Vertical three-dimensional nano gas sensor with micro heater and preparation method thereof

A gas sensor, three-dimensional nanotechnology, applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of poor selectivity, high power consumption, etc., and achieve the effects of reducing heat loss, high specific surface area, and reducing operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

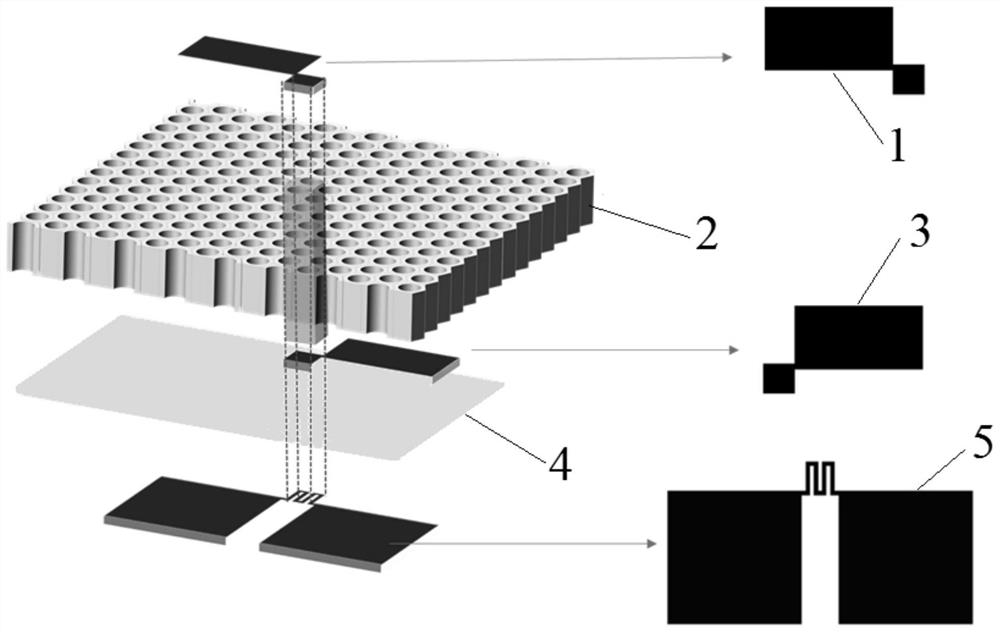

[0036] This embodiment provides a vertical three-dimensional nano-gas sensor with a micro-heater, the vertical nano-gas sensor includes: a housing and a heating-type gas sensing component packaged inside the housing, wherein the housing is preferably For the ceramic shell. see figure 1 , the heating type gas sensing component includes: up and down through-hole nanotubes 2, sensing electrodes, an insulating layer 4 and a micro heater 5.

[0037] Nanoscale gas-sensing materials are deposited on the inner wall of the upper and lower through-hole nanotubes 2, wherein the nanotubes 2 are preferably anodized aluminum nanotubes, the height is preferably 100nm-100μm, and the pore size is preferably 100nm-1μm; the gas-sensing material is preferably SnO 2 , of course, in other embodiments, the gas sensitive material can also choose TiO 2 , ZnO and other metal oxides. The sensing electrodes include a top sensing electrode 1 grown on the upper surface of the upper and lower through-ho...

