Mask alignment system, mask alignment method and lithographic equipment

A mask alignment and mask technology, applied in the field of lithography equipment and processes, can solve the problems of small measurement range, limited types of alignment marks, etc., and achieve the effect of strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

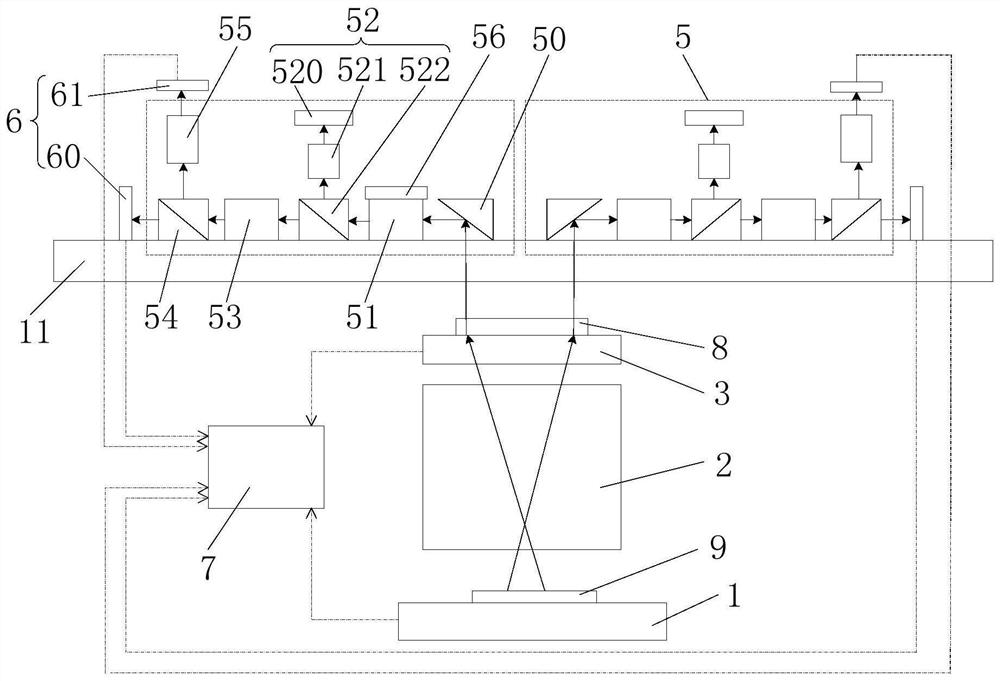

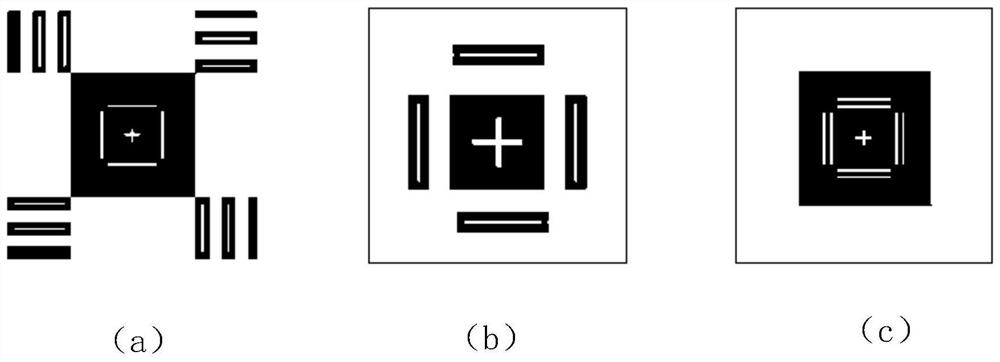

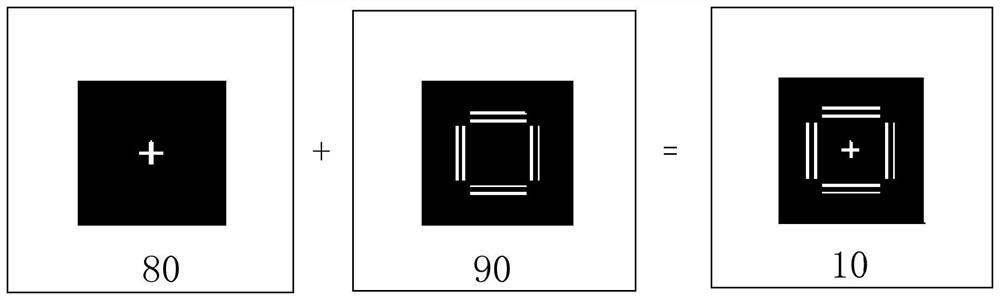

[0071] see Figure 1 to Figure 3 As shown, this embodiment provides a mask alignment system; figure 1 A schematic structural diagram of the mask alignment device provided in this embodiment, in which the path and direction of light transmission are shown by a solid line with arrows, and the path and direction of data transmission are shown by a dotted line with arrows, The imaging device is shown by the dashed box; figure 2 (a), (b), and (c) respectively show three types of registration marks applicable to the mask alignment device; image 3 for figure 2 Schematic diagram of the nesting principle of the third nesting mark in (c).

[0072] see Figure 1 to Figure 3 combine Figure 4 and Figure 6 As shown, the mask alignment system provided in this embodiment includes a data processing device 7, an image acquisition device 6, a workbench 1 for supporting a reference plate 9, a mask table 3 for supporting a reticle 8, and an imaging device and projection objective lens ...

Embodiment 2

[0107] Embodiment 2 provides a mask alignment method. This embodiment includes the mask alignment device in Embodiment 1. The technical features of the mask alignment device disclosed in Embodiment 1 are also applicable to this embodiment. Example 1 The technical features of the disclosed mask alignment device will not be described repeatedly.

[0108] Figure 4 Schematic diagram of the field of view under the alignment analysis step of the mask alignment method provided in this embodiment;

[0109] Figure 5 and Figure 6 Schematic diagrams of the principles of the two alignment analysis steps provided in this embodiment are respectively shown.

[0110] combine Figure 1 to Figure 3 and see Figure 4 to Figure 6 As shown, the mask alignment method provided in this embodiment specifically includes the following steps:

[0111] Projection imaging: place the reticle 8 on the mask table 3 so that the mask mark 80 on the reticle 8 falls into the object-side field of view of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com