Microencapsulated high-temperature resistant thermo-oxidating light-colored terpine resin and preparation method thereof

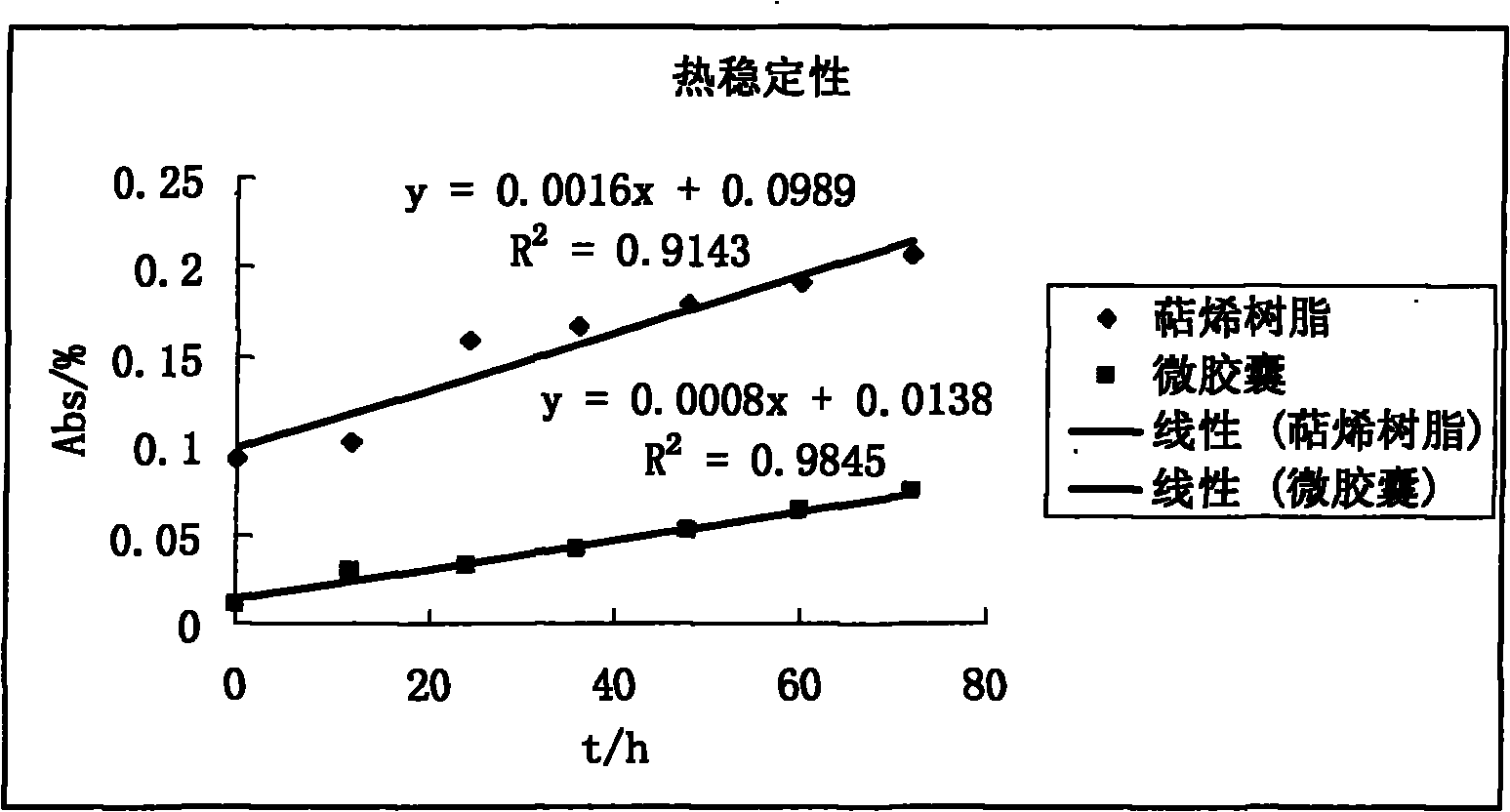

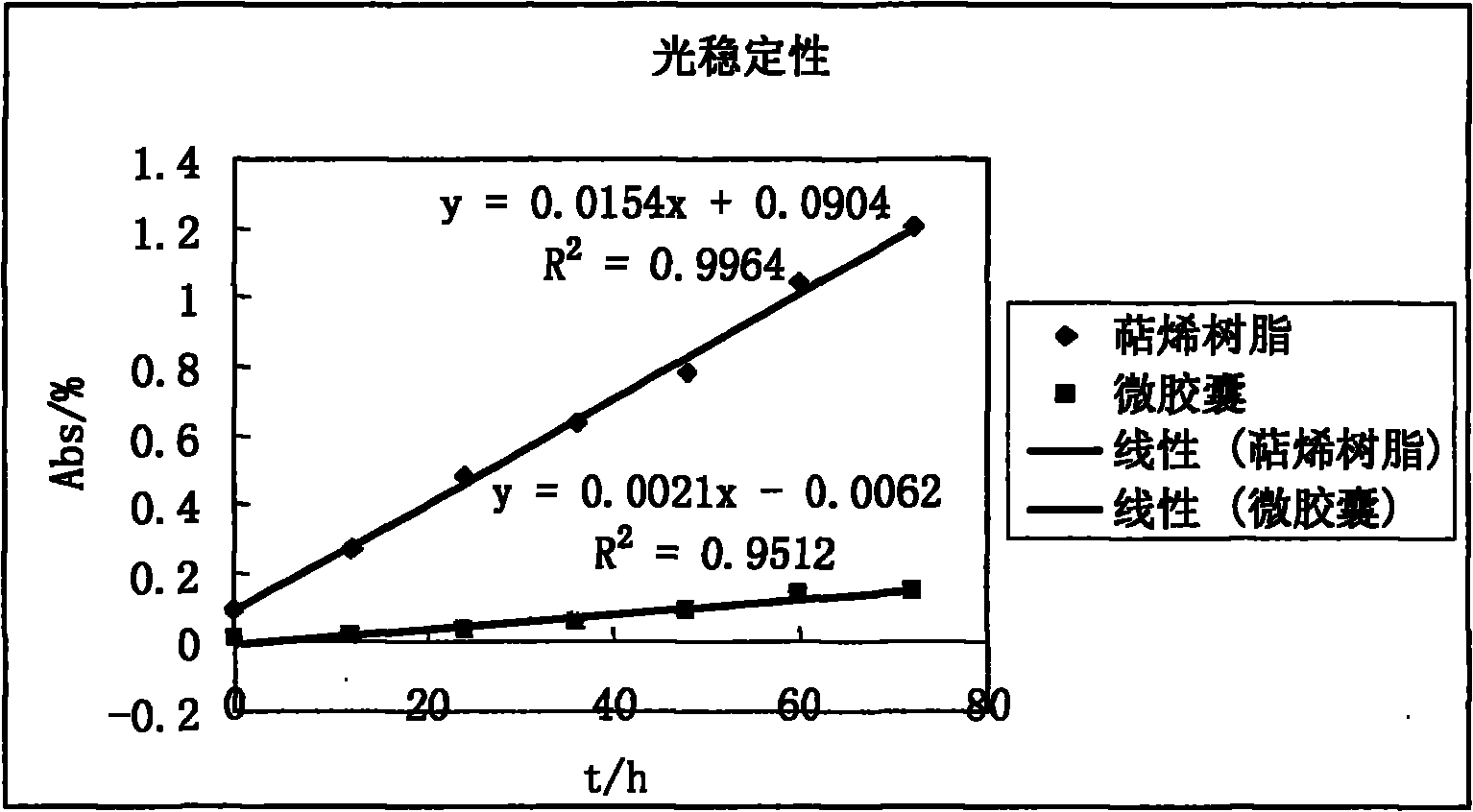

A terpene resin and microencapsulation technology, which is applied in the field of microencapsulated terpene resin products and its preparation, can solve problems such as darkening of color, achieve the effects of inhibiting oxidation, improving thermal oxygen stability, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Preparation steps of microcapsules

[0023] (1) Preparation of urea-formaldehyde prepolymer: urea and formaldehyde added in a reactor equipped with a stirrer and a heater, the weight ratio of 30-60% formaldehyde solution and solid urea is 1.5, every kilogram of solid urea Add 2 kg of water to dissolve, turn on the heater and stirrer, slowly drop 1mol / L NaOH into the reaction kettle, the temperature rises slowly until the temperature in the bottle reaches 70°C and the pH value of the solution is 8.0, then keep warm for 1h Then stop heating to get urea.

[0024] (2) Preparation of terpene resin emulsion: According to the ratio of adding 10 liters of cyclohexane per kilogram of terpene resin, first grind the terpene resin into powder, then add cyclohexane to stir and dissolve; add 0.4 kg of OP-10 5 liters of water were stirred and dissolved, and then the aqueous solution was poured into the terpene resin solution and stirred to fully emulsify the solution, and the emulsif...

Embodiment 2

[0029] Preparation steps of microcapsules

