High-viscosity battery slurry coating device and coating method thereof

A technology of coating device and coating method, which is applied in the direction of device and coating for coating liquid on the surface, can solve the problems of agglomeration of active material and conductive agent, increase the internal resistance of lithium battery, solvent recovery, etc., and reduce production. cost, the effect of reducing polarization and internal resistance, and reducing the degree of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

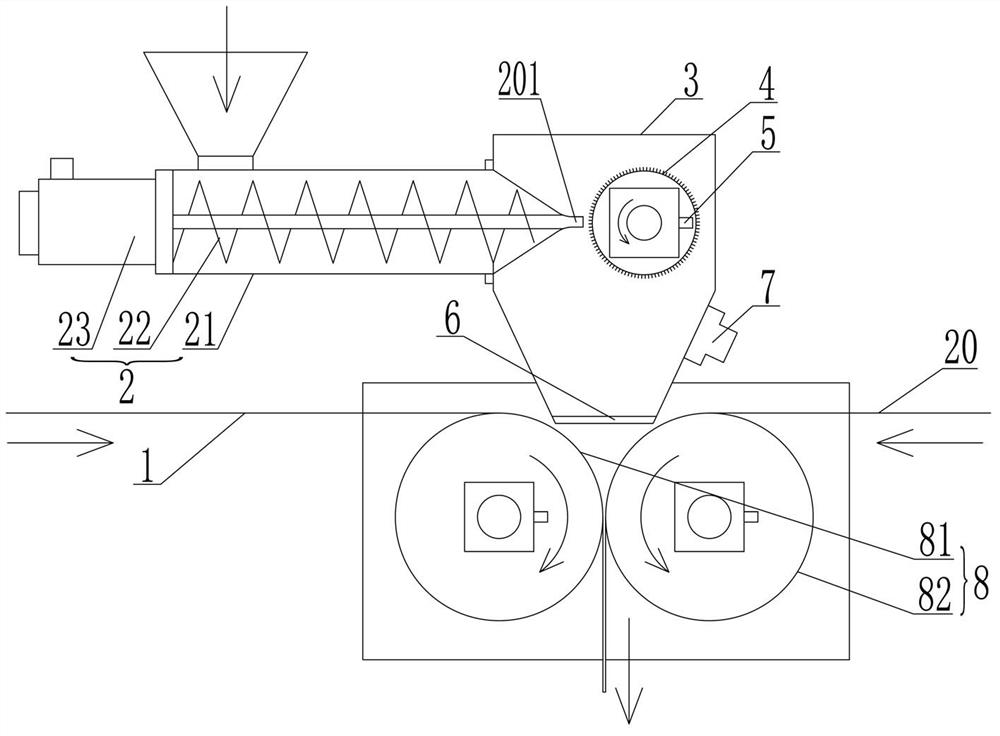

[0058] Example 1 High-viscosity battery slurry coating device

[0059] This example figure 1 As shown, a high-viscosity battery slurry coating device includes a coating counter-roll machine 8 for rolling the battery slurry on the current collector 1 and a coating counter-roll machine 8 for inputting the battery slurry into the coating counter-roll machine 8 The feeding device also includes an anti-sticking device to prevent the battery slurry from sticking to the coating roller machine 8 . The feeding device is a device for holding battery slurry, and the high-viscosity battery slurry is fed through the feeding device, so that the battery slurry enters the coating roller machine 8, and the battery slurry is coated by the coating roller machine 8. The material is coated on the current collector 1. During the coating process, the anti-sticking device can effectively prevent the battery slurry from sticking to the coating roller of the coating roller machine 8.

[0060] The fee...

Embodiment 2

[0065] Example 2 High-viscosity battery slurry coating device

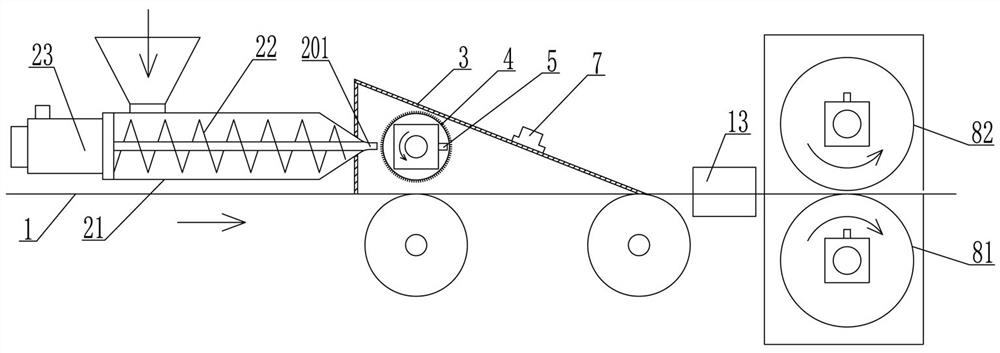

[0066] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is the structure of the feed hopper 3, the arrangement of the feed hopper 3 and the structure of the anti-sticking device.

