Rust inhibitor for preventing rolling mill cavity from being corroded during strip steel production by hot continuous rolling unit

A technology of hot continuous rolling and rust inhibitors, applied in the field of rust inhibitors and rust inhibitors for preventing corrosion of rolling mill cavities, can solve problems affecting the quality of steel coils, corrosion of rolling mill cavities, etc. Quality, prevention and effect of pressing-in defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The invention provides a rust inhibitor for preventing the corrosion of the rolling mill cavity when a hot continuous rolling unit produces strip steel, which consists of triethanolamine borate, melamine formaldehyde resin, polyethylene glycol, sodium benzoate, isooctyl alcohol polyoxyethylene Ether and deionized water form, and in described rust inhibitor, the mass percent concentration of each material is as follows:

[0031]

[0032]

[0033] The preparation method of the present invention is that the substances are weighed according to the above-mentioned mass percentage, and then mixed uniformly before use.

Embodiment 2

[0034] Embodiment 2 adhesion: (pull off method) 10Mpa, adhesion test method (GB / T5210-2006):

[0035] 1. The substrate is sandblasted steel plate with a roughness of 40-60um.

[0036] 2. The rust inhibitor is painted with the original solution, and it can be sprayed evenly.

[0037] 3. After 2 hours of natural drying, the drying condition is 80°C, 1h forced baking and curing, and then placed at room temperature for 24 hours, then coated with graphene-coated series functional material BZ-4405, 80°C, 1h forced baking and curing to test the adhesion (pull off method).

[0038]

[0039] As can be seen from the above table, the present invention has stronger adhesion.

Embodiment 3

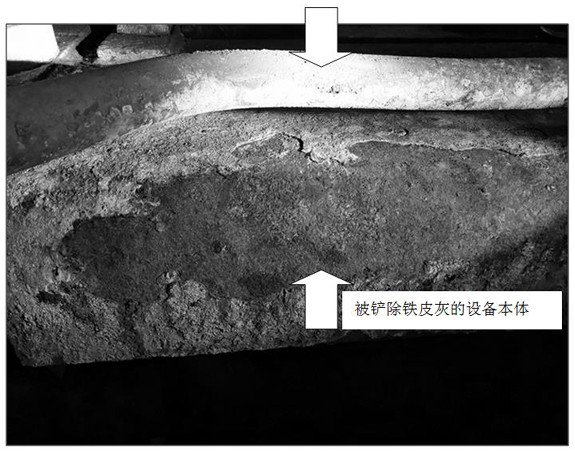

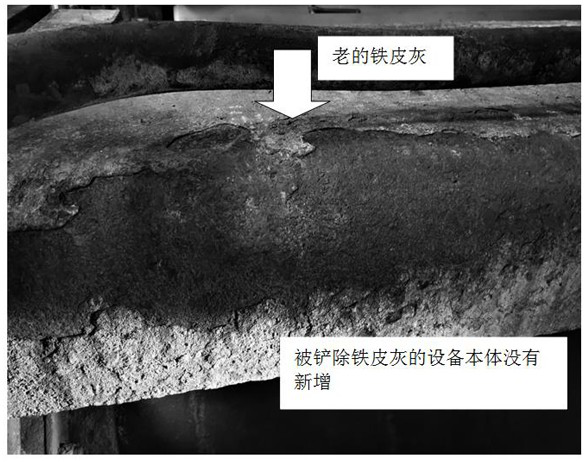

[0041] like figure 1 As shown, on August 18, 2020, a rust inhibitor was partially applied to the beam of Baosteel Zhanjiang Iron and Steel Hot Rolling Mill. The white part in the picture is the iron ash, and the red part is the equipment body from which the iron ash was removed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com