Method for predicting sintering end point according to temperature of air bellow

A technology of sintering end point and bellows, which is applied in the field of metallurgy, can solve the problem that input variables cannot be well described, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

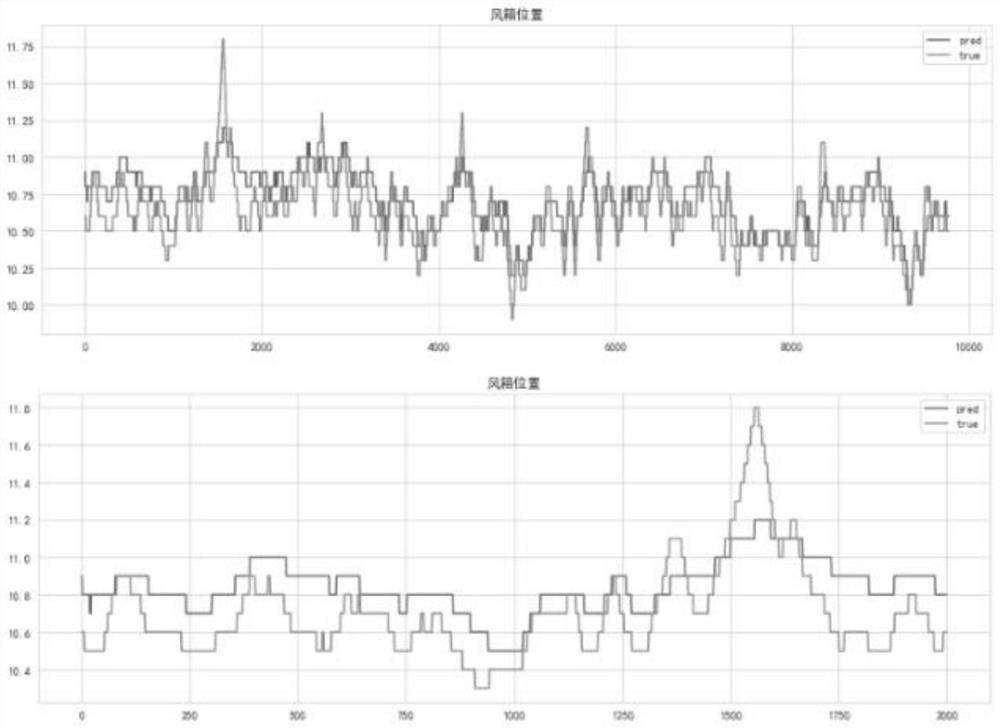

[0031] Such as Figure 1-3 As shown, the embodiment of the present invention provides a method for predicting the end point of sintering according to the wind box temperature, including the following specific content:

