Charging structure for controlling blasting tight bottom of strip mine

A technology for open-pit mines and explosives, which is applied in the mining, blasting, and special mining of open-pit mines. It can solve problems such as threatening the safety of personnel and equipment, accelerating equipment wear, unreasonable large pieces and roots, etc., and achieves a wide range of applications. Reduce root generation, good blasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

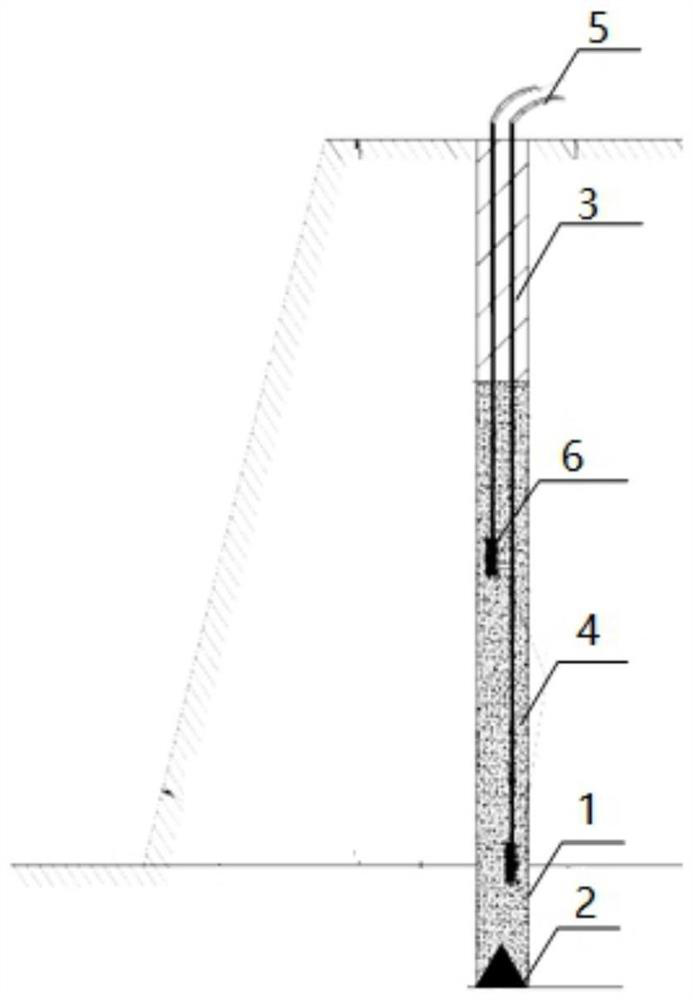

[0024] A charge structure for controlling blasting foundations in open-pit mines,

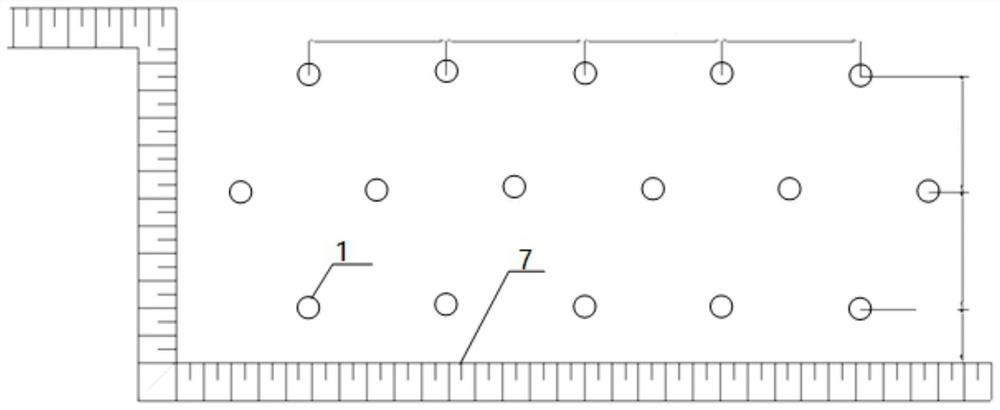

[0025] The working steps of an open-pit iron mine are 12m high, the rock weight is 2.6 tons / m3, the firmness factor is f=12-16, and the rock volume of a single blasting is 6620m3. According to the environment and geological structure characteristics of the blasting area, the blastholes are arranged by drilling 1 , Blasting the lower step slope 7 with a height of 12m, using deep hole step blasting, electric detonator-nonel 5-hole millisecond differential detonation, vertical hole layout, blast hole 1 diameter Φ165mm. Explosives adopt hydrochloric acid expanded ammonium nitrate explosives, powdery No. 2 rock emulsion explosives (for having water blast hole 1).

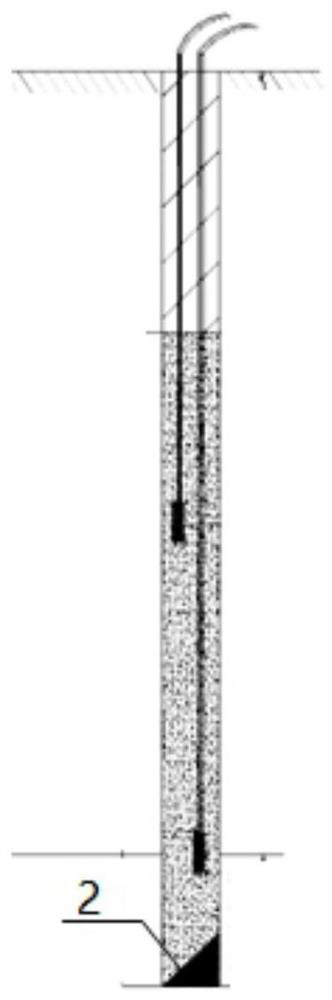

[0026] The blasting hole is 14m deep, of which the ultra-deep section is 2m long, the charging section 4 is 10m long, and the filling section 3 is 4m long. image 3 ; Blasting hole 1 adopts the method of continuous charging and double pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com