Hot-press and cold-press forming process for automobile safety air bags

A technology of automobile safety and cold press forming, which is applied in the direction of household components, household appliances, and other household appliances, can solve the problems of low processing efficiency, unsatisfactory volume reduction rate, and difficulty in meeting the designer's design requirements, etc., to achieve high compression molding Efficiency, small deformation rate, not easy to rebound effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

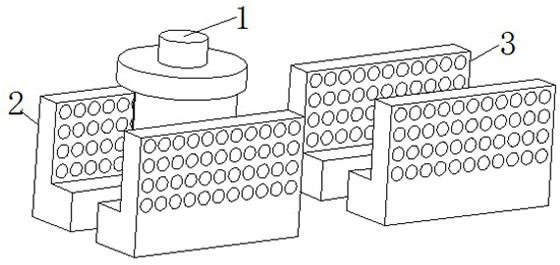

[0021] Such as figure 1 Shown, a kind of automobile safety air bag hot pressing and cold pressing molding process of the present invention comprises the following steps:

[0022] S1. Fold the air bag with the support ring installed;

[0023] S2. The robot sends the folded air bag in S1 to the hot pressing device for pressurization, heating and shaping;

[0024] S3. The robot sends the hot-pressed air bag to the cold-pressing device for heat dissipation, cooling and shaping;

[0025] S4. Perform quality inspection on the air bags taken out in S3, and package the products that pass the quality inspection, that is, complete a production.

[0026] Wherein, in said S2, the hot pressing device includes a molding mechanism 1 and a heating wind cover 2, and the heating wind cover 2 adopts an electric heating method, and the maximum temperature of the electric heating can reach 180°C.

[0027] Wherein, the molding mechanism 1 after being pressurized and heated and shaped by S2 is se...

Embodiment 2

[0033] Such as figure 1 Shown, a kind of automobile safety air bag hot pressing and cold pressing molding process of the present invention comprises the following steps:

[0034] S1. Fold the air bag with the support ring installed;

[0035] S2. The robot sends the folded air bag in S1 to the hot pressing device for pressurization, heating and shaping;

[0036] S3. The robot sends the hot-pressed air bag to the cold-pressing device for heat dissipation, cooling and shaping;

[0037] S4. Perform quality inspection on the air bags taken out in S3, and package the products that pass the quality inspection, that is, complete a production.

[0038] Wherein, in said S2, the hot pressing device includes a molding mechanism 1 and a heating wind cover 2, and the heating wind cover 2 adopts an electric heating method, and the maximum temperature of the electric heating can reach 180°C.

[0039] Wherein, the molding mechanism 1 after being pressurized and heated and shaped by S2 is se...

Embodiment 3

[0045] Such as figure 1 Shown, a kind of automobile safety air bag hot pressing and cold pressing molding process of the present invention comprises the following steps:

[0046] S1. Fold the air bag with the support ring installed;

[0047] S2. The robot sends the folded air bag in S1 to the hot pressing device for pressurization, heating and shaping;

[0048] S3. The robot sends the hot-pressed air bag to the cold-pressing device for heat dissipation, cooling and shaping;

[0049] S4. Perform quality inspection on the air bags taken out in S3, and package the products that pass the quality inspection, that is, complete a production.

[0050] Wherein, in said S2, the hot pressing device includes a molding mechanism 1 and a heating wind cover 2, and the heating wind cover 2 adopts an electric heating method, and the maximum temperature of the electric heating can reach 180°C.

[0051] Wherein, the molding mechanism 1 after being pressurized and heated and shaped by S2 is se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com