xylinum (CGMCC 1.1812, purchased from China General Microorganism Culture Collection and Management Center), and ferment continuously for about four days at a constant temperature of 25-30°C to obtain bacteria with a thickness of about 5mm Cellulose hydrogel;

[0085] B) The bacterial cellulose hydrogel in step A) is treated in a 3% hydrogen peroxide aqueous solution to remove impurities and bleach, and then soaked in a commercially available edible coloring solution for 5 hours to make the pigment molecules Fully penetrate into the three-dimensional network of bacterial cellulose;

[0086] C) drying the hydrogel obtained in step B) to form a film at 30° C. under a temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com