Biological membrane denitrification sewage treatment equipment based on centrifugal effect

A kind of sewage treatment equipment and centrifugation technology, which is applied in the direction of centrifugal separation of water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of reducing the treatment effect, affecting the efficiency of sewage purification, surface layer Easy to accumulate sludge and other problems, to achieve the effect of improving the filtering effect, good user experience and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

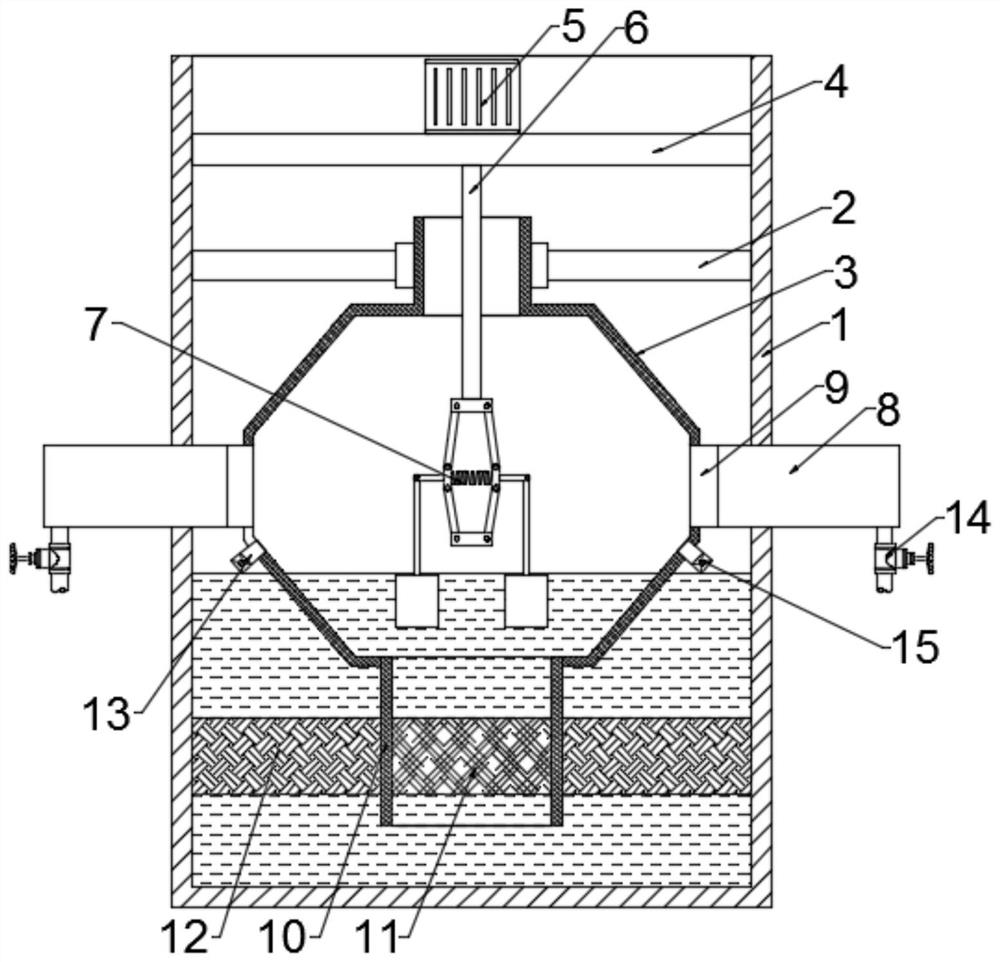

[0027] Example 1: Please refer to Figure 1-4 , a biofilm denitrification sewage treatment device based on centrifugal action, comprising an outer box 1, the inner side of the outer box 1 is fixedly connected with a horizontal fixing rod 2, and the inner end of the horizontal fixing rod 2 is connected with an inner box 3 through a connecting block, A mounting bracket 4 is fixedly connected to the top of the inner side of the outer box 1, a motor 5 is fixedly connected to the top of the mounting bracket 4, and a longitudinal shaft 6 is fixedly connected to the rotor of the motor 5;

[0028] During use, the waste water is injected between the outer box body 1 and the inner box body 3, and then the motor 5 can be turned on, and the rotation of the motor 5 drives the rotation of the longitudinal shaft 6;

