Rapid detection method for heavy metals in water

A detection method and heavy metal technology, applied in measuring devices, instruments, material analysis through electromagnetic means, etc., to achieve good reproducibility, avoid the use of mercury, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0031] On-the-spot determination of heavy metal cadmium in embodiment 2 water samples

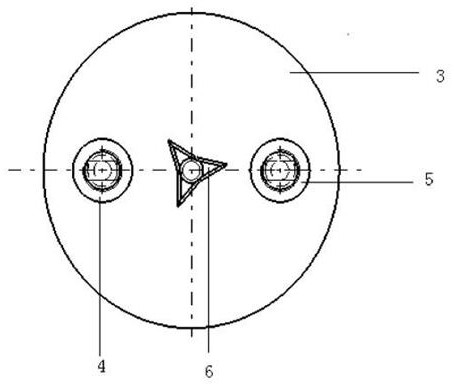

[0032] Step 1. Prepare a high-performance working electrode: put 5g of superconducting carbon black and 3g of ionic liquid N-hexylpyridine tetrafluoroborate into a stainless steel mortar, mechanically grind for 120 minutes under the protection of nitrogen and mix well, then put the mixture into Five internally threaded polytetrafluoroethylene tubes with an inner diameter of 10mm are compacted and formed, and the rear end of the externally threaded copper column is used as a wire. The structure is as follows figure 1 shown. Smooth on weighing paper before use. Twist the copper column, extrude the paste about 0.5mm and smooth it to renew.

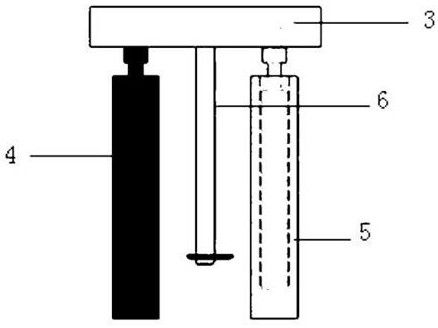

[0033] Step 2. Assemble the three-electrode system sensor and connect it to a portable electrochemical analyzer: figure 2 , 3 As shown, the sensor includes a counter electrode, a reference electrode, a fixed plate 3 and a working electrode 5. In order...

Embodiment 3

[0038] On-site determination of heavy metal copper in embodiment 3 water samples

[0039] Step 1. Prepare a high-performance working electrode: put 5g of conductive carbon black and 3.2g of ionic liquid N-hexylpyridine nitrate into a ceramic mortar, mechanically grind for 120 minutes under the protection of nitrogen and mix well, and then put the mixture into 5 inner diameters 6mm internal threaded polytetrafluoroethylene tube, compacted and formed, the rear end of the external threaded copper column is the wire, the structure is as follows figure 1 shown. Smooth on weighing paper before use. Twist the copper column, extrude the paste about 0.5mm and smooth it to renew.

[0040] Step 2. Assemble the three-electrode system sensor and connect it to a portable electrochemical analyzer: figure 2 , 3 As shown, the sensor includes a counter electrode, a reference electrode, a fixed plate 3 and a working electrode 5. In order to shorten the detection time, a polytetrafluoroethyl...

Embodiment 4

[0045] On-the-spot determination of heavy metal zinc in embodiment 4 water sample

[0046] Step 1. Preparation of a high-performance working electrode: 5 g of conductive carbon black and 4 g of ionic liquid N-octylpyridine tetrafluoroborate were placed in a polytetrafluoroethylene mortar, mechanically ground for 120 minutes under nitrogen protection, and then mixed The mixture is put into five internally threaded resin tubes with an inner diameter of 6mm, compacted and formed, and the rear end of the externally threaded copper column is used as a wire. The structure is as follows: figure 1 shown. Smooth on weighing paper before use. Twist the copper column, extrude the paste about 0.5mm and smooth it to renew.

[0047] Step 2. Assemble the three-electrode system sensor and connect it to a portable electrochemical analyzer: the sensor includes a counter electrode, a reference electrode, a fixed plate and a working electrode, and the platinum column counter electrode, Ag / AgCl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com