Embodiment 2

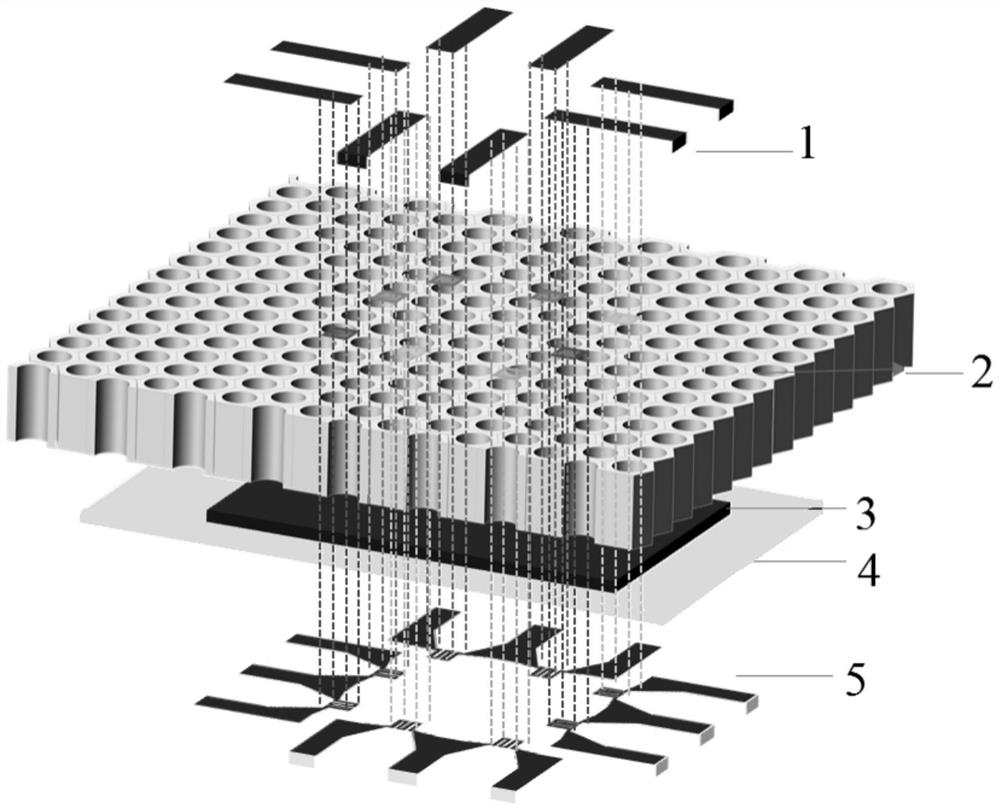

[0042] see figure 2 , this embodiment provides an array-type nano-gas sensor, the array-type nano-gas sensor includes a housing and a plurality of sets of heating-type gas sensing components described in Embodiment 1 packaged inside the housing, for future use Smart gas sensor arrays with machine learning algorithms provide the solution. figure 2 Eight nanometer gas sensors are integrated on a single chip.

Embodiment 3

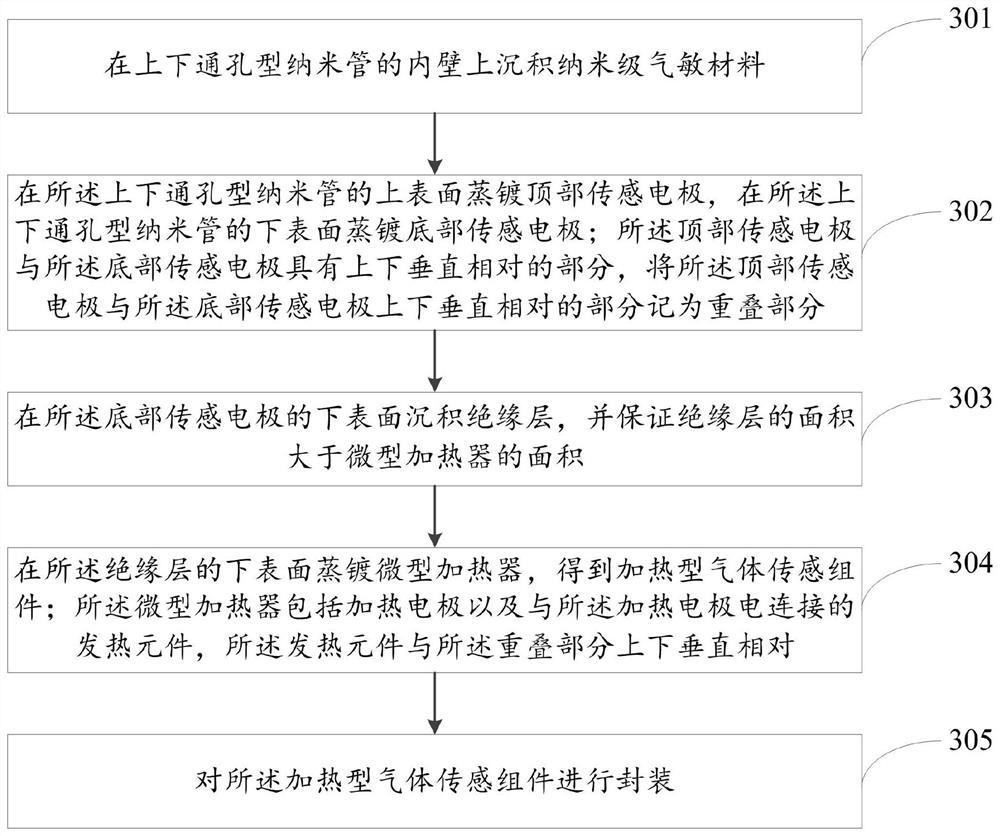

[0044] see image 3 , the present embodiment provides a method for preparing a vertical three-dimensional nano gas sensor with a micro heater in embodiment 1 and embodiment 2, the method includes the following steps:

[0045]Step 301: Deposit nanoscale gas-sensing material on the inner wall of the up-and-down through-hole nanotube.

[0046] A specific cycle process can be as follows:

[0047] Use tetradimethylaminotin as the tin source, open the ALD tin source valve for 300ms, close the tin source pump valve, the tin source stays in the cavity for 30s, open the nitrogen pump valve to clean the cavity for 30s; open the ALD gaseous water source valve for 30ms, and close the gaseous water source Pump valve, gaseous water stays in the cavity for 30s, open the nitrogen pump valve to clean the cavity for 5s. SnO grown within such a cycle 2 The thickness is about 0.1 nm. 3-15nm SnO obtained through multiple cycles 2 After thin film, high temperature calcination in air.

[0048]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com