Preparation method ofc

A fuel cell cathode and heterogeneous structure technology, applied in battery electrodes, structural parts, circuits, etc., can solve the problems of high preparation cost and complicated preparation method, and achieve the effects of low preparation cost, simple preparation method and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

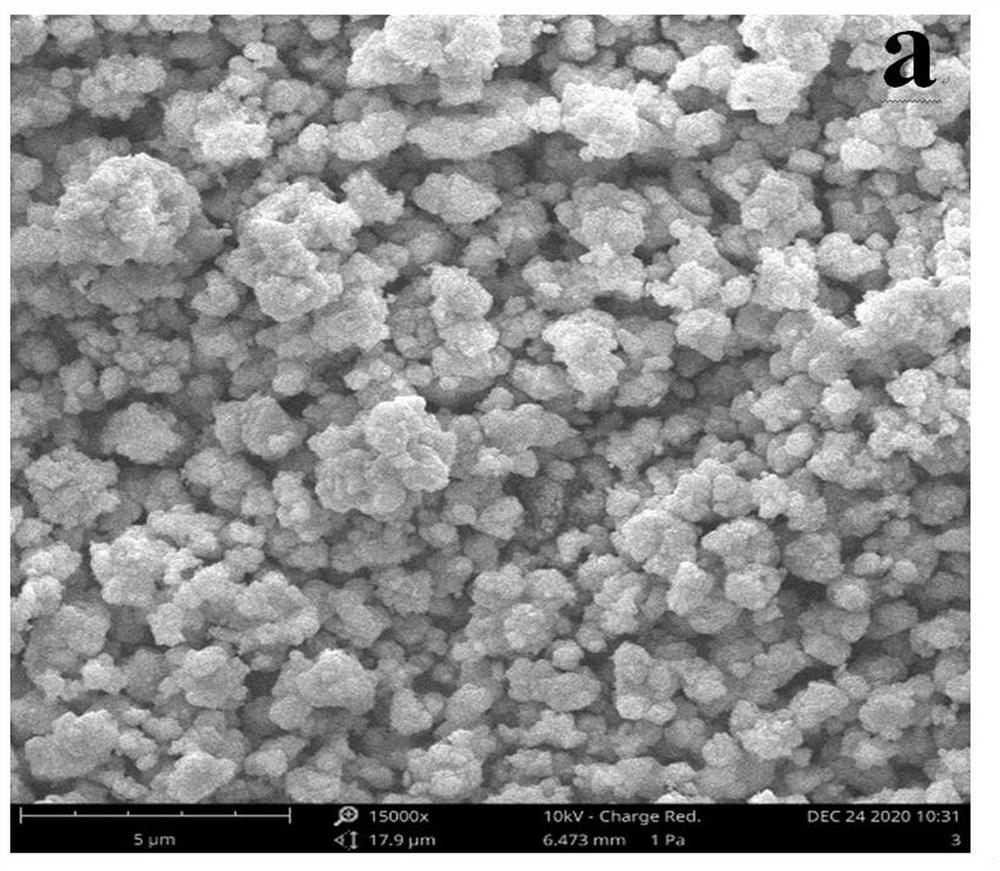

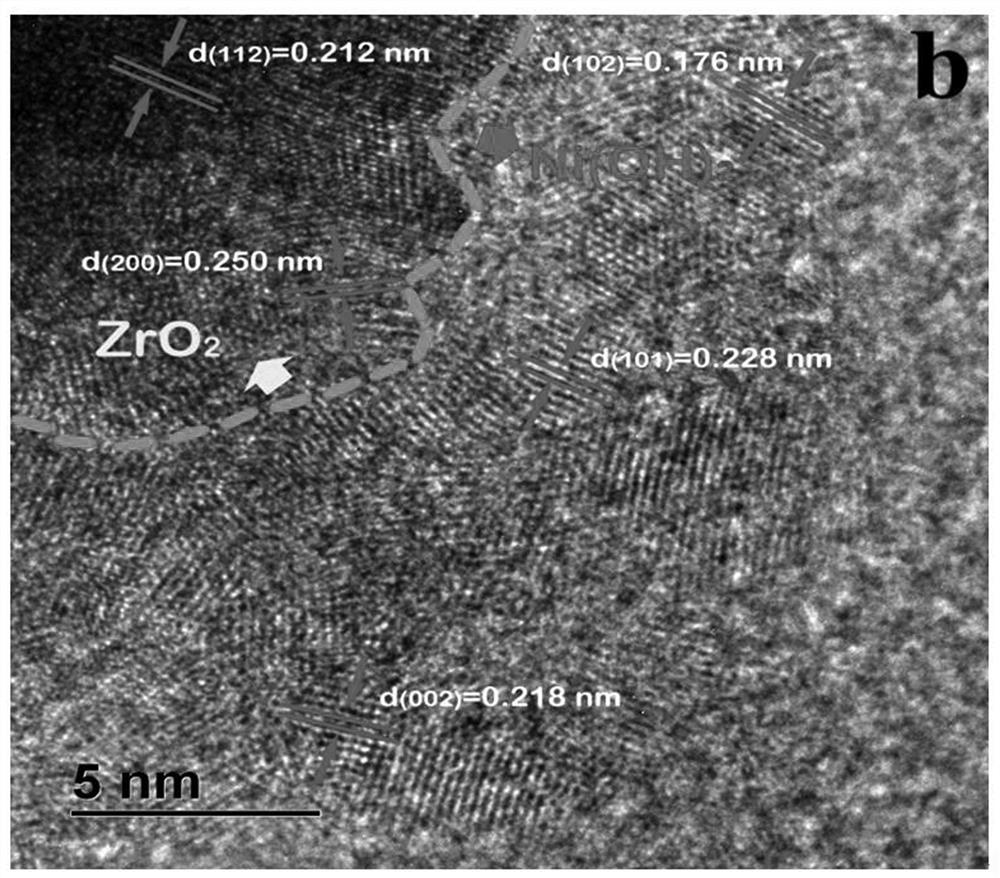

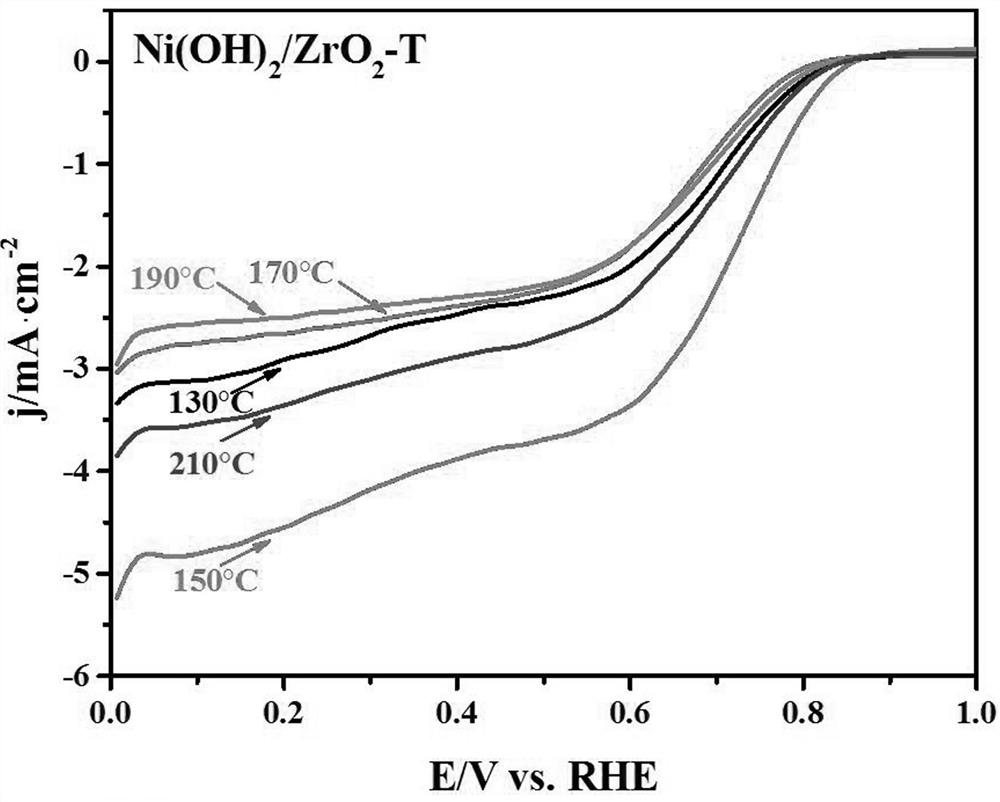

[0032] a Ni(OH) 2 ZrO 2 The preparation method of heterostructure fuel cell cathode oxygen reduction catalyst is as follows:

[0033] 0.75g of ZrCl 4 and 0.2g NiCl 2 Add to 50ml of ethanol and 20ml of ethanol respectively, and stir until dissolved, then mix the two evenly and move into the reaction kettle, at a certain temperature T (T=130°C, 150°C, 170°C, 190°C, 210°C) Solvothermal reaction was carried out for 12h. Centrifuge the reaction mixture at 9000 rpm for 10-20 minutes in a centrifuge, wash the obtained product 4-6 times with water and ethanol, and then dry it at 60-80°C for a period of time. 0.1 g of the dried crude product was added to 40 ml of ethanol, and the mixture