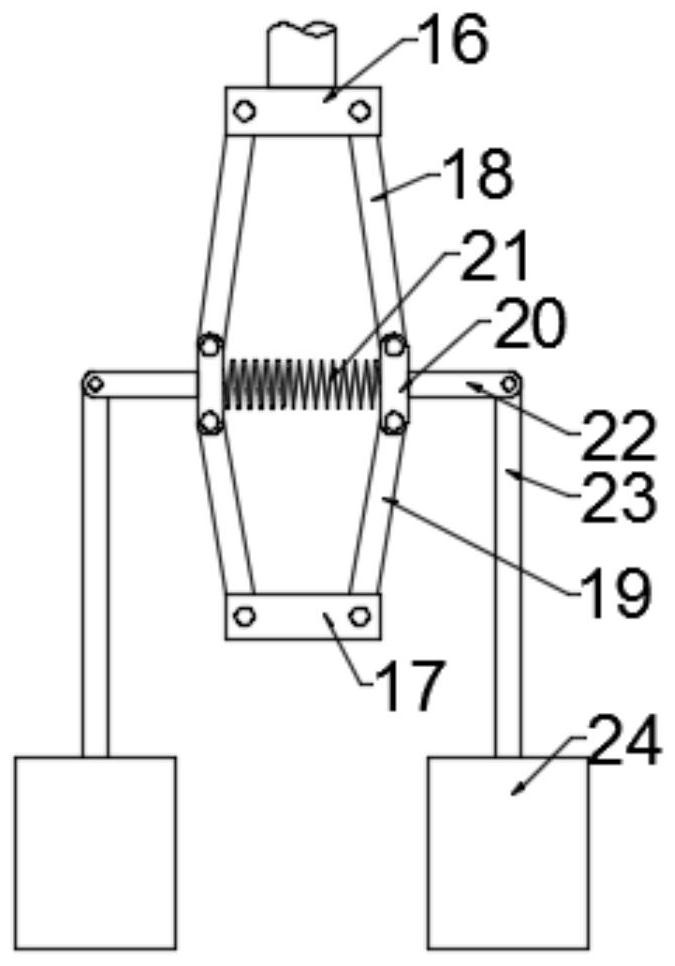

[0029] The lower end of the longitudinal rotating shaft 6 runs through the inner box 3 and is connected with a centrifugal processing assembly 7, and the middle part of the oute...

Embodiment 2

[0040] Embodiment 2: This embodiment is a further improvement of the previous embodiment: when the swinging centrifugal rod 23 is in a vertical state, the top of the centrifugal box 24 is located below the return pipe 13 .

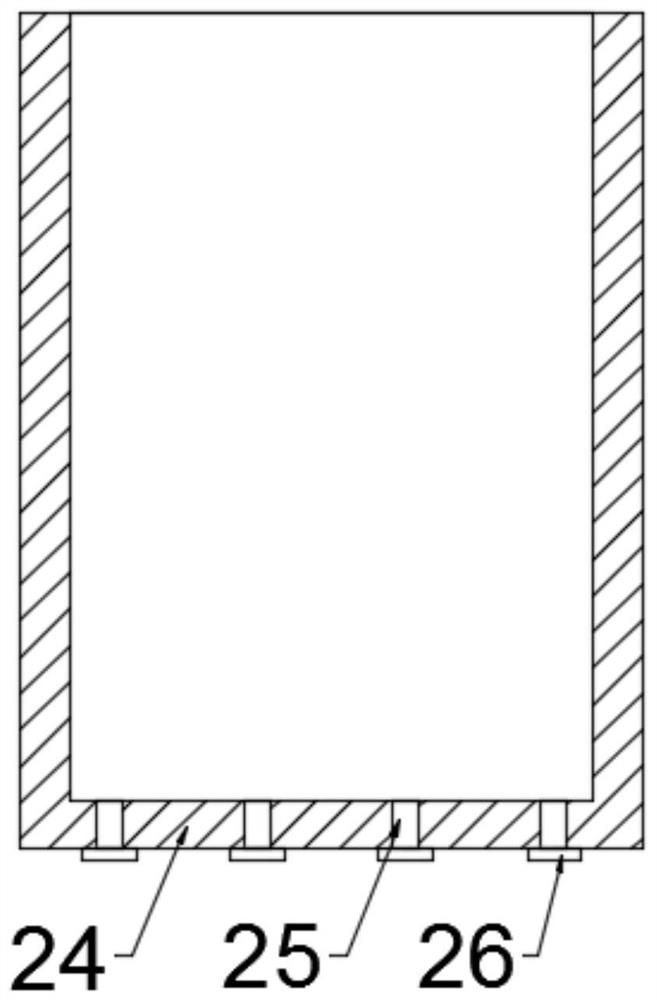

[0041] The working principle of the present invention is: when in use, the waste water is injected between the outer box 1 and the inner box 3, and then the motor 5 can be turned on, and the rotation of the motor 5 drives the rotation of the longitudinal shaft 6, and the rotation of the longitudinal shaft 6 can pass through the centrifugal processing assembly The centrifugal effect of 7 lifts the sewage and pours it on the MBR membrane module 9, and enters the drain pipe 8 through the MBR membrane module 9 under the centrifugal effect, and then the clean water can be discharged. During the rotation process, the centrifugal processing assembly 7 will make the centrifugal box body 24 perform centrifugal motion with the increase of the rotation speed of the moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com