Anti-virus knitted fabric and production method thereof

A production method and technology for knitted fabrics, applied in the directions of knitting, weft knitting, fabric surface trimming, etc., can solve problems such as bursting strength of anti-virus fabrics that are not involved, and achieve the effects of good performance and good wearing comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0082] (1) Blowing and carding: Mix, loosen and remove impurities from the selected acrylic and carbon fiber raw materials through a cleaning machine; feed the cleaned acrylic and carbon fibers into the carding machine, The impurities and non-spinning fibers are further removed, and the sliver is obtained; wherein, in the acrylic chloride fiber carbon fiber, the weight ratio of acrylic chloride fiber to activated carbon is 85:15; the linear density of the acrylic chloride fiber carbon fiber is 3.6dtex, and the linear The density deviation is 9%, the breaking strength is 1.6cN / dtex, and the breaking elongation is 25%;

[0083] (2) Sliver making: the raw sliver is made into a uniform yarn line using a pressing roller and a coiling device, wherein the speed of the front roller is 112r / min;

[0084] (3) Drawing frame: the yarn strands are sent to the drawing frame, and the sliver is obtained through the merging-drawing-mixing-sliver-forming process; wherein, the sliver ration is 3...

Embodiment 1

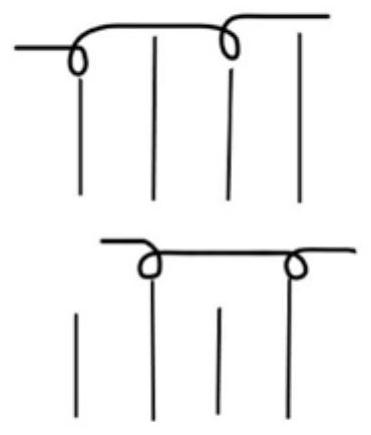

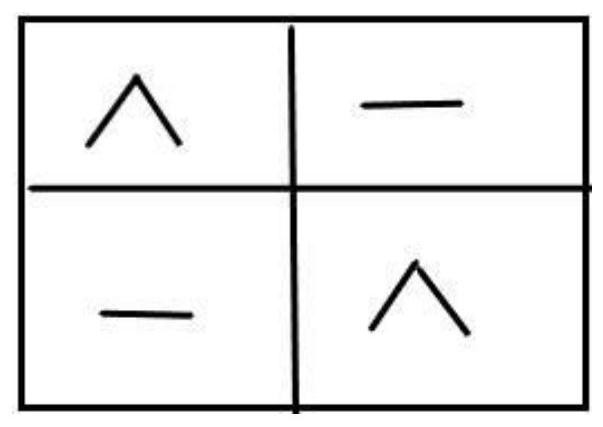

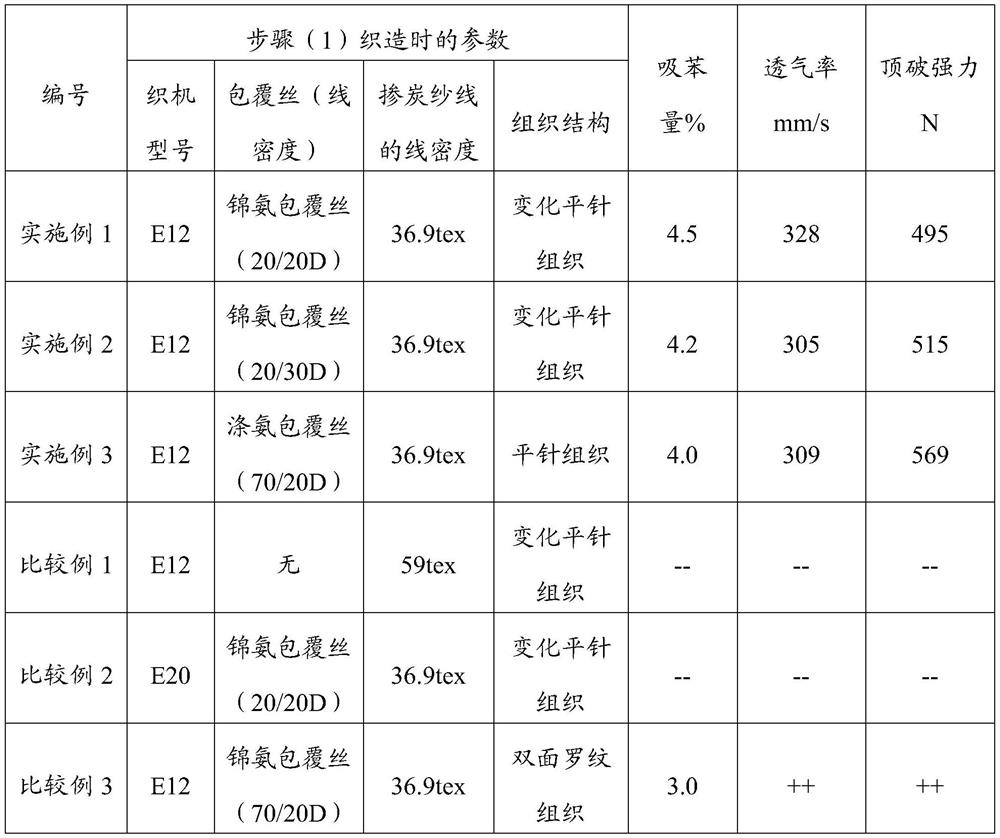

[0090] (1) Weaving: weaving the carbon-incorporated yarn and covered silk obtained in the preparation example into a knitted grey fabric; the carbon-incorporated yarn is a single yarn prepared from acrylic vinyl chloride fiber-incorporated carbon fiber; the linear density of the carbon-incorporated yarn is 36.9 tex, the covered yarn is a core-spun yarn made of spandex filament and nylon filament, that is, the covered yarn is a nylon-spandex covered yarn, and its linear density is 20 / 20D. The loom used is an E12 circular weft machine, the diameter of the loom is 34 inches, the carbon-doped yarn and the covered silk are woven in a quantity ratio of 1:1, and the weaving humidity is 75%; ,like figure 1 and figure 2 shown; the E12 circular weft machine used was purchased from Quanzhou Rongtian Knitting Machinery Co., Ltd., the specific model is RT-34×54F;

[0091] (2) Open width: the cylindrical grey fabric after weaving is cut along the width-cutting line to obtain open-width p...

Embodiment 2

[0097] The only difference from Example 1 is that the linear density of the ammonia-coated silk is 20 / 30D.

[0098] The anti-virus knitted fabric obtained in this example has a benzene absorption of 4.2%, an air permeability of 305 mm / s, and a bursting strength of 515 N.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com