[0030] (1) Preparation of urea-formaldehyde prepolymer: urea and formaldehyde added in a reactor equipped with a stirrer and a heater, the weight ratio of 30-60% formaldehyde solution and solid urea is 1.0, every kilogram of solid urea Add 2 kg of water to dissolve, turn on the heater and agitator, and slowly add 0.5mol / L NaoH dropwise to the reaction kettle, and the temperature rises slowly until the temperature in the bottle reaches 70°C and the pH value of the solution is 8.0. Stop heating after 1h to obtain urea.

[0031] (2) Preparation of terpene resin emulsion: According to the ratio of adding 10 liters of cyclohexane per kilogram of terpene resin, first grind the terpene resin into powder, then add cyclohexane and stir to dissolve; in addition, 0.6 kg of dodecyl Add 5 liters of water to sodium benzenesulfonate and stir to dissolve, then pour the aqueous solution into the terpene resin solution and stir to fully emulsify the ...

Embodiment 3

[0036] Preparation steps of microcapsules

[0037] (1) Preparation of urea-formaldehyde prepolymer: Add a certain proportion (1.5, 1.25, 1.0) of urea and formaldehyde into a 250ml three-necked bottle, add an appropriate amount of water to dissolve the urea, and stir with electricity. Add an appropriate amount of 0.5mol / L NaOH dropwise to the three-necked flask to adjust the pH value of the solution to 8.0, turn on the electricity to slowly increase the temperature of the oil bath until the temperature in the bottle reaches 70°C, and start to keep warm, and stop heating after keeping warm for 1 hour.

[0038] 2) Preparation of terpene resin emulsion: take the terpene resin dissolved in toluene as the oil phase, and the O / W type stable emulsion with the aqueous solution containing Tween-80 as the water phase: weigh 3.5 g of the terpene resin ground into powder In a 150ml beaker, add an appropriate amount of toluene and stir to dissolve with a glass rod; weigh 4%-8% Tween-80 in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com