was sonicated in a sonicator for 6 h. The mixture after ultrasonic stripping was centrifuged at 9000 rpm for 10-20 minutes in a centrifuge, and the obtained product was washed 4-6 times with water and ethanol. Finally, dry for a period of time at 60-80°C.

[0034] The obtained sample is Ni(OH) ...

Embodiment 2

[0036] a Ni(OH) 2 ZrO 2 The preparation method of heterostructure fuel cell cathode oxygen reduction catalyst is as follows:

[0037] 0.75g of ZrCl 4 and 0.2g NiCl 2 Add to 50ml of ethanol and 20ml of ethanol respectively, and stir until dissolved, then mix the two evenly and move them into the reaction kettle, carry out solvothermal reaction at 150 ℃, maintain t (t=3h, 6h, 9h, 12h, 24h ). Centrifuge the reaction mixture at 9000 rpm for 10-20 minutes in a centrifuge, wash the obtained product 4-6 times with water and ethanol, and then dry it at 60-80° C. for a period of time. 0.1 g of the dried crude product was added to 40 ml of ethanol, and the mixture was sonicated in a sonicator for 6 h. The mixture after ultrasonic stripping was centrifuged at 9000 rpm for 10-20 minutes in a centrifuge, and the obtained product was washed 4-6 times with water and ethanol. Finally, dry for a period of time at 60-80 °C.

[0038] The obtained sample is Ni(OH) 2 / ZrO 2 Heterostructur...

Embodiment 3

[0040] a Ni(OH) 2 ZrO 2 The preparation method of heterostructure fuel cell cathode oxygen reduction catalyst is as follows:

[0041] 0.75g of ZrCl 4 and 0.2g NiCl 2 Add to 50ml of ethanol and 20ml of ethanol respectively, and stir until dissolved, then mix the two evenly and transfer to a reaction kettle, and carry out solvothermal reaction at 150°C for 12h. Centrifuge the reaction mixture at 9000 rpm for 10-20 minutes in a centrifuge, wash the obtained product 4-6 times with water and ethanol, and then dry it at 60-80° C. for a period of time. 0.1 g of the dried crude product was added to 40 ml of ethanol, and the mixture was sonicated in a sonicator for Ut hours (Ut = 0h, 3h, 6h, 9h, 12h). The mixture after ultrasonic stripping was centrifuged at 9000 rpm for 10-20 minutes in a centrifuge, and the obtained product was washed 4-6 times with water and ethanol. Finally, dry for a period of time at 60-80°C.

[0042] The obtained sample is Ni(OH) 2 / ZrO 2 Heterostructure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com