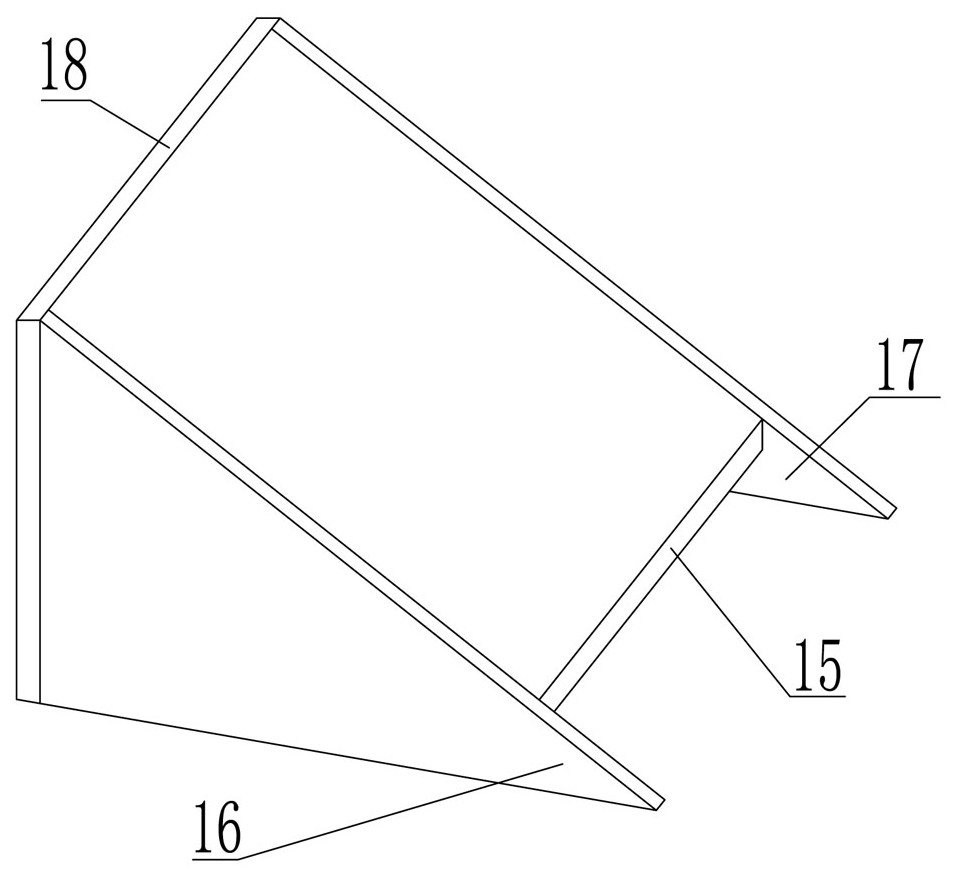

[0067] Such as figure 2 As shown, the feed hopper 3 of this embodiment is arranged parallel to the current collector 1, that is, the left and right direction of the feed hopper 3 is its length direction, and the length direction of the feed hopper 3 is the same as the movement direction of the current collector 1, as shown in image 3 As shown, the feed hopper 3 includes a first baffle 15 disposed opposite to the current collector 1 , a second baffle 16 and a third baffle 17 respectively fixed on both sides of the first baffle 15 . The first baffle plate 15 is inclined from high to low along the moving direction of the current collector 1, forming a slope. A gap is provided between the end...

Embodiment 3

[0070] Example 3 High-viscosity battery slurry coating device

[0071] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is the structure of the feed hopper 3, the arrangement of the feed hopper 3 and the structure of the anti-sticking device.

[0072] Such as Figure 4 As shown, the feeding hopper 3 of this embodiment is arranged in parallel with the current collector 1, that is, the left and right direction of the feeding hopper 3 is its length direction, and the length direction of the feeding hopper 3 is the same as the moving direction of the current collector 1, so The feed hopper 3 is a shell, and the feed hopper 3 is also provided with a blocking roller 9 for preventing battery slurry from flying upwards. The blocking roller 9 is driven by a second motor 10. The gap between the wheels 4 is 0.1-5 mm, and the gap used in this embodiment is 3 mm, which can not only make the spur wheels 4 rotate normally, but also prevent the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com