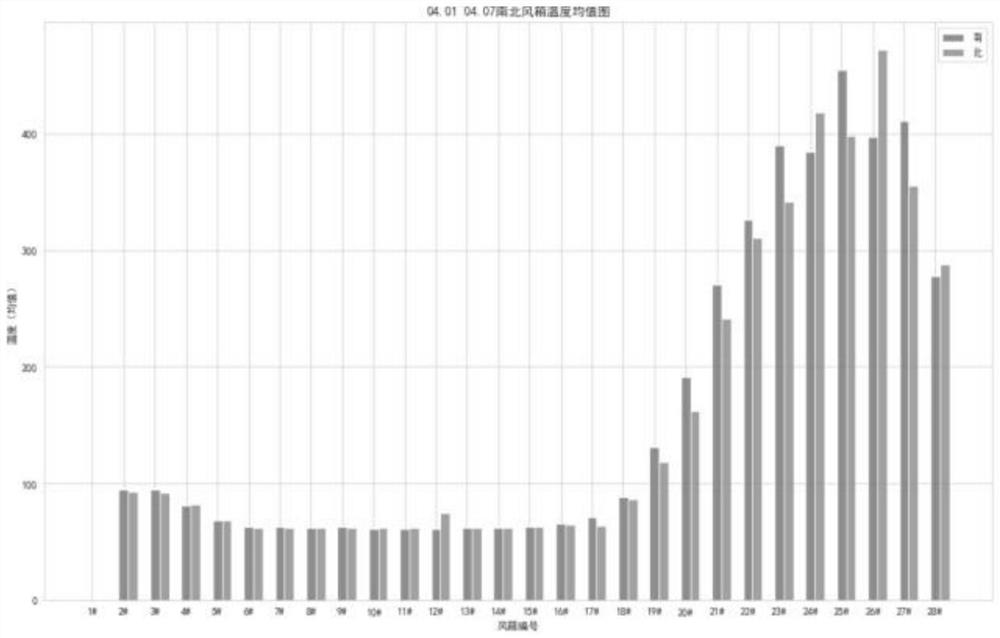

[0032] S1. Reference figure 1 , select the data of a sintering machine in a steel plant during a certain period of time, and select the detected air box exhaust gas temperature data of the 1#-28# air box to check the temperature distribution. It is generally believed that the sintering end point is near the highest temperature point ;

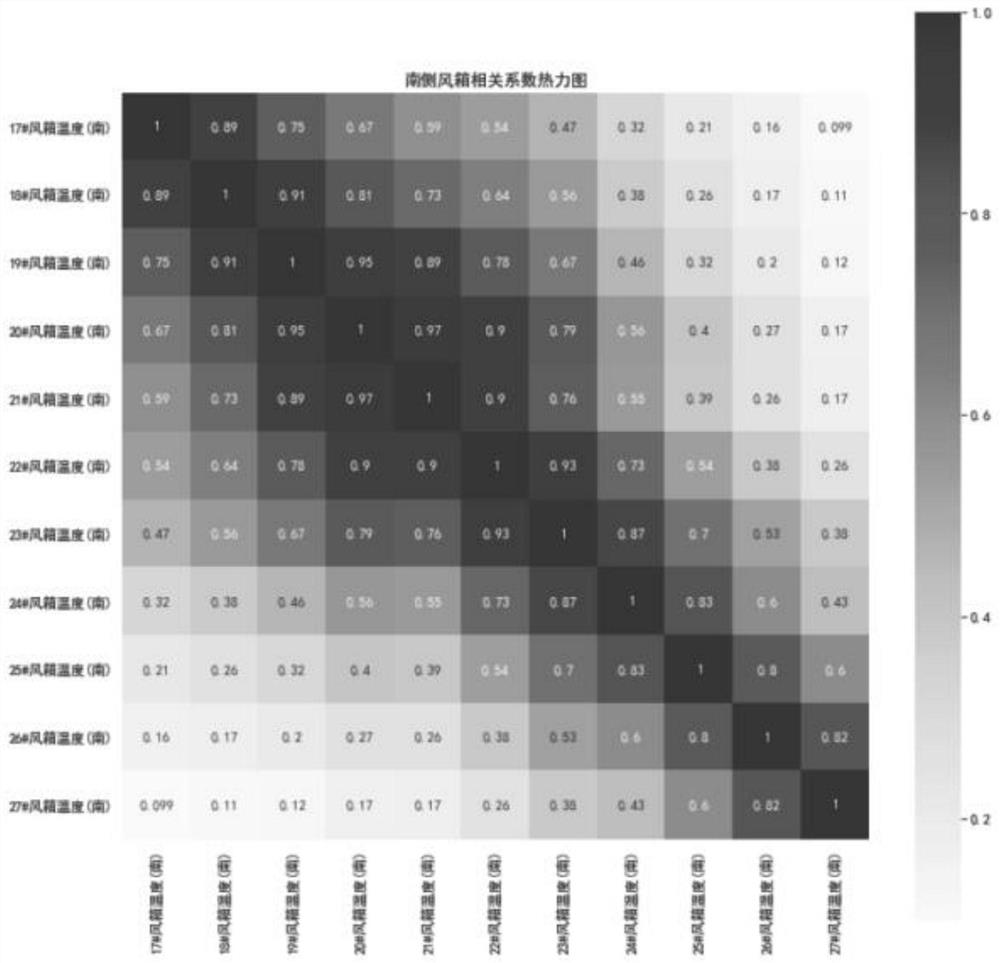

[0033] S2. Reference figure 2 , according to the position curve of the sintering end point, it can be judged that the sintering end point will appear in the middle and late stages of the bellows under normal conditions. Select the data of the bellows at the middle and back positions to check their correlation. It can be seen from the correlation thermodynamic diagram that there is a strong correlation between adjacent bellows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com